4-42 - POWERHEAD 90-830234R3 DECEMBER 1997

Check Valves

REMOVAL

• Remove carburetors and intake manifold/reed

block assemblies.

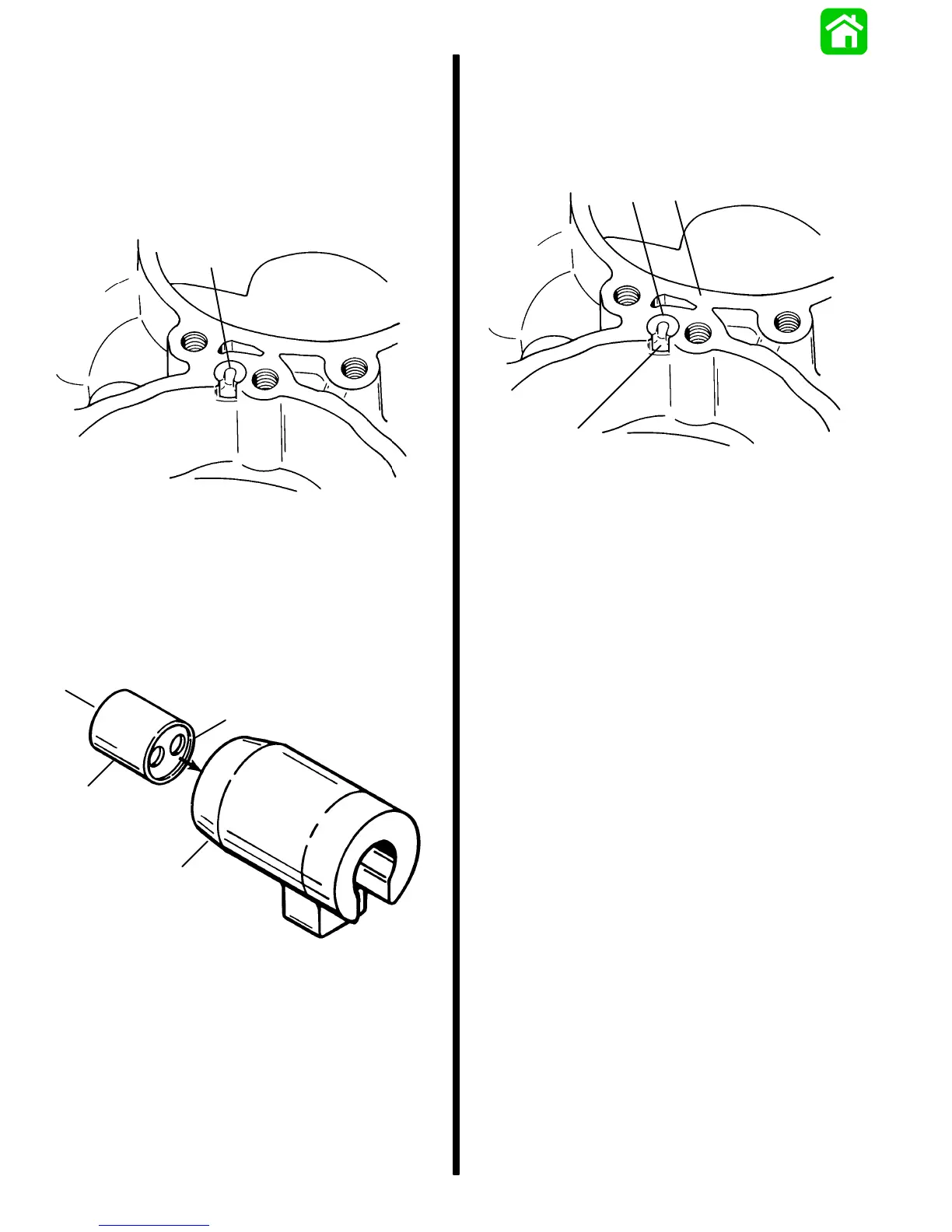

• Grasp carrier and remove carrier/check valve as-

sembly from crankcase cover.

