K THE FRONT

SUSPENSION-----

MAINTENANCE

In

ordinary

maintenance it is unlikely

that

it will be

necessary

to

do

more

than

attend

to

replenishment

as

indicated in Section P.6, and check

the

front

wheel

alignment. This Is

the

setting

that

may be affected by

striking high

kerbs

or

similar obstacles.

In view

of

the

Importance

of maintaining

the

correct

steering

geometry

the

use

of

special locating Jigs as

indicated in Fig.

K.2 is

strongly

advised

when

checking

and setting.

Seetion

1i.1

CHECKING

AND

ADJUSTING FRONT

WHEEL ALIGNMENT

When

checking

the

track

width

at

the

front

and

the

rear

of

the

front

wheels, use a suitable

trammel,

or

any special

proprietary

alignment

equipment

available.

The

wheels should run parallel and have no toe-in.

The

correct

setting is

obtained

with equal measure-

ments back and front.

See

that

the

tyres

are

inflated

to

the

correct

pressures.

Set

the

wheels in

the

straight-ahead position.

Set

the

arms of a suitable

trammel

to

the

height of

the

hub

centre.

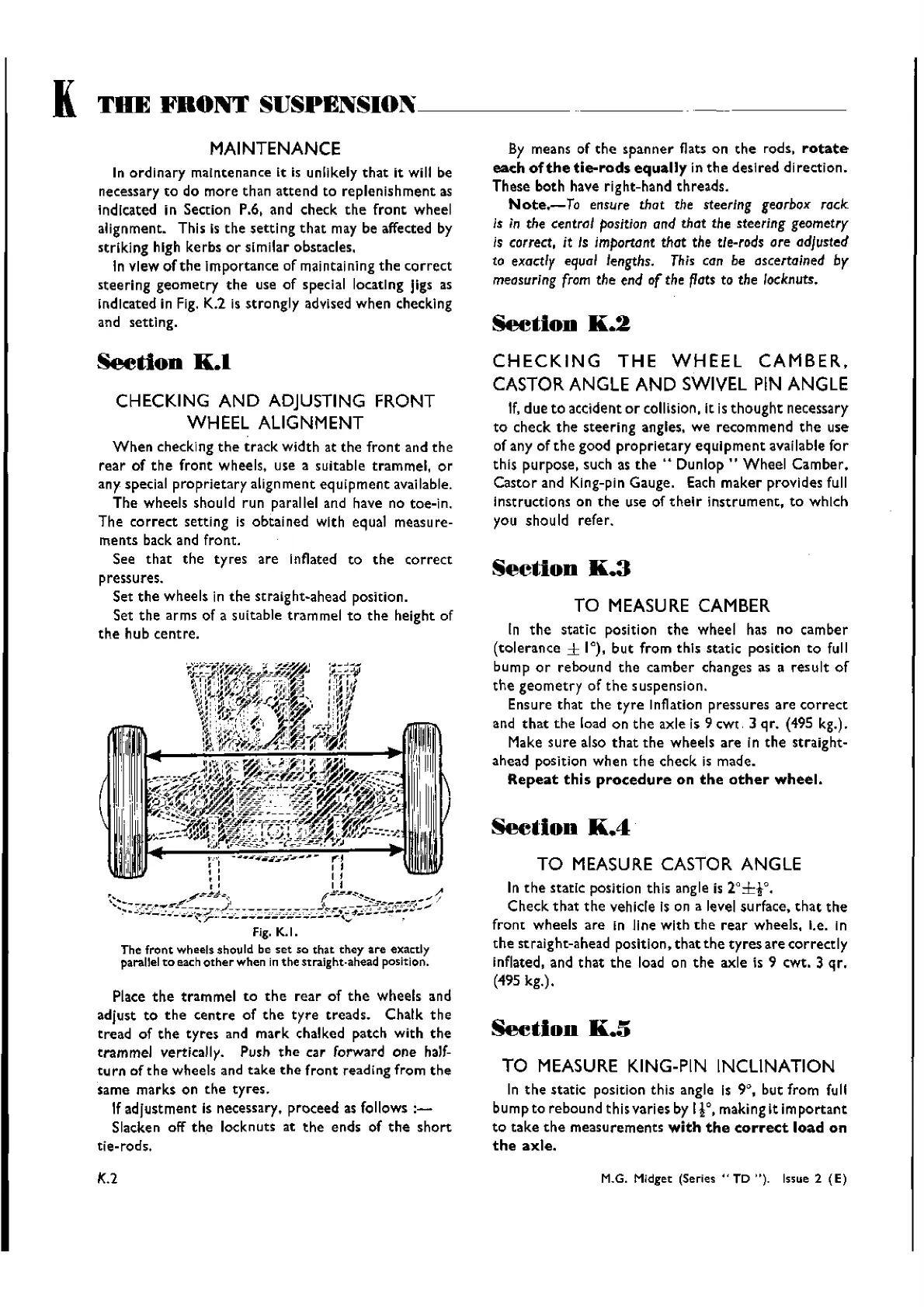

Fig. K.I.

The

front

wheels should be

set

so

that

they

are

exactly

parallel

to

each

other

when in

the

straight-ahead position.

Place

the

trammel

to

the

rear

of

the

wheels and

adjust

to

the

centre

of

the

tyre

treads.

Chalk

the

tread

of

the

tyres

and

mark

chalked patch

with

the

trammel

vertically. Push

the

car forward

one

half-

turn

ef

the

wheels and

take

the

front

reading from

the

same

marks

on

the

tyres.

If

adjustment

is necessary. proceed as follows

:-

Slacken off

the

locknuts at

the

ends of

the

short

tie-rods.

K.2

By means of

the

spanner

flats on

the

rods.

rotate

each

of

the

tie-rods

equally

in th e desired directi

on.

These

both

have right-hand

threads.

Note.-To

ensure that the steering gearbox rack

