90-830234R3 DECEMBER 1997 ATTACHMENTS/CONTROL LINKAGE - 7A-27

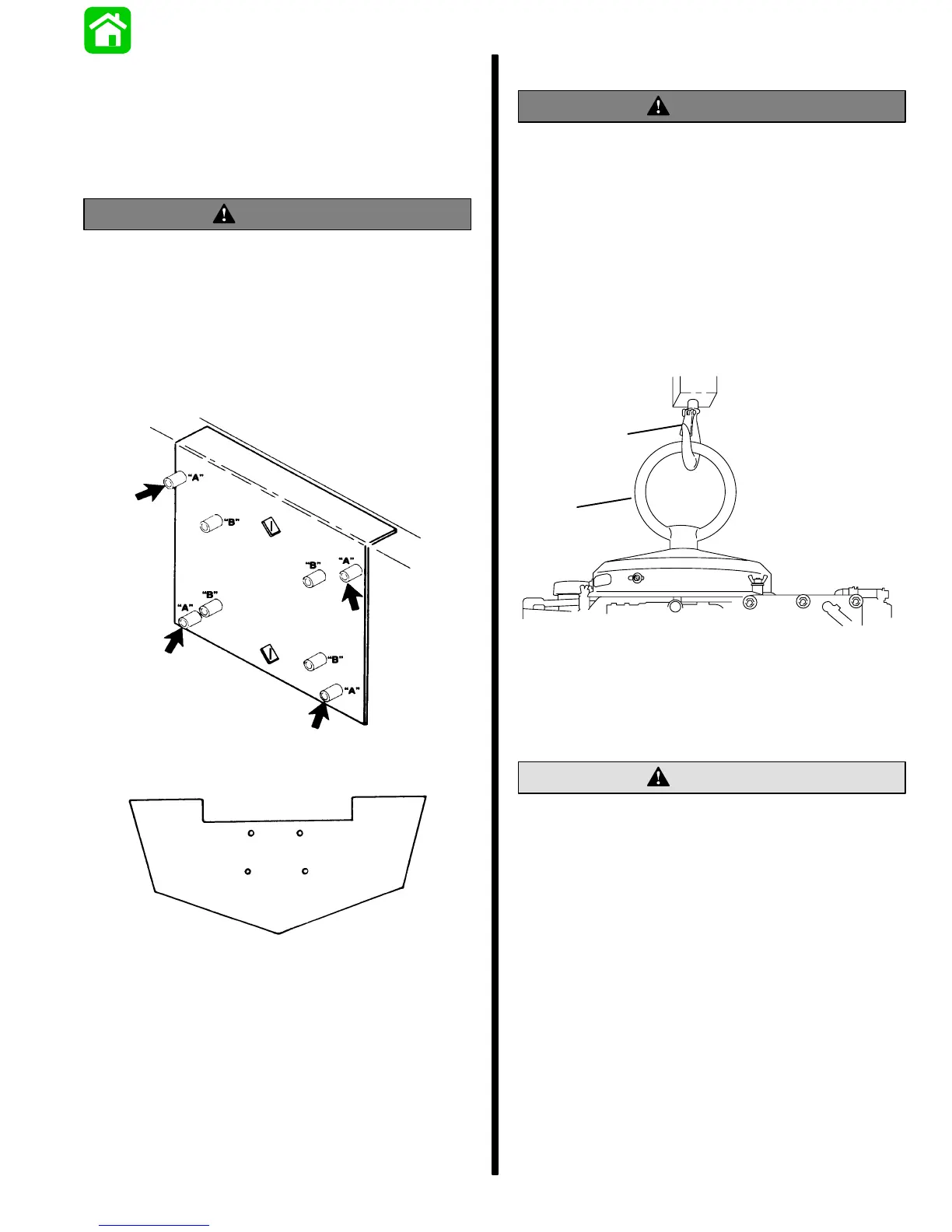

Drilling Outboard Mounting Holes

IMPORTANT: Before drilling any mounting holes,

carefully read “Determining Recommended Out-

board Motor Mounting Height”, preceding. There

is a 3/4 in. (19mm) difference between outboard

mounting holes in transom bracket.

WARNING

DO NOT, under any circumstances, allow upper

outboard mounting bolts to be closer than 1 in.

(25.4mm) from top of boat transom. Upper

mounting bolts must never be installed thru

shims.

IMPORTANT: If using “Transom Drill Fixture”

(91-98234A2), use drill guide holes marked “A”

when drilling outboard mounting holes.

