H

TIlE

BEAR

AXLE-------·-----

Example (2) If

the"

D

..

dimension of

the

old cage

was ·001 in. and

the"

0 .. dimension

on

the

new

cage Is ·005 ln., giving a

difference

of

-·004

In.,

then

this

difference

must

be

subtracted

from

the

original spacer

thickness.

That

Is

to

say. if

the

old

spacer

was

·509 In.

thick,

then

the

new

spacer

must

be ·505 In. thick.

Selecting

an axle cover spacer

In

this

case

subtract

the"

0 " dimension

from

the

" C .. dimension on

both

the

old and

the

new

differ-

ential cages.

If

the

resultant

of

the

dimensions on

the

new

cage

Is

greater

than

that

on

the

old cage,

the

new

spacer

for

the

axle

cover

is less

than

the

old

one

by

the

difference

and vice versa.

Example

(I)

Old:

"C"

·006 in.

-"

0 .. ·005 In.

=

·001

In.

New:

"c"

·007 in.

_II

D "·002 in.

= ·005 In.

The

resultant

with

the

new cage Is

the

greater

by ·004 in••

therefore

the

new

spacer

should be ·004 in. less in

thickness

than

the

old

one.

Example (2)

Old:

.. C "

·002

In.

-"

0 .. ·001 in.

=

'001

In.

New:

" c " ·001 In.

-"

D"

·005 In.

=

-·004

in.

The

old

resultant

Is

here

the

greater

by ·005 ln.,

therefore

the

new

spacer

must

be -005 in.

thicker

than

the

old

one.

Section

U.IO

ASSEM

BUNG TH

EDI

FFERENTIAl

AND

CROWN

WHEEL

The

differential is assembled by first

inserting

the

differential

gears

inside

the.

differential cage

with

their

thrust

washers

in

position.

Note.-When

new

washers

are fitted

it

is necessary to

see that they are

properly

bedded in or

it

may be difficult

to Insert the pinions.

The

differential pinions

are

next

Inserted

through

the

opening

of

the

cage

with

their

distance-pieces

and

thrust

washers.

The

pinions

are

then

rotated

In

the

cage until

they

register

with

the

holes In

the

cage

for

the

shaft.

The

pinion spindle, whIch should be a light push

tit

H.IO

In

the

cage. Is

then

Inserted,

taking

care

to

line up

the

locking

bolt

holes.

Note.-The

slot

In

the shaft can be used as a guide.

Fit

the

locking

bolt

and

turn

up

the

tab

of Its lockl ng

washer.

Fit

the

crown

wheel

to

the

differential cage

after

making

sure

that

the

mating surfaces

are

perfectly

clean and

the

edges

free

from

burrs.

Check

the

crown

wheel

for

truth

by spinning

the

assembly on a

roller

fixture

with

a dial gauge

register-

ing against

the

outer

edge

of

the

crown

wheel.

The

maximum permissible

error

of

alignment

Is ·001 in.

(·025

mm.), and if the figure

registered

Is In excess of

this

the

crown

wheel

should be

removed

from

the

differential cage and

the

flange

of

the

cage checked

for

truth.

If necessary. fit a

replacement

cage.