Is in the

centrClI

position

and that the steering geometry

Is correct, it Is important that the tie-rods

are

adjusted

to exactly

equal

lengths.

This

can be ascertained by

measuring

from

the end

of

the

flats

to the locknuts.

SectIon

K.2

CHECKING

THE

WHEEL

CAMBER,

CASTOR ANGLE

AND

SWIVEL PIN ANGLE

If,due

to

accident

or

collision, It is

thought

necessary

to

check

the

steering

angles, we

recommend

the

use

of any of

the

good

proprietary

equipment

available

for

this purpose, such as

the"

Dunlop"

Wheel

Camber.

Castor

and King-pin Gauge. Each

maker

provides full

Instructions on

the

use of

their

instrument.

to

which

you should refer.

Section

K.3

TO

MEASURE

CAMBER

In

the

static position

the

wheel has no

camber

(tolerance

± 1°),

but

from

this

statlc

position

to

full

bump

or

rebound

the

camber

changes as a

result

of

the

geometry

of

the

suspension.

Ensure

that

the

tyre

Inflation

pressures

are

correct

and

that

the

load on

the

axle is 9

cwt

3 qr. (495 kg.).

Make

sure

also

that

the

wheels

are

In

the

straight-

ahead

posltlon

when

the

check is made.

Repeat

this

procedure

on

the

other

wheel.

See.ion

K.4

TO

MEASURE

CASTOR ANGLE

In

the

statlc position this angle is r±to.

Check

that

the

vehicle Is on a level surface.

that

the

front

wheels

are

in line

with

the

rear

wheels. I.e. in

the

straight-ahead position,

that

the

tyres

are

correctly

inflated, and

that

the

load on

the

axle is 9 cwt, 3

qr.

(495

kg.).

~tiou

K.5

TO

MEASURE

KING-PIN INCLINATION

In

the

static position this angle Is 9°,

but

from fuII

bump to

rebound

thisvaries by

I}O,

making

It

Important

to

take

the

measurements

with

the

correct

load

on

the

axle.

M.G. Midget

(Series"

TD "). Issue 2

(E)

Wishvilles Classic

Automobile Library

Loading...

Loading...