F

THE

GEARBOX.------------------

Extract

the

split pin from

the

nut retaining

the

drive

flange at

the

rear

of

the

gearbox sliding shaft and

remove

the

nut and plain washer.

Remove

the

six nuts securing

the

top

cover assembly

to

the

gearbox and

the

four

bolts and spring washers

securing

the

remote

control cover assembly

to

the

gearbox

extension.

Remove

the

three

selector

springs.

USing

the

extractor,

Tool No. T.IOS (Section Q).

withdraw

the

propeller shaft driving flange. It is

advisable

to

use an

extractor

of this

type

to

avoid

Fig. F.2.

A plug

threaded

into

the

drain plug hole is used

to

hold

the

gearbox

in

the

vl"e.

distortion of

the

flange face. Before doing so, it is

advisable

to

mark both

the

flange and

the

shaft so

that

they

can be replaced in exactly

the

same position.

Detach

the

speedometer

drive housing from

the

right-hand side of

the

gearbox.

Care

should be

exercised

not

to damage

the

paper

gasket on tile Joint

face of

the

housing.

Extract

the

lock-wire from

the

eight square-headed

screws locking

the

gear shifters and stops

to

the

selector shafts and remove

the

screws.

Slacken

the

nuts and

set

bolts securing

the

gearbox

rear

casing to

the

gearbox and withd raw sufficiently

to

allow

the

gear shifters

to

be removed from

the

ends

of

the

selector shafts.

Remove

the

nuts and

set

bolts completely and with-

draw

the

gearbox rear casing from

the

gearbox.

On early type gearboxes withdraw

the

selector

shafts 0 ne at a ti me, takl ng care not

to

lose

the

se

lector

lock balls in

the

process. Later models have a third

and

top

selector shaft

extended

at Its front end and

fitted with a clrcllp

to

prevent

its accidental wlth-

F.2

drawal and

the

loss of

the

synchromesh balls. In this

case

the

cirelip must, of course. be removed before

the

shaft can be withdrawn. This also makes It

imperative to remove

the

gearbox from

the

engine

before dismantling.

Now

lift

out

the

selector forks.

Referen ce to page E.IO will show

the

interlocklng

mechanism of

the

shifter balls. Observe

the

correct

position of

the

gear shifters and stops on

the

selector

spindles as shown in

the

plan view of

the

shifters and

shafts.

Remove

the

layshaft spindle locating screw from

the

rear of

the

gearbox.

Extract

the

layshaft spindle by tappl ng it at

the

forward end with a suitable copper

or

brass drift.

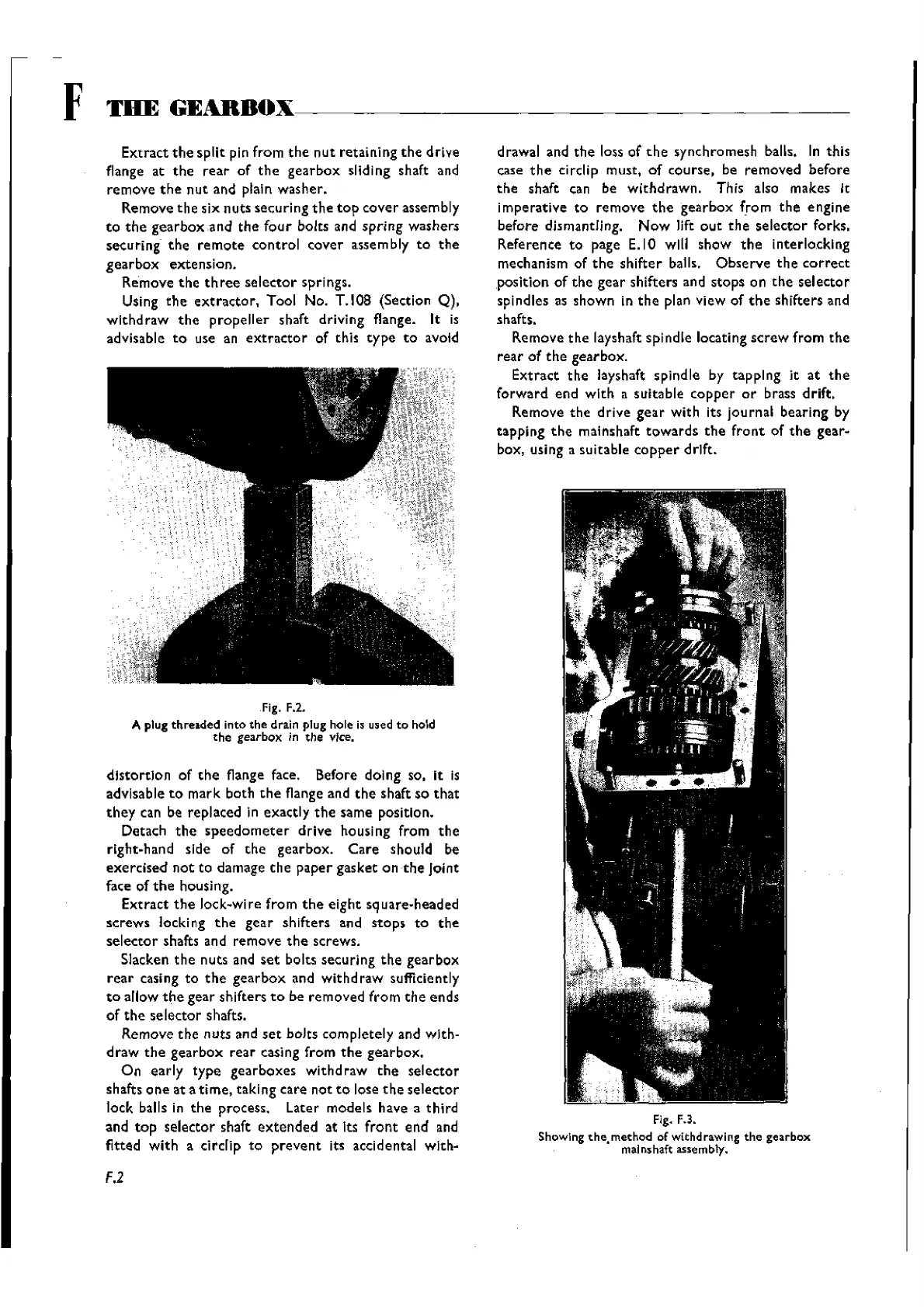

Remove

the

drive gear with its journal bearing by

tapping

the

malnshalt

towards

the

front

of

the

gear-

box, using a suitable

copper

drift.

Fig. F.3.

Showing

the.

method of withdrawing

the

gearbox

malnshaft assembly.

Wishvilles Classic

Automobile Library

Loading...

Loading...