-----

---------

TIlE

ENGINE

A

Remove

the

valve

cover

and

rocker

gear

from

the

cylinder

head as indicated in Section A.B,

when

the

push-rods

may be withdrawn.

Note.-It

is advisable to keep these in order

of

f'emoval.

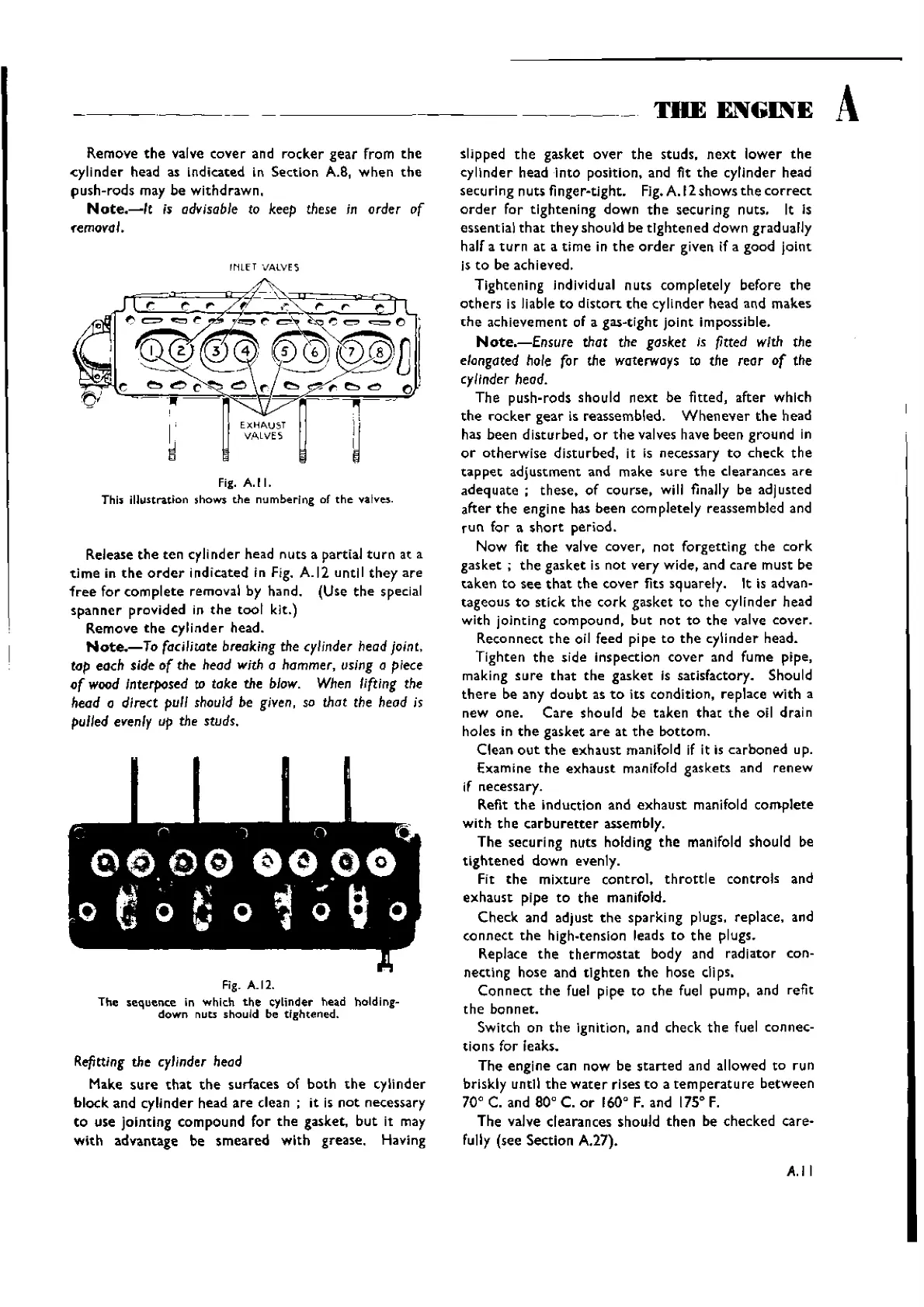

INlET

VALVES

Fig.

