A

THE

ENGINE

slotted nuts. This enables

the

crank.shaft

to

be lifted

from

the

crankcase.

Having cleaned

the

oilways drilled in

the

crankshaft

and

the

bearing journals,

the

new bearings are placed

in position on

their

locating dowels, and

the

crank-

shaft replaced. No scraping is required as

the

bearings

are

machlned to give

the

correct

diametrical clearance

offrom

·0008 in.

to

·003 In. (,02mm.

to

·075 mm.) and

the

side clearanceof from ·0014in. to ·0037in.

(,035

mm.

to

·095 mm.) on

the

centre

bearing. The end bearings

have no end location.

In

the

case of a run bearing, it Is always advisable

to

clean

out

all

the

oJlways In

the

crankshaft and block.

Then wash

out

the

engine base with paraffin.

Seetion

A.8

REMOVAL

AND

REPLACEMENT OF

THE ROCKER

ASSEMBLY

Remove

the

air

cleaner. Detach

the

cylinder head

cover

by removing

the

two

retaining hand nuts and

fibre washers.

Tap back

the

tabs of

the

lock washers from

the

eight

rocker-shaft bracket fixing bolts and unscrew

the

four

1lr

in. and

four!

in. bolts gradually, a

turn

at a time,

until all load has been taken off

the

rocker-shaft, then

completely unscrew

the

bolts.

This

is

important.

Remove

the

rocker

assembly, complete with bracket

and rockers, and wIthdraw

the

eIght push-rods,

marklng

them

so

that

they

may be replaced in

the

same

positions. To dismantle

the

rocker-shaft assembly.

remove

the

two

retaining clips at

either

end of

the

shaft and slide

the

rockers, brackets and springs from

the

shaft. Care should be-taken not

to

lose

the

shaft

bracket washers and a note made of

the

fact

that

the

front

and rear washe rs are .. D "-shaped, whereas

the

washers fitted

to

the

centre

brackets are of

the

normal

pattern

and engage with slots in

the

shaft.

A

note

should also be made In

the

case of later

engines.

that

thrust

washers are fitted

between

the

spacing springs and

the

end

bearing faces of

the

rockers.

Remove

the

plugs from each end of

the

shaft so

that

the

oilways may be cleaned.

Reassembly and replacement Is a reversal of

the

above procedure,

but

care must be taken

to

replace

rockers and springs correctly on

the

shaft.

Section

A.9

REMOVAL

AND

REPLACEMENT OF

THE CYLINDER HEAD

Drain

the

water

system by opening

the

tap at

the

bottom

of

the

radiator and

the

tap

in

the

cylinder

block Immediately below and in front of

the

exhaust

manifold (see Section 0.1).

Remove

the

bonnet

after taking

out

the

two

screws

at

the

rear

end of

the

bonnet

hinge.

Detach high-tension cables from

the

sparking plugs.

Remove

the

sparking plugs, being careful

not

to

break

or

damage

the

porcelain insulators.

Disconnect

throttle

controls and mixture controls.

Uncouple

the

exhaust pipe from

the

manifold.

Disconnect

the

fuel pipe from

the

fuel pump.

Disconnect

the

breather

pipe connection.

Slacken

the

hose clips and remove

the

air

cleaner.

remembering

that

the

central wing

nut

also serves to

hold

the

cleaner

onto

the

air intake pipe, and

that

It

is full of oil.

Disconnect

the

Intake pipe steady on

the

manifold.

Undo

the

four bolts holding

the

intake pipe and

remove

it

complete. Remove

the

bolt clipping

the

exhaust

pipe to

the

gearbox.

Remove

the

four nuts securing

the

induction and

exhaust manifold

to

the

cylinder head and

withdraw

the

clamps

and manifold.

Loosen

the

top

clips on

the

thermostat

by-pass pipe.

Take off

the

top

radiator hose and

thermostat.

Remove

the

011

feed pipe

for

the

rocker gear from

its

attachment

to

the

cylinder head.

It Is also necessary

to

slacken

the

fume pipe and

remove

the

SideInspection cover. If

the

gasket of this

cover

is damaged. a new one must be fitted before

the

engine Is ru n.

A,IO

Fig. A.IO.

