4.21 Checking rail pressure sensor

Tools required

• Diagnosis tool

1.

Place the key switch in the ON position.

2. Check the "Actual rail pressure" and "Rail pressure

sensor output voltage" on the diagnosis tool data

monitor.

3. Start the engine.

4. Change the depressed amount of the accelerator

pedal, and check the same items again.

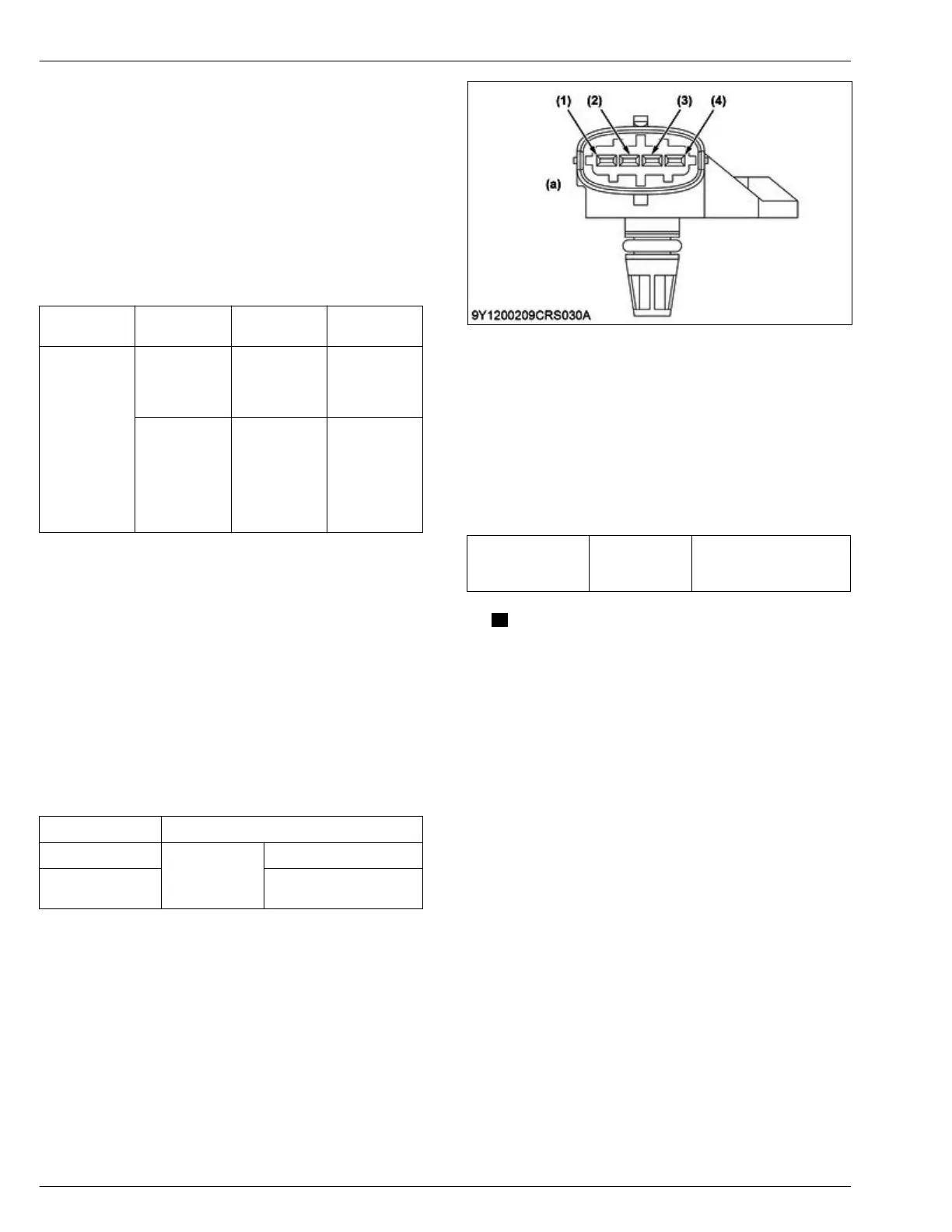

Engine state

Actual rail

pressure

Output volt-

age

Service speci-

fication

Key switch is

ON

Approx.

0 MPa

0 kgf/cm

2

0 psi

Approx. 0.3 V

After engine

start-up

Approx.

25.0 to

150 MPa

255 to

1520 kgf/cm

2

3630 to

21700 psi

Approx. 0.7 to

2.5 V

4.22 Checking boost pressure

sensor

Tools required

• Circuit tester

1.

Place the key switch in the ON position.