A.II.

This illustration shows

the

numbering of

the

valves.

Release

the

ten

cylinder head nuts a partial tu rn at a

ti

me in

the

order

indicated in Fig. A.

12

until

they

are

free

for

complete

removal by hand. (Use

the

special

spanner

provided

in

the

tool

kit.)

Remove

the

cylinder head.

Note.-To

facilitate breaking the cylinder head joint,

tap each side

of

the head with a hammer, using a piece

of

wood Interposed to take the blow. When lifting the

head a

direct pull

should

be given, so that the head is

pulled evenly up the studs.

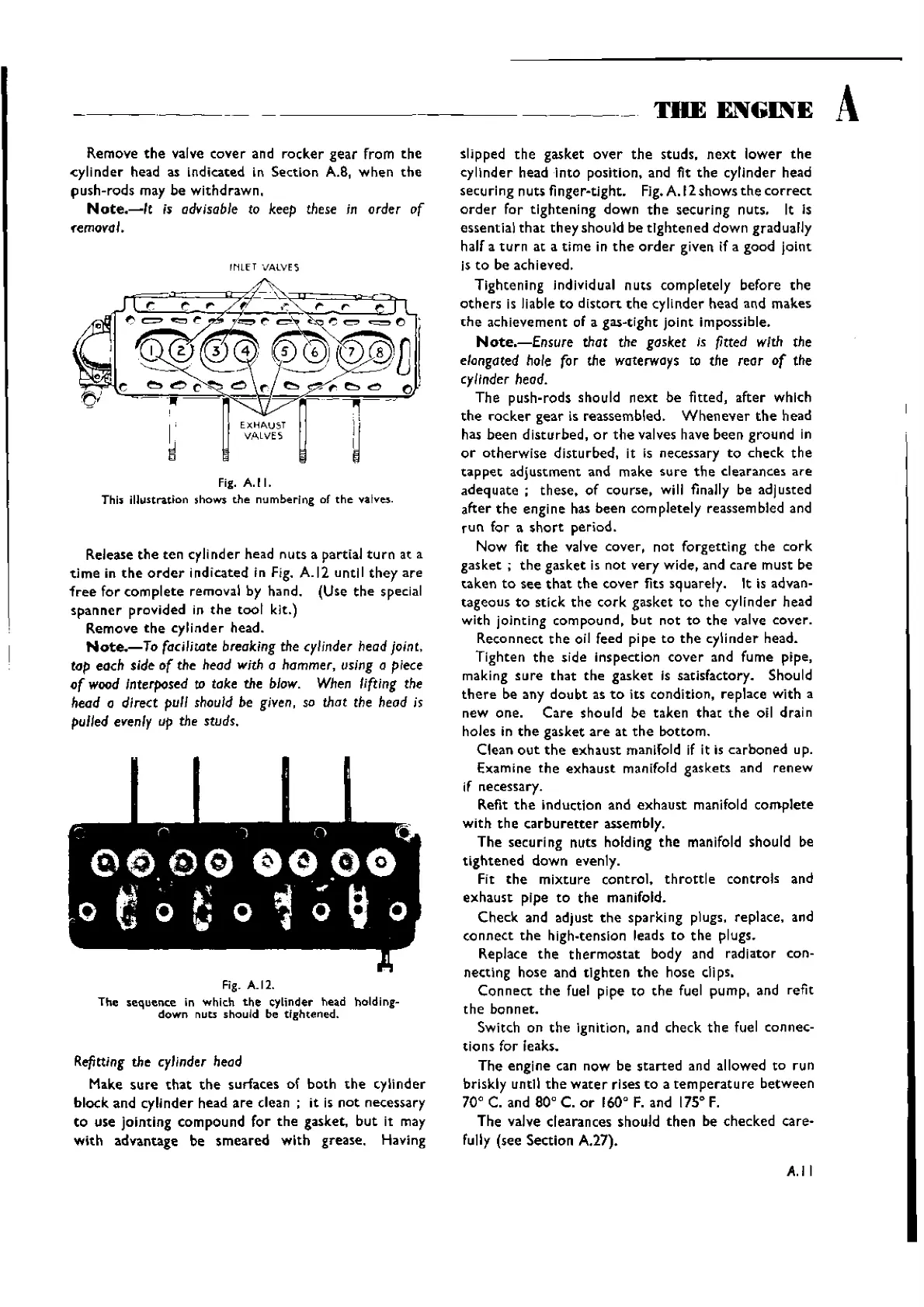

Fig. A.12.

The sequence in which

the

cylinder head holding-

down

nuts should be tightened.

Refitting the cylinder head

Make

sure

that

the

surfaces of both

the

cylinder

block

and cylinder head

are

clean;

it is

not

necessary

to

use jointing compound for

the

gasket,

but

it may

with

advantage be

smeared

with

grease. Having

slipped

the

gasket

over

the

studs,

next

lower

the

cylinder head

into

position, and fit

the

cylinder head

secu ring

nuts f nger-tight. Fig.A.12 shows

the

correct

order

for tightening down

the

securing nuts. It Is

essential

that

they should be

tightened

down gradually

half a

turn

at

a time in

the

order

given if a good

joint

is

to

be achieved.

Tightening individual nuts completely before

the

others

is liable

to

distort

the

cylinder head and makes

the

achievement of a gas-tight

joint

impossible.

Note.-£nsure

that the gasket is fitted with the

elongated hole for the waterways to the reor

of

the

cylinder head.

The push-rods should

next

be fitted, after which

the

rocker

gear is reassembled.

Whenever

the

head

has been

disturbed,

or

the

valves have been ground in

or

otherwise

disturbed, it is necessary

to

check

the

