o

THE

"''"HEELS

AND

TYRES,--------

2. Dust

the

inside of

the

cover evenly with french

chalk.

3. Inflate

the

tube until it begins to round out,

then

insert it in

the

cover.

4. Apply a frothy solution of soap and water

generously around

the

entire base of

the

tube,

extending upwards between

the

tyre

beads and

the

tube

itself for at least 2 in. on both sides.

Also apply the solution to

the

bottom and

outside of the

tyre

beads. Do not allow

the

solution to run into

the

crown of the eyre.

The solution must be strong enough to feel

slippery when

the

fingers are

wetted

with

the

solutlon and rubbed together.

5. Mount

the

tyre

on

the

rim Immediately, whilst

the soap solution is still wet.

Push one edge of

the

cover over

the

edge of

the

rim. It will go quite easily if

the

part

fi rst put on is fitted

on

the

opposite side of

the

valve and is pushed right down into

the

rim

base. Move it round so

that

its balance spots

coincide with those of

the

Inner

tube

when it is

inserted with

the

valve

passi

ng through

the

hole In the rim. (Take care

that

the valve.

which is fitted in

the

side of

the

tube, is on

the correct side of

the

rlm.)

6. Before inflating, be

sure

that

the

tyre

beads are

clear of

the

well

ofthe

rim all the way round and

push

the

valve

into

the

tyre

as

far

as

possible

in

order

to

ensure

the

tube

;s

not

trapped

be~een

the

bead

and

the

rim,

then

pull

it

out

again

into

its

correct

position.

7. Inflate slowly until

the

beads are fully seated.

8. Remove

the

valve core to

deflate

the

tube

completely.

9. Reinflate

to

the

correct

working pressu re

(see page

0.1).

This proced ure must be

followed whenever a

tube

is fitted.

The object of

the

double inflation is to permit any

stretched portions of

the

tube

to read]ust themselves

In

the

cover and relieve any local strains In

the

tube.

In an emergency french chalk may be used as a

substitute for

the

soap solution,'

provldedlt

is evenly

and generously applied. This practice, however. is

not recommended.

Repairing

tubes

Punctures or injuries must be vulcanised. Ordinary

patches should only be used for emergencies and

cannot be relied upon.

Patches

are

qui

te

usel

ess

in

the

case

of

synthetic

tubes.

These

must

be

vulcanised

if

punctured

or

otherwise

damaged.

