2FB/2FC-2.0

2-4-7

Periodic maintenance procedures

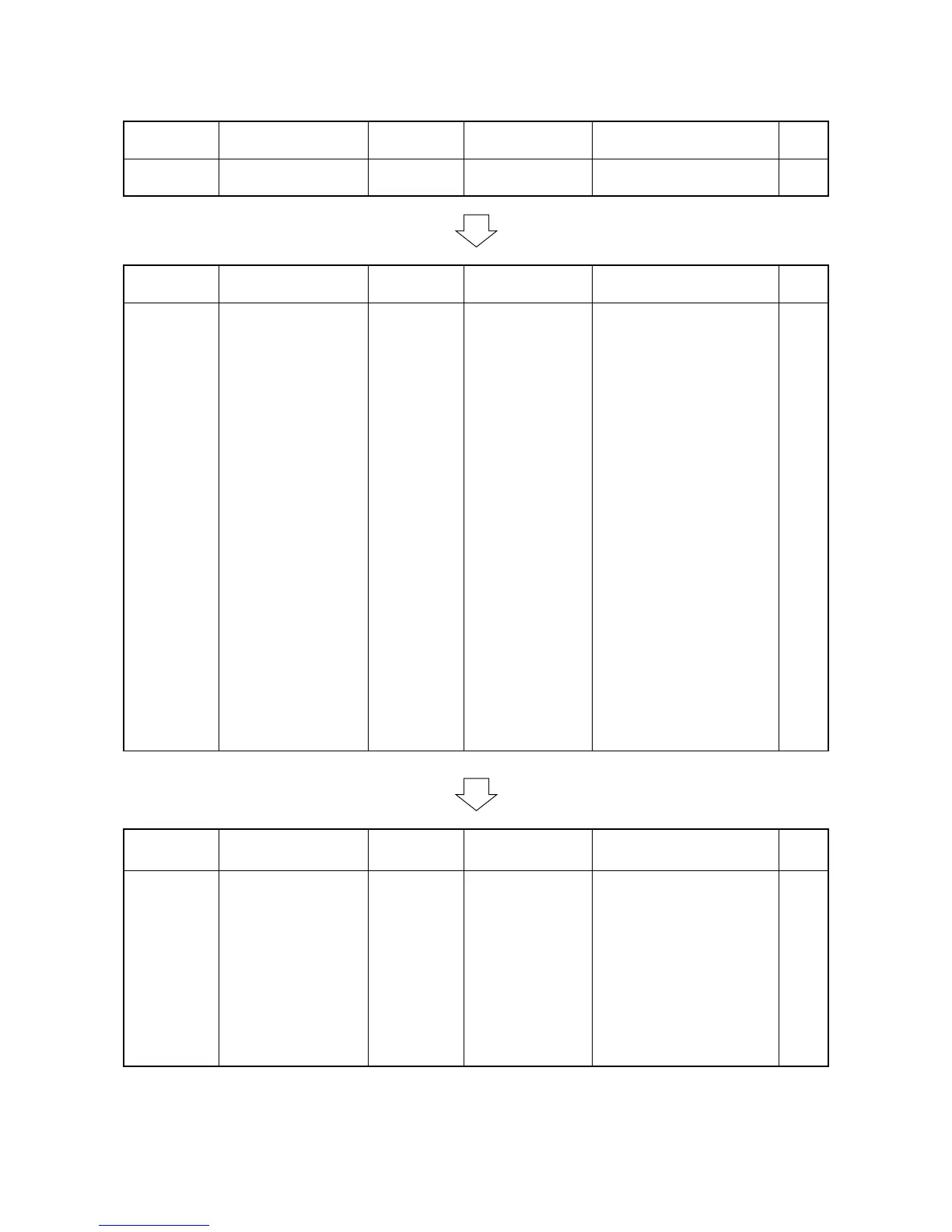

Section

Maintenance

part/location

Method

Maintenance cycle

Points and cautions Page

Test copy

and test print

Perform at the maxi-

mum copy size

Test copy Every service

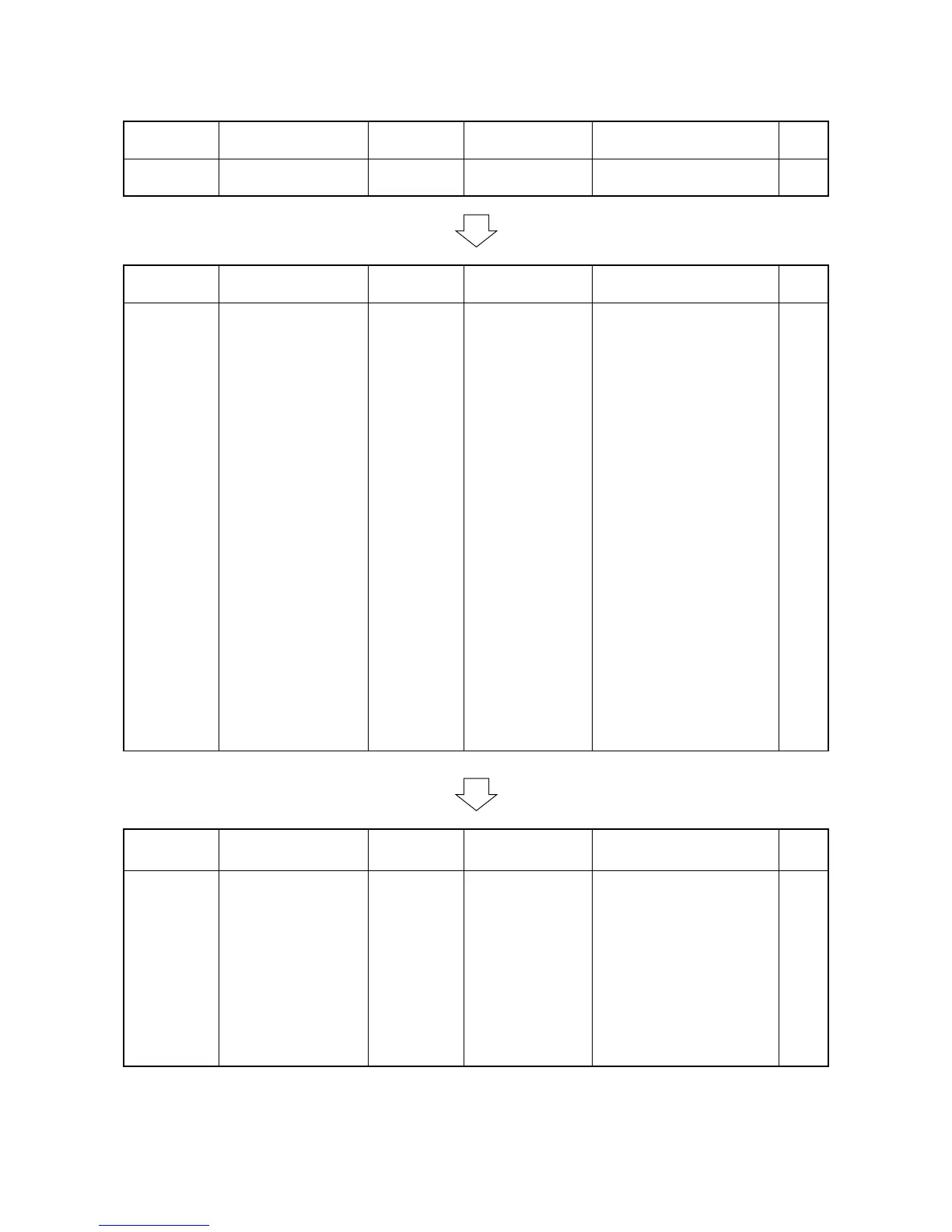

Section

Maintenance

part/location

Method

Maintenance cycle

Points and cautions Page

Paper feed

section

Paper feed pulleys Replace Every service Replace after feeding

500,000 sheets.

P. 1 -6 -3

P.1-6-10

Forwarding pulleys Replace Every service Replace after feeding

500,000 sheets.

P. 1 -6 -3

P.1-6-10

Separation pulleys Replace Every service Replace after feeding

500,000 sheets.

P. 1 -6 -3

P.1-6-10

MP paper feed pulley Clean

Check and

replace

Every service Clean with alcohol or a dry

cloth. Replace after feeding

250,000 sheets.

P.1-6-19

MP forwarding pulley Clean

Check and

replace

Every service Clean with alcohol or a dry

cloth. Replace after feeding

250,000 sheets.

P.1-6-19

MP separation pulley Clean

Check and

replace

Every service Clean with alcohol or a dry

cloth. Replace after feeding

250,000 sheets.

P.1-6-19

Timing switch 1 Clean Every service Air brush.

Timing switch 2 Clean Every service Air brush.

Timing switch 3 Clean Every service Air brush.

Feed pulley Clean Every service

Clean with alcohol or a dry cloth.

Deck conveying roller Clean Every service

Clean with alcohol or a dry cloth.

Rollers Clean Every service

Clean with alcohol or a dry cloth.

Guides Clean Every service

Clean with alcohol or a dry cloth.

Section

Maintenance

part/location

Method

Maintenance cycle

Points and cautions Page

Main charg-

ing section

Main charger unit

Clean

Check and

replace

Every service Clean the shield with a wet

cloth and then a dry cloth.

P.1-6-31

Main charger wire

cleaning pad

Replace

Every service

P.1-6-32

Main charger wire Replace

Every service

P.1-6-33

Main charger grid Clean

Check and

replace

Every service

Clean the shield with a wet

cloth and then a dry cloth.

Replace if the grid is damaged

or bending.

P.1-6-32

Loading...

Loading...