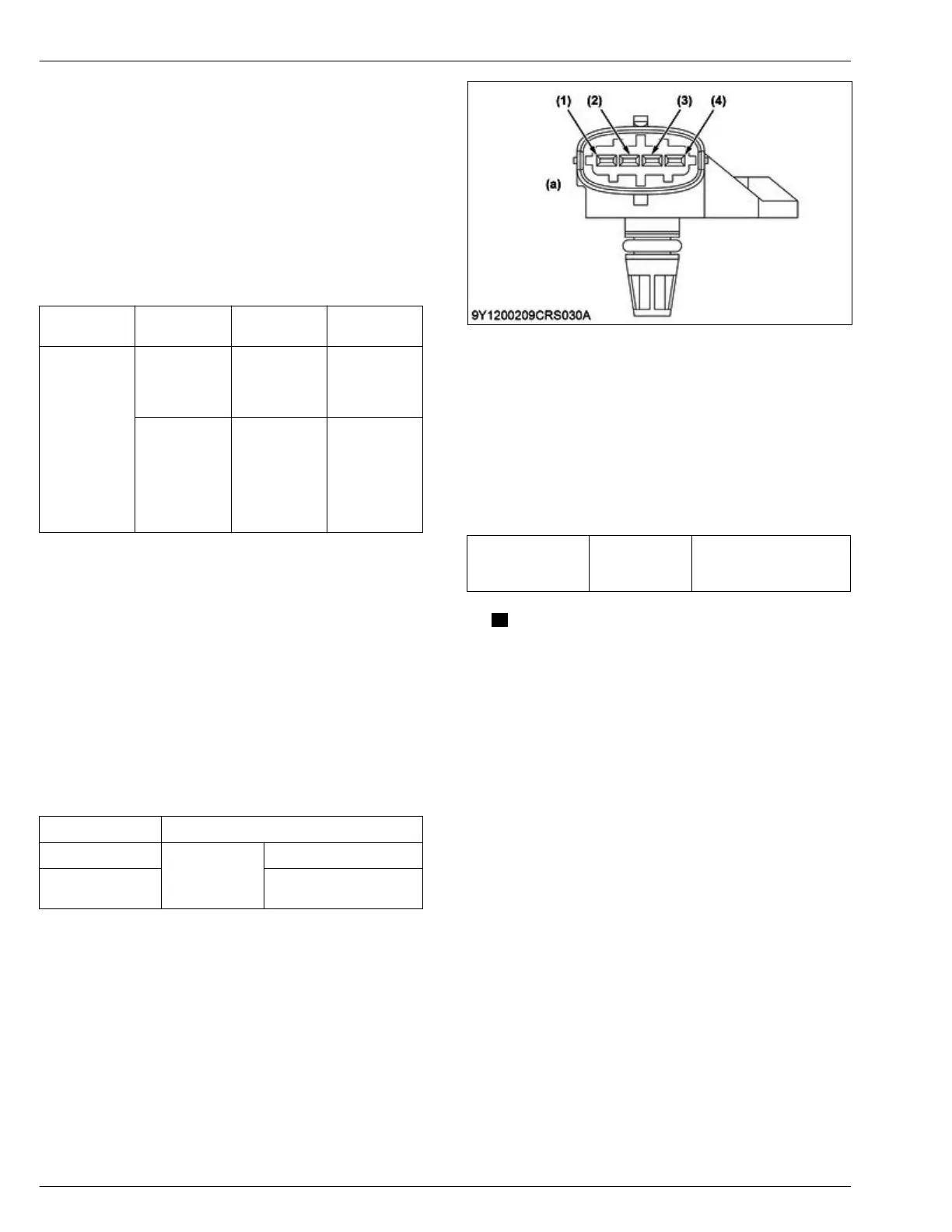

2. Measure the voltage between the boost pressure

sensor terminal (1) and (4) connector from the

wiring harness side.

3. Start the engine, change the depressed amount of

the accelerator pedal, and check the same items

again.

Engine state Output voltage

Key switch ON

Service specifi-

cation

Approx. 1.0 V

After engine start-

up

Approx. 1.0 to 2.2 V

(1) Terminal pressure signal

(2) T

erminal 5V

(3) Terminal temperature signal

(4) Terminal ground

(a) Pin assginment

4. Set the key switch to the OFF position.

5. Disconnect the

boost pressure sensor connector

from the socket.

6. Place the key switch in the ON position.

7. Measure the voltage between boost pressure

sensor terminal (2) and (4) connector (from the

wiring harness side).

Terminal 5V (2)

and terminal

ground (3)

Service specifi-

cation

Approx. 5 V

NOTE

• If the

measurement is out of the service

specification, replace the boost pressure

sensor.

4. ENGINE

SERVICING

4. Checking and adjusting

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...