tappet

adjustment

and make

sure

the

clearances

are

adequate;

these.

of

course, will finally be ad]usted

after

the

engine has been completely reassembled and

run

for a

short

period.

Now fit

the

valve cover, not forgetting

the

cork

gasket;

the

gasket is not very wide, and care must be

taken

to

see

that

the

cover

fits squarely. It is advan-

tageous

to

stick

the

cork

gasket to

the

cylinder head

with jointing compound,

but

not

to

the

valve cover.

Reconnect

the

oil feed pipe

to

the

cylinder head.

Tighten

the

side inspection

cover

and fume pipe,

making

sure

that

the

gasket is satisfactory. Should

there

be any

doubt

as

to

its condition, replace with a

new one.

Care

should be taken

that

the

oil drain

holes in

the

gasket

are

at

the

bottom.

Clean

out

the

exhaust

manifold if it is carboned up.

Examine

the

exhaust

manifold gaskets and

renew

if necessary.

Refit

the

induction and

exhaust

manifold

complete

with

the

carburetter

assembly.

The securing nuts holding

the

manifold should be

tightened

down evenly.

FIt

the

mixture

control.

throttle

controls and

exhaust

pipe

to

the

manifold.

Check and adjust

the

sparking plugs, replace, and

connect

the

high-tension leads

to

the

plugs.

Replace

the

thermostat

body and radiator con-

necti ng hose and

tlghte

n

the

hose elips,

Can n

eet

the

fuel pipe to

the

fueI pump, and refit

the

bonnet.

Switch on

the

ignition, and check

the

fuel connec-

tions

for leaks.

The engine can now be

started

and allowed to run

briskly untl!

the

water

rises

to

a

temperature

between

70° C. and 80° C.

or

160°

F. and

175

0

F.

The valve clearances should

then

be checked care-

fully (see Section

A.27).

A.II

Wishvilles Classic

Automobile Library

Loading...

Loading...