90-830234R3 DECEMBER 1997 POWERHEAD - 4-47

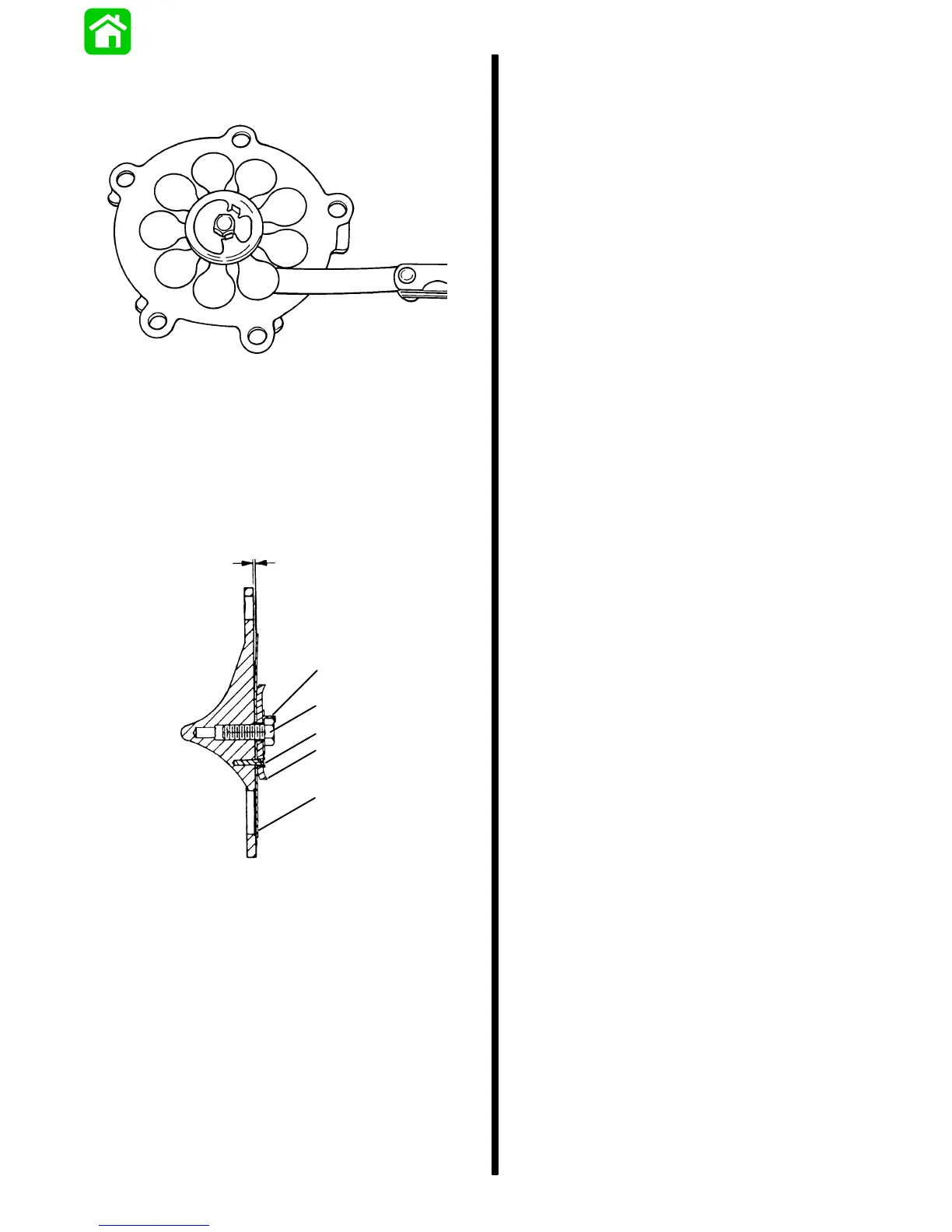

If the opening exceeds 0.020 in. (0.51mm), or if the

reed is chipped, cracked, or otherwise damaged, re-

place.

19337

Replace locking tab-washer. DO NOT REUSE.

If reed block was disassembled, reassemble by lo-

cating reeds on pins with retaining washer. Use new

tab washer. Insert bolt, and torque to 80 lb. in. (9.0

Nm); then, if necessary, continue the torque to align

flat on hex-head to locking tab - Do not exceed 100

lb. in. (11.3 Nm) torque. Bend up tab to secure bolt

position.

a

b

c

d

e

0.020 MAX.

a - Reeds

b - Retaining Washer

c - Pins

d - Bolt

e - Locking Tab

Powerhead Reassembly and

Installation

General Information

Before proceeding with powerhead reassembly, be

sure that all parts to be reused have been carefully

cleaned and thoroughly inspected, as outlined in

“Cleaning and Inspection”. Parts, which have not

been properly cleaned (or which are questionable),

can severely damage an otherwise perfectly good

powerhead within a few minutes of operation. All new

powerhead gaskets must be installed during

assembly.

During reassembly, lubricate parts with Quicksilver

2-Cycle Outboard Oil whenever 2-cycle oil is speci-

fied and Quicksilver 2-4-C w/Teflon whenever grease

is specified.

A torque wrench is essential for correct reassembly

of powerhead. Do not attempt to reassemble power-

head without using a torque wrench.

EXAMPLE: If Exhaust Cover bolts require a torque of

220 lb. in. (24.9 Nm), a) tighten all bolts to 73 lb. in.

(8.2 Nm), following specified torque sequence, b)

tighten all bolts to 146 lb. in. (16.5 Nm), following

torque sequence, then finally, c) tighten all bolts to

220 lb. in. (24.9 Nm), following torque sequence.

Loading...

Loading...