5. Check

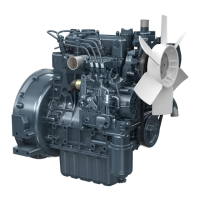

the subsequent valve clearance (5) at the

mark

[1TC] with a feeler gauge.

NOTE

• If the

clearance is out of the service

specifications, adjust with the adjusting

screw (3).

• Tighten the lock nut (4) of the adjusting

screw.

Valve clearance

(Cold)

Service specifi-

cation

0.18 to 0.22 mm

0.0071 to 0.0086 in.

Adjustable cylinder loca-

tion of piston

Valve arrangement

3 cylinder 4 cylinder

Intake

Ex-

haust

Intake

Ex-

haust

When No. 1 pis-

ton is at

compression top

dead center.

1 ☆

☆ ☆ ☆

2 ☆ ☆

3 ☆ ☆

4 - -

When No. 1 pis-

ton is at overlap

position.

1

2 ☆ ☆

3 ☆ ☆

4 - - ☆ ☆

(3) Adjusting screw

(4) Lock nut

(5)

Valve clearance

6. Install the removed parts.

Tightening tor-

que

Cylinder head cov-

er screw

6.86 to 11.3 N⋅m

0.700 to 1.15 kgf⋅m

5.06 to 8.33 lbf⋅ft

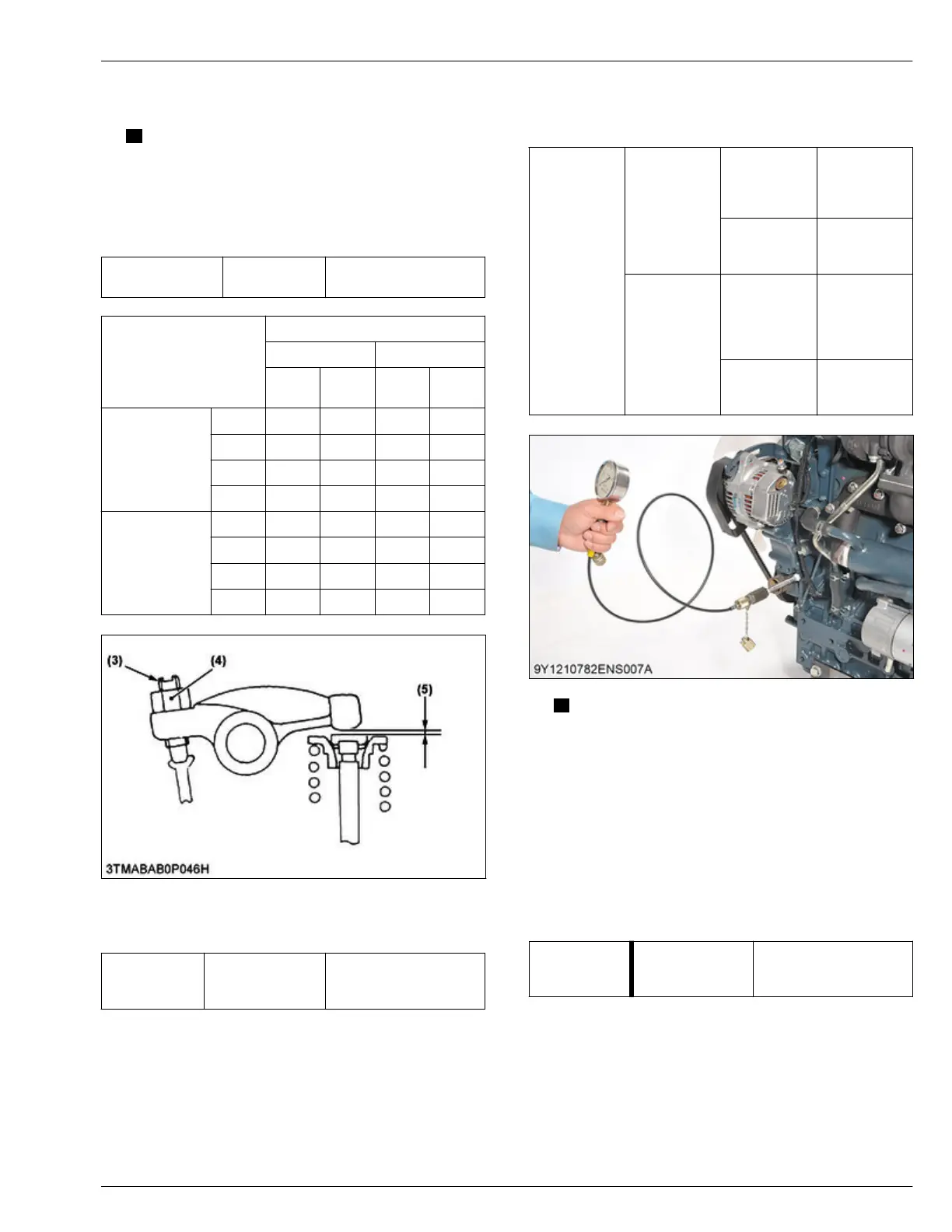

4.3 Checking engine oil pressure

Tools required

• Oil pressure tester

1.

Remove the engine oil pressure switch.

2. Set the oil pressure tester.

3. Operate the engine for warming-up.

4. Measure the

oil pressure at the idle speed and

rated speed.

Engine oil

pressure

At idle speed

Service speci-

fication

More than

98 kPa

1.0 kgf/cm

2

14 psi

Service limit

50 kPa

0.5 kgf/cm

2

7 psi

At rated

speed

Service speci-

fication

300 to

450 kPa

3.0 to

4.5 kgf/cm

2

43 to 64 psi

Service limit

250 kPa

2.5 kgf/cm

2

36 psi

NOTE

• If the

oil pressure is less than the service

limit, do a check below.

– Engine oil level

– Oil pump

– Oil strainer

– Oil filter cartridge

– Oil passage

– Oil clearance

– Relief valve

5. After checking the engine oil pressure, tighten its oil

pressure switch to the specified torque.

Tightening tor-

que

Oil pressure

switch

14.7 to 19.6 N⋅m

1.50 to 1.99 kgf⋅m

10.9 to 14.4 lbf⋅ft

SERVICING

4. Checking and adjusting 4. ENGINE

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...