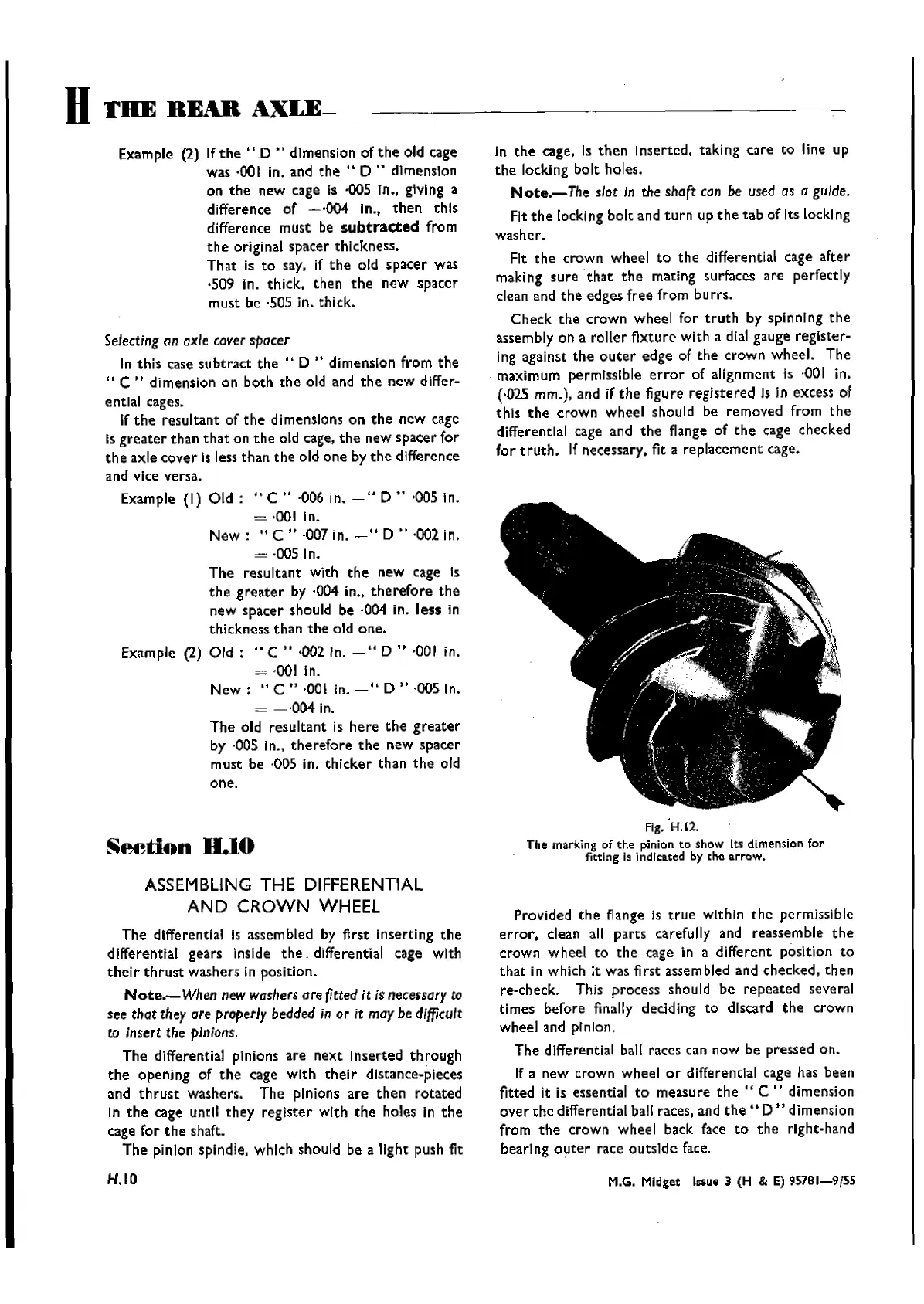

Fig.·H.12.

The marking of the pinion to show

lts dimension for

fitting is

j ndlcated by the

arrow.

Provided

the

flange is

true

within

the

permissible

error,

clean all

parts

carefully and

reassemble

the

crown

wheel

to

the

cage in a

different

position

to

that

in which it was first assembled and

checked,

then

re-check. This

process

shouId be

repeated

seve ral

times

before finally decldlng

to

discard

the

crown

wheel

and pinion.

The

differential ball races can

now

be pressed

on.

If a

new

crown

wheel

or

differential cage has

been

fitted it is essential

to

measure

the"

C " dimension

over

the

differential ball races, and

the"

D"

dimension

from

the

crown

wheel

back face

to

the

right-hand

bearing

outer

race

outside

face.

M.G. Midget lssue 3 (H & E) 95781-9{55

Wishvilles Classic

Automobile Library

Loading...

Loading...