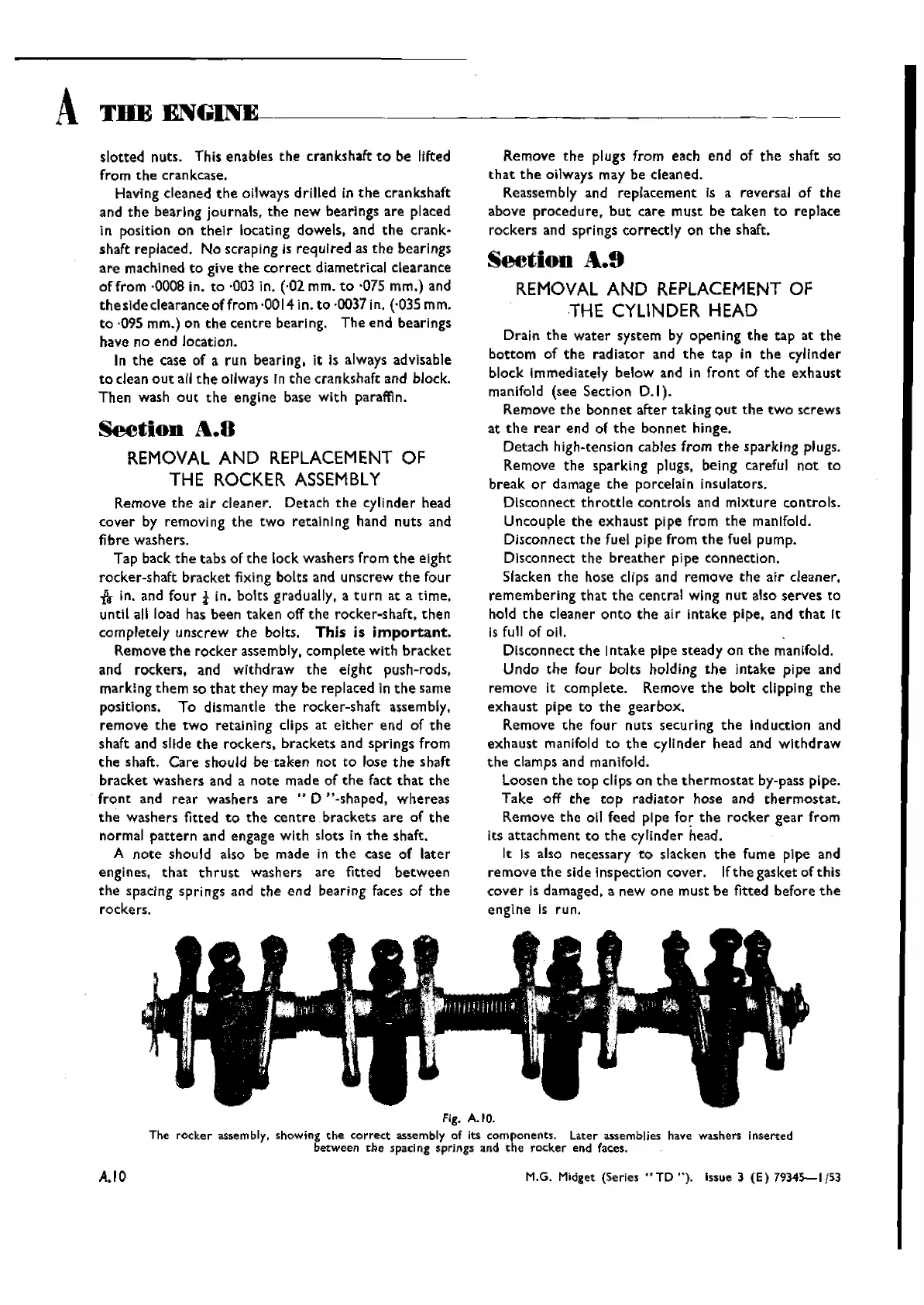

The

rocker

assembly. showing

the

correct

assembly of its components. Later assemblies have washers Inserted

between

the

spacing springs and

the

rocker

end faces.

M.G. Midget (Series

"TD

").

Issue 3

(E)

7934S-lj53

Wishvilles Classic

Automobile Library

Loading...

Loading...