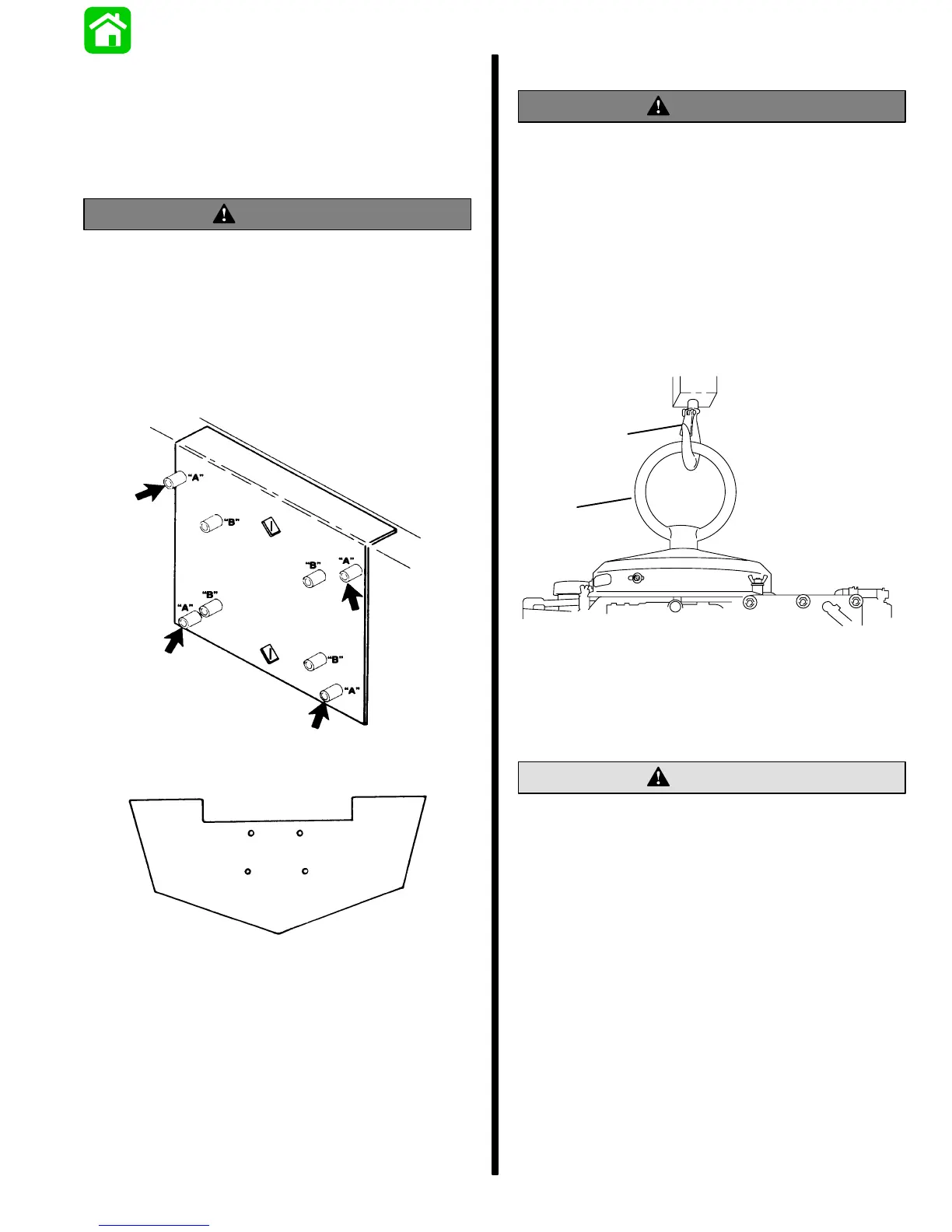

Lifting Engine

WARNING

Make sure that lifting eye is threaded into fly-

wheel a minimum of 5 turns and that hoist has a

minimum lift capacity of at least 500 lbs. (227 kg)

BEFORE lifting engine.

1. Remove cowling from engine and plastic cap

from center of flywheel. Thread lifting eye into fly-

wheel hub a minimum of 5 turns. Replace plastic

cap after installation.

2. Connect hoist [minimum lift capacity of 500 lbs.

(227 kg)] to lifting eye. Lift engine and place on

boat transom.

b

a

25929

a - Lifting Eye (C-91-75132)

b - Hoist

Installing Engine to Transom

CAUTION

Marine sealer must be used on shanks of mount-

ing bolts to make a water-tight installation.

NOTE: Because of clearance on some boats it will be

necessary to install steering cable on engine before

installing engine to transom. Refer to page 1 of this

instruction.

IMPORTANT: DO NOT use an impact driver when

tightening transom mounting bolts.

1. Determine engine mounting height dimension

from graph (STEP 1) and use engine mounting

holes that will position engine nearest to recom-

mended height.

Loading...

Loading...