IGNITION

90-828631R3 MARCH 1999 Page 2A-13

Ignition Diagnostic Procedures

TROUBLESHOOTING TIP: With engine running, use inductive timing light to check spark

advance of each cylinder as throttle is opened and closed. If timing advances and retards

on each cylinder, ignition system is MOST LIKELY functioning properly.

IMPORTANT: If outboard appears to have an ignition system failure, it is recom-

mended that before beginning in-depth troubleshooting:

• Ensure that the engine is mechanically sound condition. (Fuel System, Cylinder Com-

pression etc.)

• Check all engine ground leads for loose or corroded connections.

• Disconnect and reconnect ignition harness connectors to verify proper continuity.

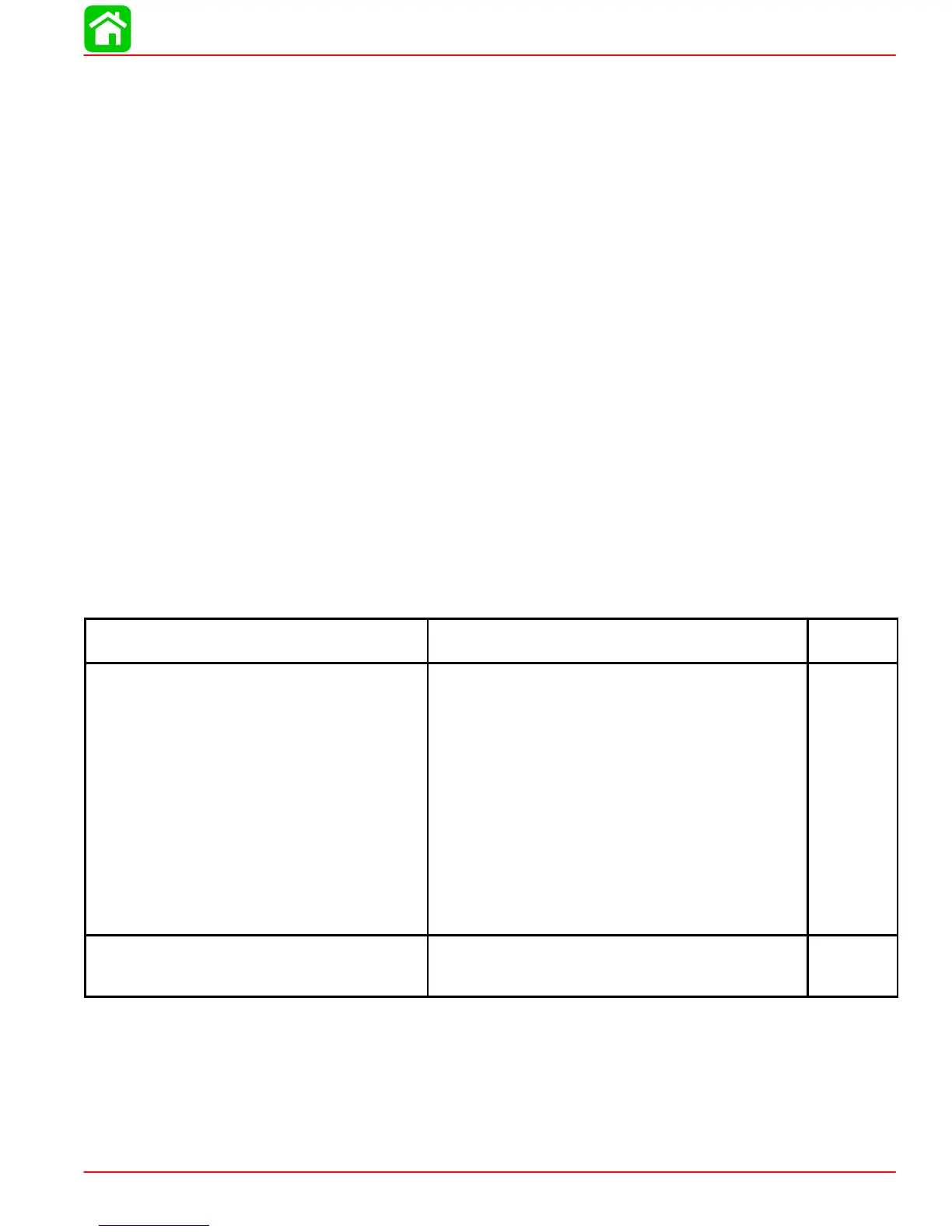

SUGGESTED TESTING PROCEDURES

NOTE: The following recommended tests and probable causes are not listed in any specific

order. The technician should use this table as a guide to help isolate and test the specific

problem/condition. Always perform the DVA tests first (if applicable), then perform resis-

tance test to validate suspected component failure.

*Recommended Test

(1) DVA TEST (Direct Voltage Adapter)

(2) OHM TEST (Resistance Testing)

(3) Replace Component and Retest

(4) Mechanical Test/Repair

PROBLEM/CONDITION

Probable Cause *Perform

Test No.

No Spark Condition (Both Cylinders) Trigger

Stator

(CDI) Unit

Stop Circuit Short to Ground:

a - stop circuit lead

b - lanyard stop switch

c - tiller handle stop button

d- remote control harness

Ignition Coil

Spark Plugs

Open Ground Condition:

a - ignition coil

b - (CDI) unit

c - stator ground

2

1-2

1-3

2

2

2

2

2

3

2

3

2

No Spark Condition (One Cylinder) High Tension Lead

Spark Plug Cap (Resistor)

Spark Plug

2

2

3

Loading...

Loading...