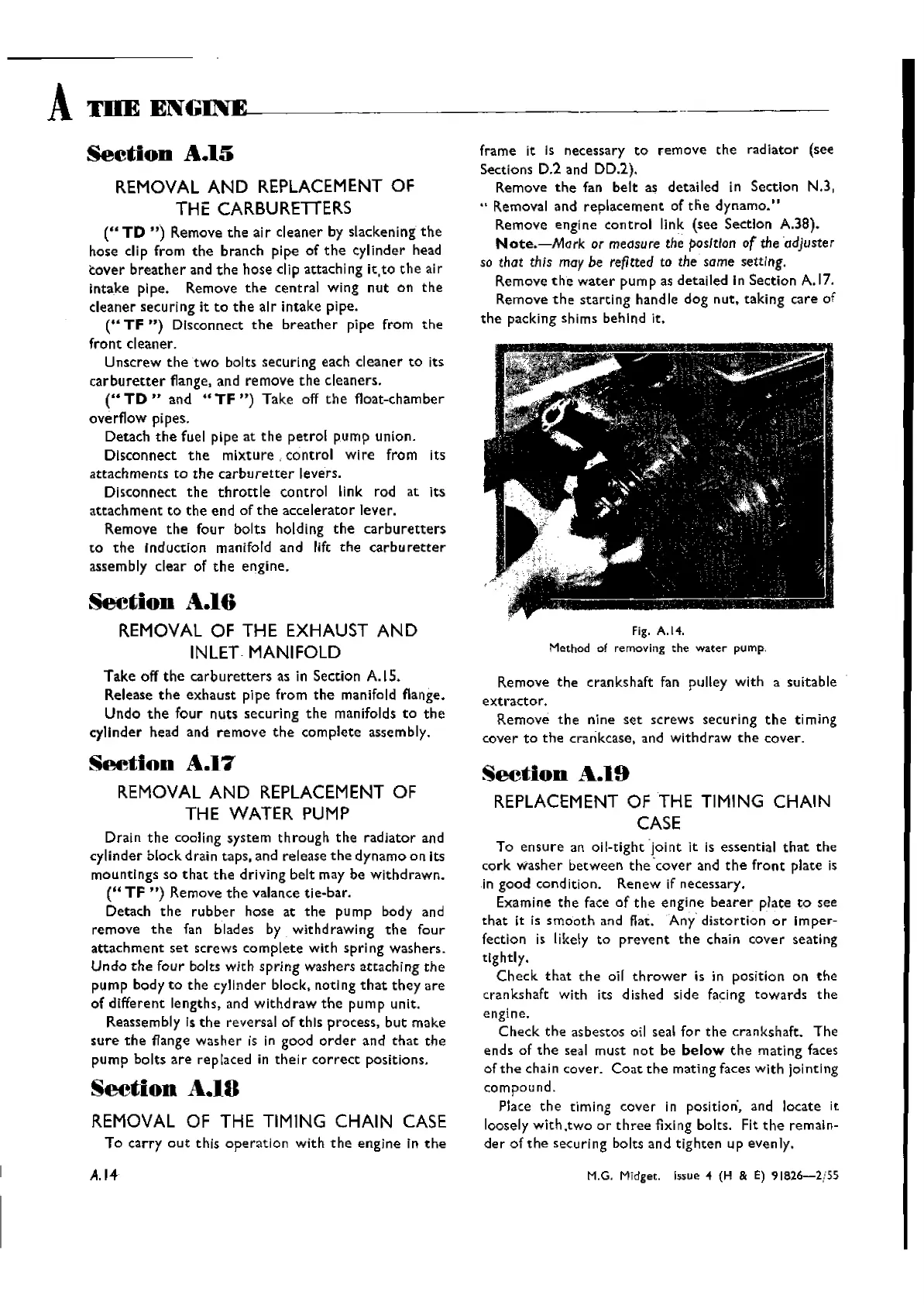

Fig. A.14.

Method of removing the

water

pump.

Remove

the

crankshaft fan pulley with a suitable

extractor.