a

51621

a - Carrier/Check Valve Assembly

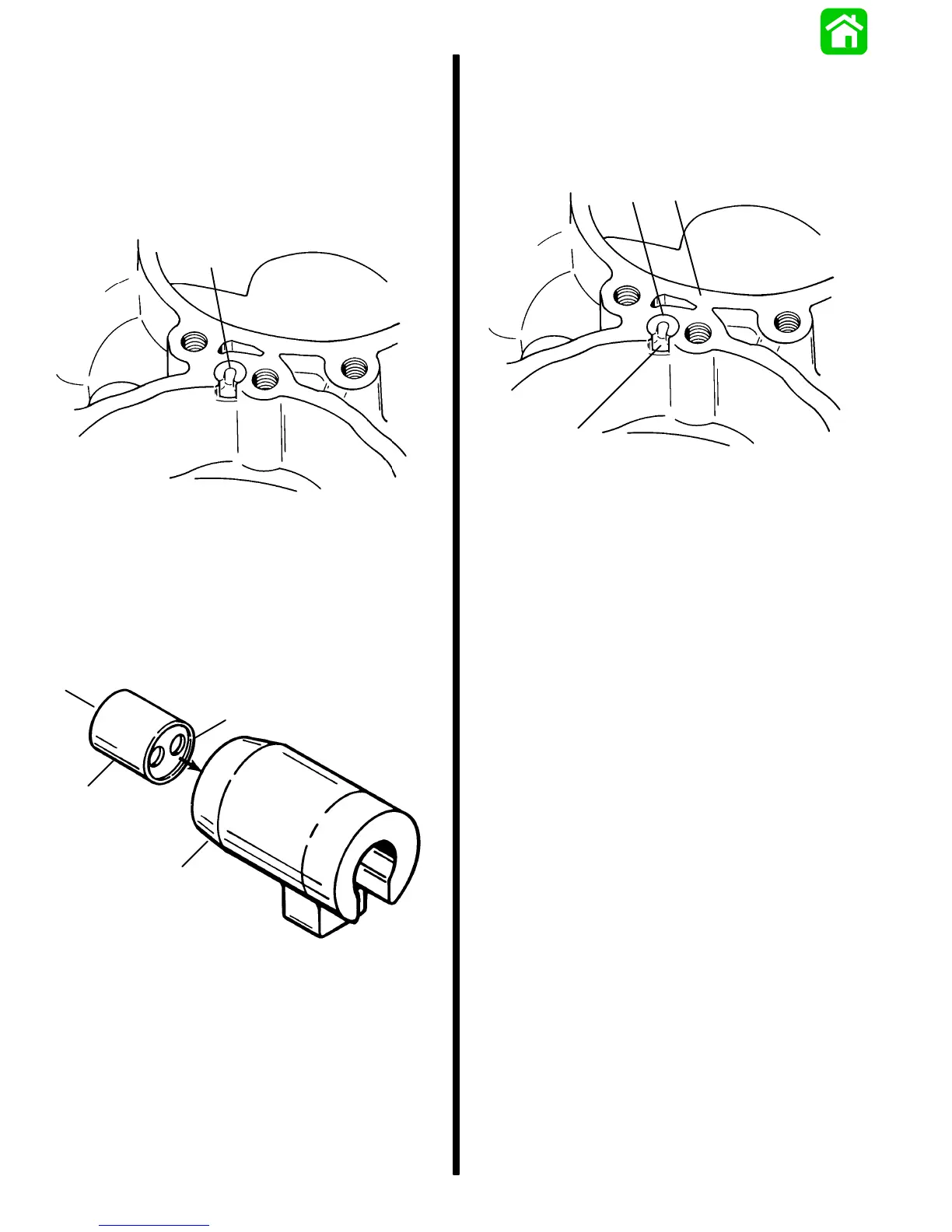

• Push check valve out of carrier. If nylon ball within

check valve is stuck or carrier is charred, replace

check valve and/or carrier as required.

IMPORTANT: SINGLE HOLE side of check valve

MUST FACE CRANKCASE.

b

a

d

c

51131

a - Check Valve

b - Carrier

c - Single Hole

d - Double Hole

INSTALLATION

• Install check valve (if removed) inside of carrier

(single hole of valve faces tapered end of carrier).

• Align carrier tab with slot in crankcase cover and

insert check valve/carrier assembly into cover.

a

b

c

51621

a - Check Valve/Carrier Assembly

b - Slot

c - Crankcase Cover

• Clean mating surfaces of crankcase cover and

intake manifold. Install new gaskets.

• Install intake manifold/reed block assemblies to

crankcase cover. Refer to PAGE 4-58 for torque

specification and tightening sequence.

• Install carburetors. Torque carburetor (AIR BOX)

stud nuts to 100 lb. in. (11.3 Nm).

• Carburetors MUST BE SYNCHRONIZED. Refer

to SECTION 2C for proper procedures.

• Reinstall air box cover.

• Reinstall top cowling.

Piston and Piston Rings

IMPORTANT: If engine was submerged while en-

gine was running, piston pin and connecting rod

may be bent. If piston pin is bent, piston must be

replaced. Piston pins are not sold separately be-

cause of matched fit into piston. If piston pin is

bent, connecting rod must be checked for

straightness (refer to “Connecting Rods” for

checking straightness).

• Inspect piston for scoring and excessive piston

skirt wear.

Loading...

Loading...