BIGFOOT GEAR HOUSING

90-828631R3 MARCH 1999 Page 6B-57

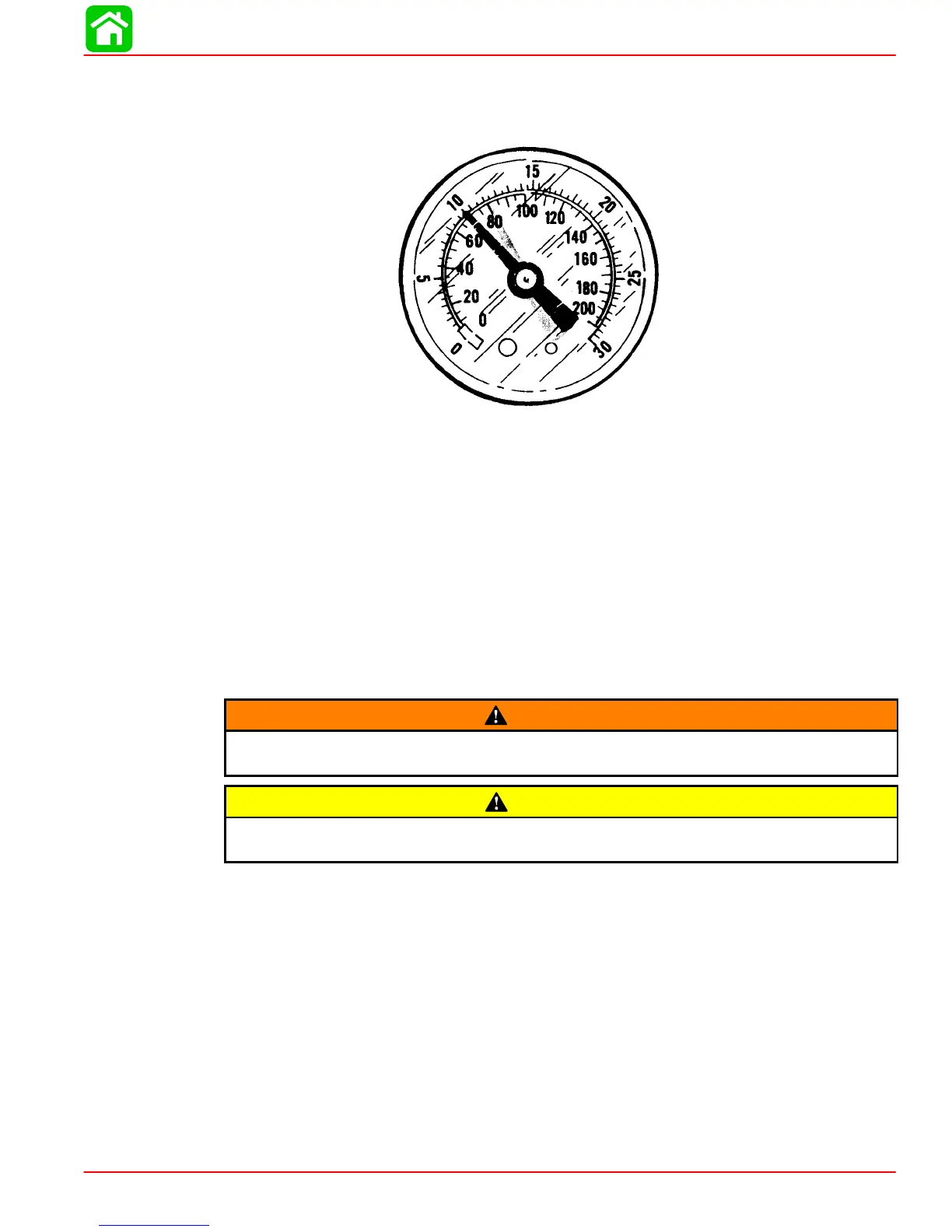

2. Pressurized housing to 10 to 12 psi

(69-83 kPa)

and observe gauge for 5 minutes.

3. Rotate driveshaft, prop shaft and move shift shaft while housing is pressurized to check

for leaks.

4. If pressure drop is noted, immerse housing in water.

5. Re-pressurize to 10 to 12 psi

(69-83 kPa)

and check for air bubbles.

6. Replace leaking seals as necessary. Retest housing.

NOTE: Gearcase should hold 10 to 12 psi (69-83 kPa) for 5 minutes.

7. Remove tester from housing and install vent plug.

Filling Gear Housing With Lubricant

NOTE: Gear housing lubricant capacity is 22.5 fl oz (665.2 ml).

WARNING

If gear housing is installed on engine, to avoid accidental starting, disconnect (and

isolate) spark plug leads from spark plugs before working near the propeller.

CAUTION

Do not use automotive grease in the gear housing. Use only Quicksilver Gear Lube

or Quicksilver Super-Duty Lower Unit Lubricant.

1. Remove any gasket material from “Fill” and “Vent” screws and gear housing.

2. Install new gaskets on “Fill” and “Vent” screws.

IMPORTANT: Never apply lubricant to gear housing without first removing “Vent”

screws or gear housing cannot be filled because of trapped air. Fill gear housing only

when housing is in a vertical position.

3. Remove lubricant “Fill” screw and gasket from gear housing.

4. Insert lubricant tube into “Fill” hole, then remove “Vent” screws and gaskets.

5. Fill gear housing with lubricant until excess starts to flow out of one (first) “Vent” screw

hole.

Loading...

Loading...