Remove

the

nine

set

screws securing

the

timing

cover

to

the

crankcase, and withdraw

the

cover.

frame it Is necessary

to

remove

the radiator (see

Sections D.2 and DD.2).

Remove

the

fan

belt

as detailed in Section N.3,

.. Removal and

replacement

of

tne

dynamo."

Remove engine

control

link (see Section A.38).

Note.-Mark

or

measure

the positIon

of

the 'adjuster

so that this may be refitted to the same setting.

Remove t he

water

pump as detailed in Section

A.17.

Remove

the

starting

handle dog nut, taking care of

the

packing shims behind it.

section

A.l6

REMOVAL OF THE EXHAUST

AND

INLET- MANIFOLD

Take off

the

carbu

retters

as in Section A.IS.

Release

the

exhaust

pipe from

the

manifold flange.

Undo

the

four

nuts

securing

the

manifolds

to

the

cylinder head and

remove

the

complete assembly.

A

mE

ENGINE~----------,--

Section

A.15

REMOVAL

AND

REPLACEMENT OF

THE CARBURETTERS

(U

TO

")

Remove

the

air

cleaner by slackening

the

hose clip from

the

branch pipe of

the

cylinder head

cover

breather

and

the

hose clip attaching

it,to

the

air

intake pipe. Remove

the

central wing

nut

on

the

cleaner securing it

to

the

air intake pipe.

(.. TF

")

Dlsconnect

the

breather

pipe from

the

front

cleaner.

Unscrew

the

two

bolts securing each

cleaner

to

its

carburetter

flange, and remove

the

cleaners.

(U

TO

.. and ..

TF

")

Take off

the

float-chamber

overflow pipes.

Detach

the

fuel pipe at

the

petrol

pump union.

Disconnect

the

mixture,

control

wire

from its

attachments

to

the

carburetrer

levers.

Disconnect

the

throttle

control link rod at its

attachment

to

the

end of

the

accelerator

lever.

Remove

the

four

bolts holding

the

carburetters

to

the

Induction manifold and lift

the

carburetter

assembly clear of

the

engine.

Seetion

A.17

REMOVAL

AND

REPLACEMENT OF

THE WATER PUMP

Drain

the

cooling system

through

the

radiator

and

cylinder block drain taps, and release

the

dynamo on its

mountings so

that

the

driving belt may be Withdrawn.

(U

TF

")

Remove

the

valance tie-bar.

Detach

the

rubber

hose at

the

pump body and

remove

the

fan blades by withdrawing

the

four

attachment

set

screws

complete

with

spring

washers.

Undo

the

four bolts with

spring

washers attaching

the

pump body

to

the

cylinder block, noting

that

they

are

of different lengths, and

withdraw

the

pump unit.

Reassembly [s

the

reversal of this process,

but

make

sure

the

flange washer is in good

order

and

that

the

pump

bolts

are

replaced in

their

correct

positions.

Section

A.lO

REMOVAL OF THE TIMING

CHAIN

CASE

To carry

out

this

operation

with

the

engine in

the

A.14

Section

...

"-.19

REPLACEMENT OF THE TIMING

CHAIN

CASE

To

ensure

an oil-tight -joint it is essential

that

the

cork

washer

between

the

'cover

and

the

front

plate is

in good condition. Renew if necessary.

Examine

the

face of

the

engine

bearer

plate

to

see

that

it is

smooth

and flat. Any' distortion

or

1m

per-

fection is likely to

prevent

the

chain

COver

seating

tightly.

Check

that

the

oil

thrower

is in position on

the

crankshaft With its dished side facing

towards

the

engine.

Check

the

asbestos oil seal

for

the

crankshaft. The

ends of

the

seal must not be

below

the

mating faces

of

the

chain cover.

Coat

the

mating faces with jointing

compound.

Place

the

timing cover in position', and locate it

loosely

with.two

or

three

fixing bolts. Fit

the

remain-

der

of

the

securing bolts and tighten up evenly.

M.G. Midget. Issue 4 (H & E)

91826-2/55

Wishvilles Classic

Automobile Library

Loading...

Loading...