5. Adjust

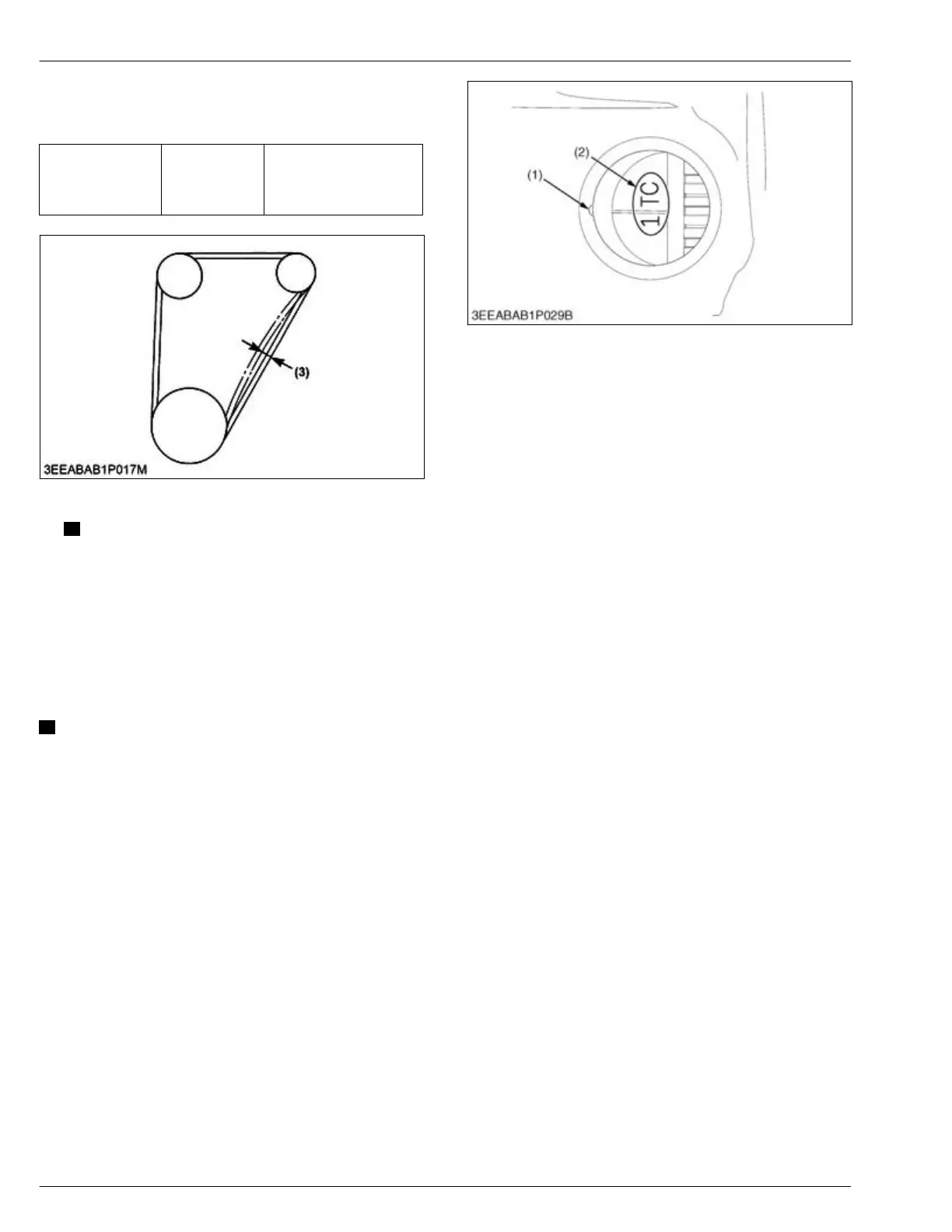

the tension of belt halfway between the fan

drive

pulley and alternator pulley at a specified

force to measure the deflection (3).

Deflection (3)

Service specifi-

cation

10.0 to 12.0 mm

0.394 to 0.472 in. in.

(under load of 98 N

(10 kgf, 22.1 lbf))

(3) Deflection

NOTE

• If the measurement is out of the service

specifications, loosen the alternator

mounting screws and adjust its position.

