GENERAL INFORMATION

90-828631R3 MARCH 1999 Page 1C-9

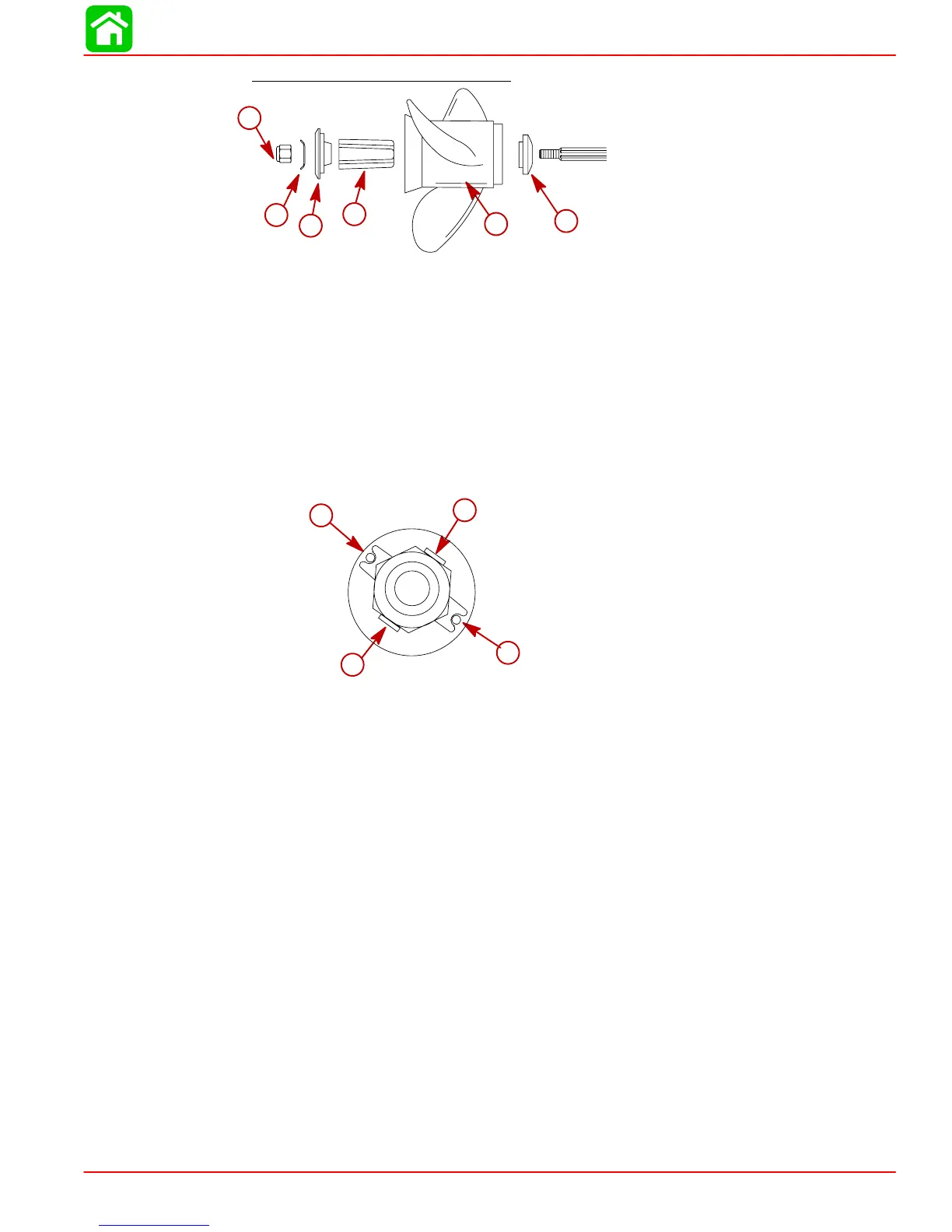

8. Flo-Torque II Drive Hub Propellers

e

d

c

b

a

f

a - Forward Thrust Hub

b - Propeller

c - Drive Sleeve

d - Rear Thrust Hub

e - Tab Washer

f - Propeller Nut

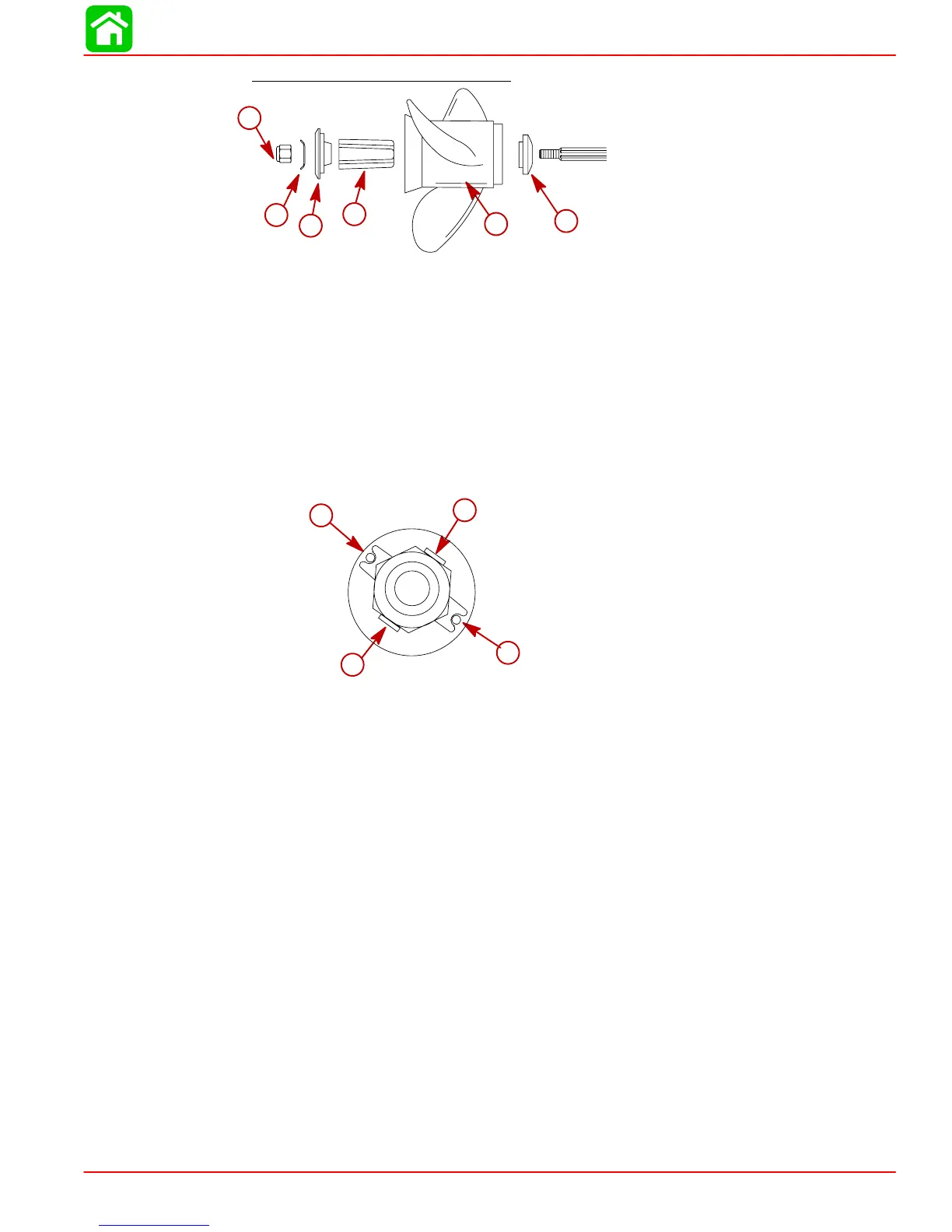

9. Place propeller nut retainer over pins. Place a block of wood between gear case and

propeller and tighten propeller nut to 55 lb-ft (75 Nm), aligning flat sides of the propeller

nut with tabs on the tab washer.

10. Secure propeller nut by bending tabs up and against the flats on the propeller nut.

a

a

b

b

a - Tab Washer Pins

b - Tabs

11. Reinstall spark plug leads.

Power Trim System

General Information

The power trim system is filled at the manufacturer and is ready for use.

Trim outboard through entire trim and tilt range several times to remove any air from the sys-

tem.

The trim system is pressurized and is not externally vented.

Power Trim Operation

With most boats, operating around the middle of the “trim” range will give satisfactory re-

sults. However, to take full advantage of the trimming capability there may be times when

you choose to trim your outboard all the way in or out. Along with an improvement in some

performance aspects comes a greater responsibility for the operator, and this is being aware

of some potential control hazards. The most significant control hazard is a pull or “torque”

that can be felt on the steering wheel or tiller handle. This steering torque results from the

outboard being trimmed so that the propeller shaft is not parallel to the water surface.

Loading...

Loading...