0,4

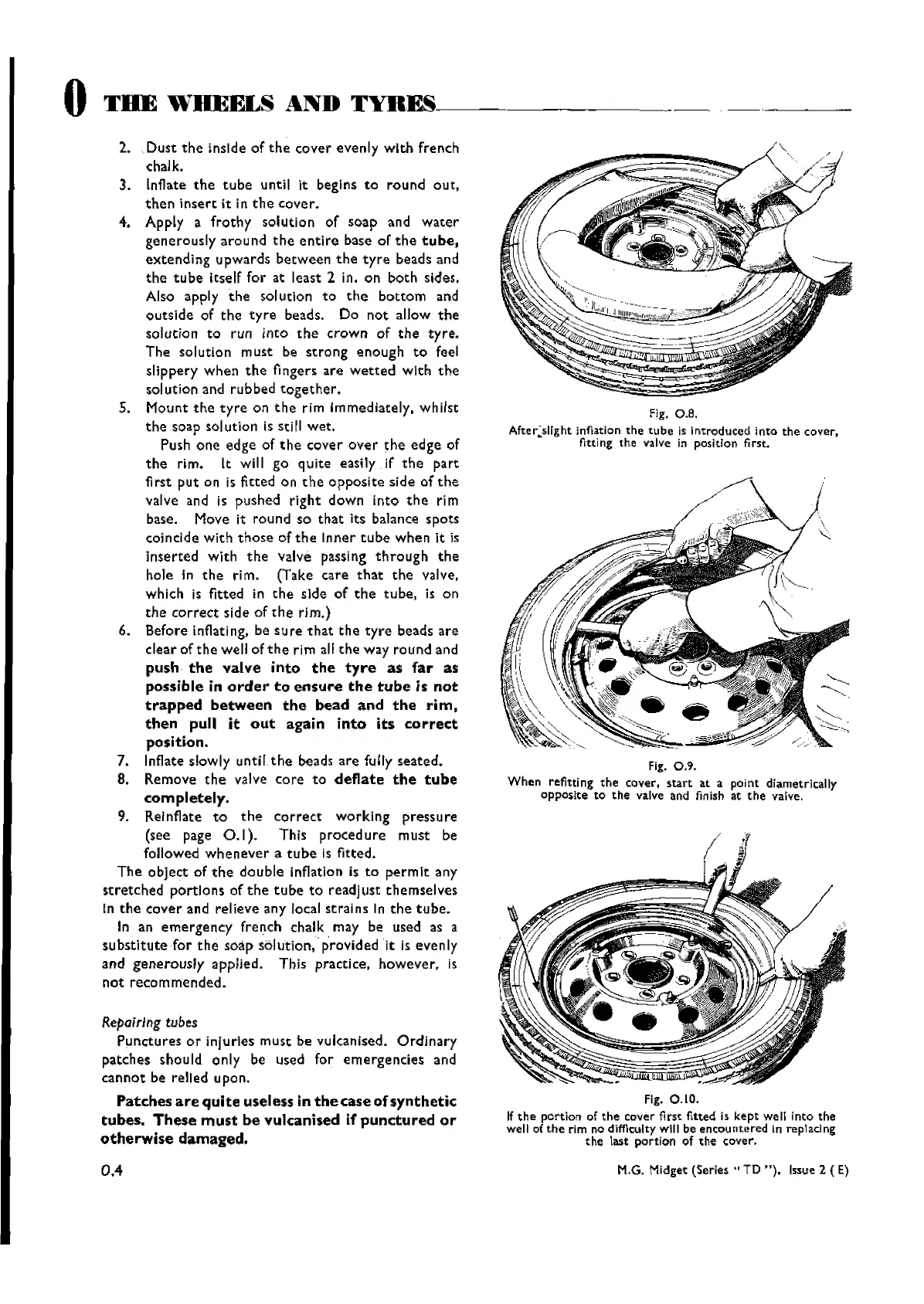

Fig.

0.8.

After~5light

inflation

the

tube

is Introduced

into

the

cover,

flul

ng the valve in position f

rst,

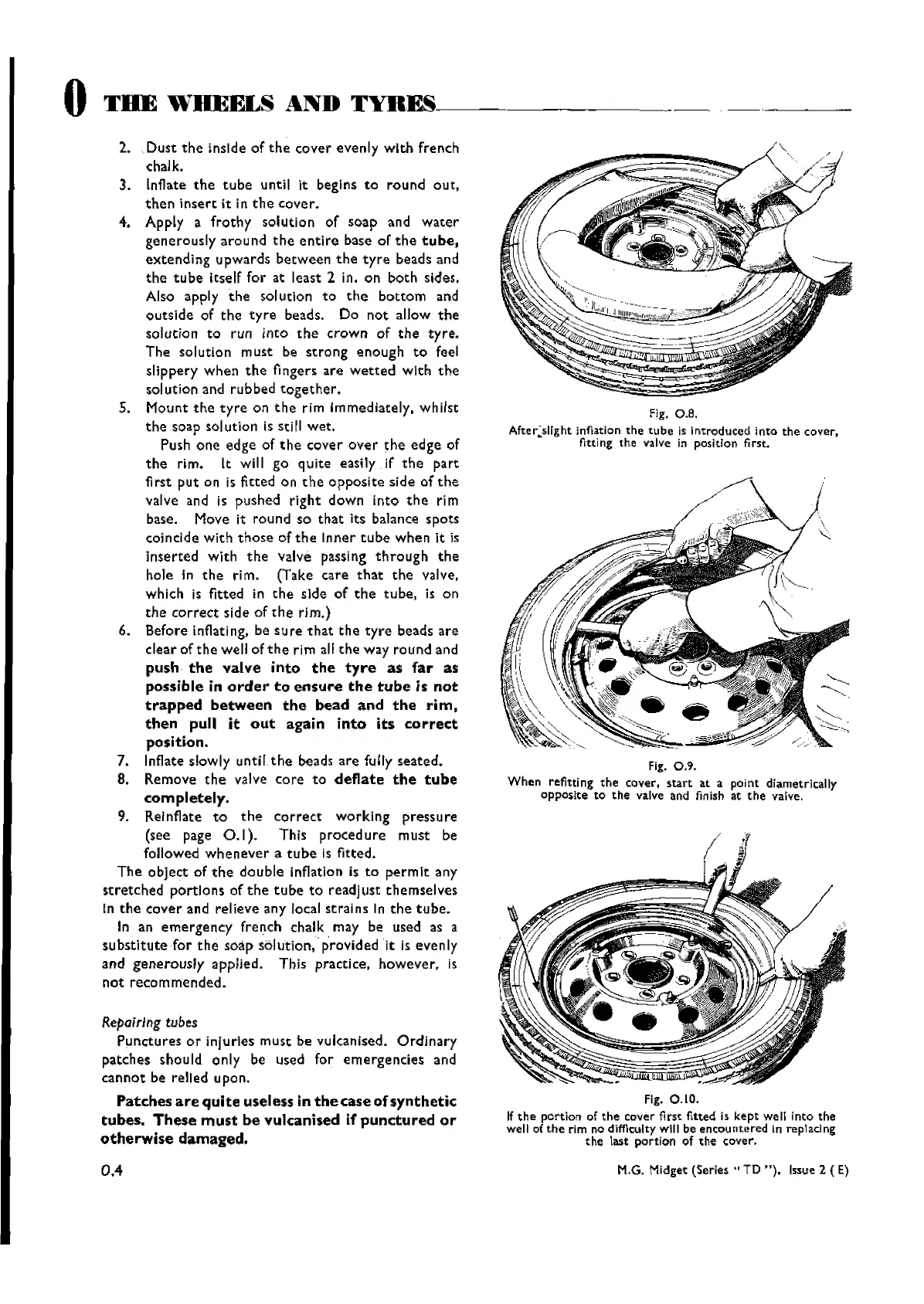

Fig.

0.9.

When

refitting

the

cover,

start

at a point diametrically

opposIte to

the

valve and finish at

the

valve.

Flg.O.lO.

If

the

portjon of

the

cover first fitted is

kept

well Into the

well of

the

rim no difficulty wlll be

encountered

in replacing

the

last

portion

of the cover.

M.G. Midget (Series

"TO

").

Issue 2 ( E)

Wishvilles Classic

Automobile Library

Loading...

Loading...