7. Check point of every 1000

hours

7.1 Checking valve clearance

IMPORTANT

• You must check and adjust the valve clearance

when the engine is cold.

Tools required

• Feeler gauge

1. Remove the air cleaner and muffler.

2. Remove the cylinder head cover

.

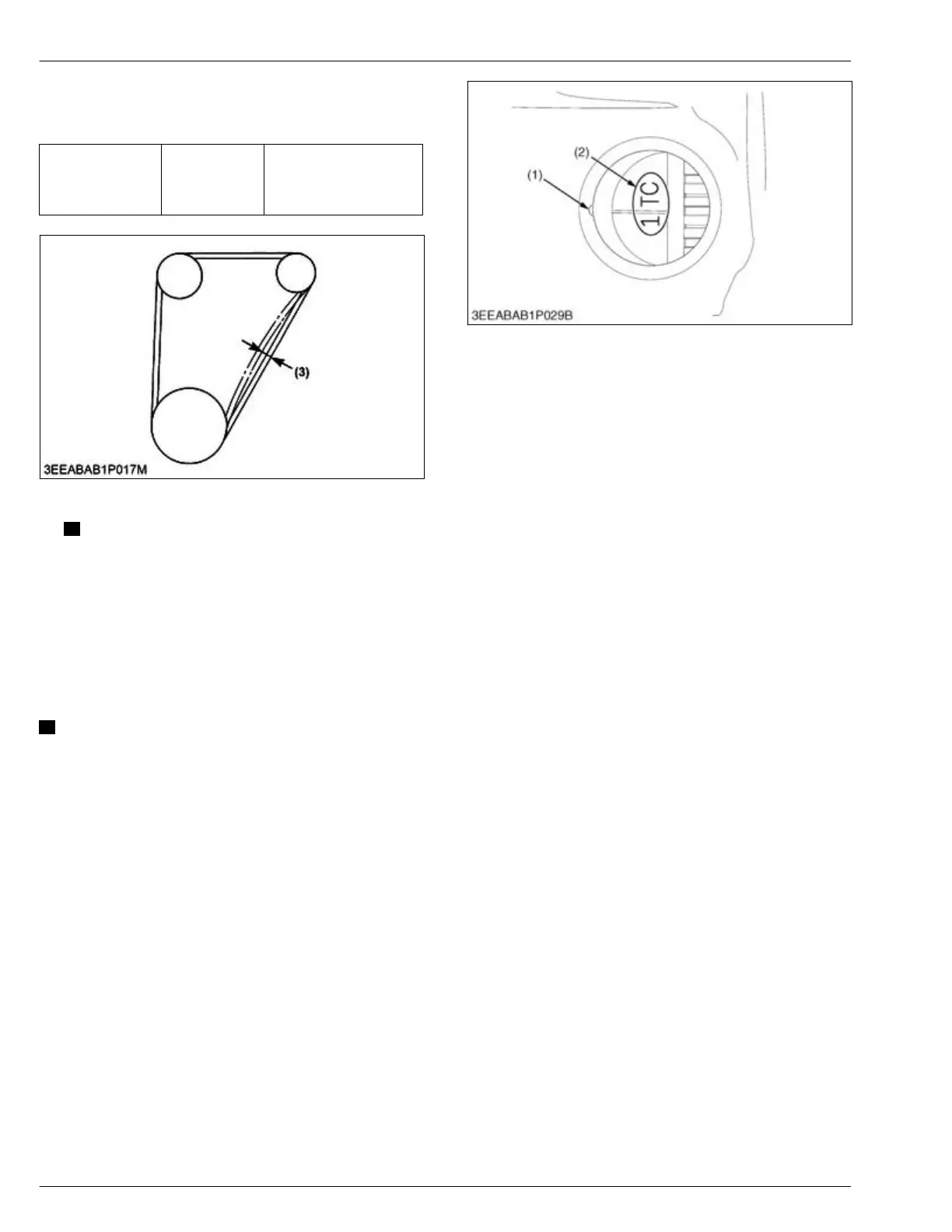

3. Align the [1TC] mark (2) line on the flywheel and

projection (1) on the housing.

4. Make sure that the No.1 piston comes to the

compression or overlap top dead center

.

3. MAINTENANCE

CHECK AND MAINTENANCE

7.Check point of every 1000 hours

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...