G

TIlE

PROPELIJER

SIIAF"'r-----------

Section

G.7

REPLACEMENT

OF THE

PR.OPELLER

SHAFT

Wipe

the

faces of

the

flanges clean, and place

the

propeller

shaft In position on

the

car. Ensure

that

A

the

flange registers engage correctly and

that

the

joint faces bed down evenly all round. also

that

the

markings. made on

the

flanges on removal. coincide.

Insert

the

bolts and see

that

all th e nuts. wh lch

are

of

the

self-locking type. are evenly and securely

tightened. The sliding Joint is always placed at

the

gearbox

end.

B

D

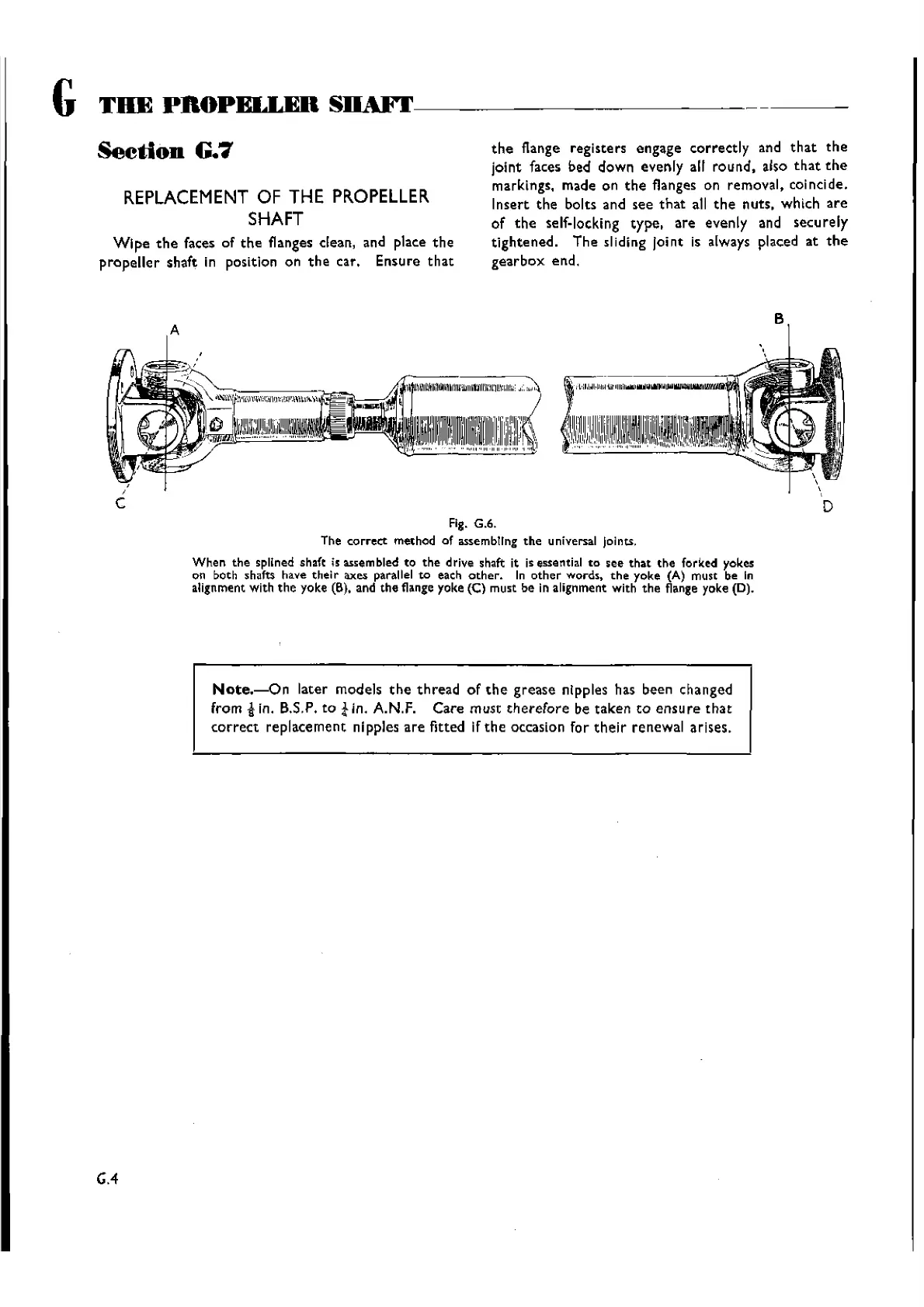

Fig. G.6.

The

correct

method of assembtrng

the

universal Joints.

When

the

spllned shaft is assem bled to

the

drive shaft it is essential

to

see

that

the

forked yokes

on both shafts have

their

axes parallel

to

each

other.

In

other

words.

the

yoke (A) must be In

alignment with

the

yoke (6), and

the

flange yoke (C) must be in alignment with

the

flange yoke (D).

Note.-On

later models

the

thread

of

the

grease nipples has been changed

from .gIn. B.S.P. to

tin.

A.N.F.

Care

must

therefore

be taken

to

ensure

that

correct

re pIacement nipples

are

fitted if th e occasion for th eIr re newal arises.

GA

Wishvilles Classic

Automobile Library

Loading...

Loading...