o

THE

\VIlEEL~

AND

TYRES~~~~~~~~~--~-

Should'

applied

Reverse this

procedure

when

replacing

the

road

wheel and

ensure

that

the

wheel stud

nuts

are

tight.

This is

important.

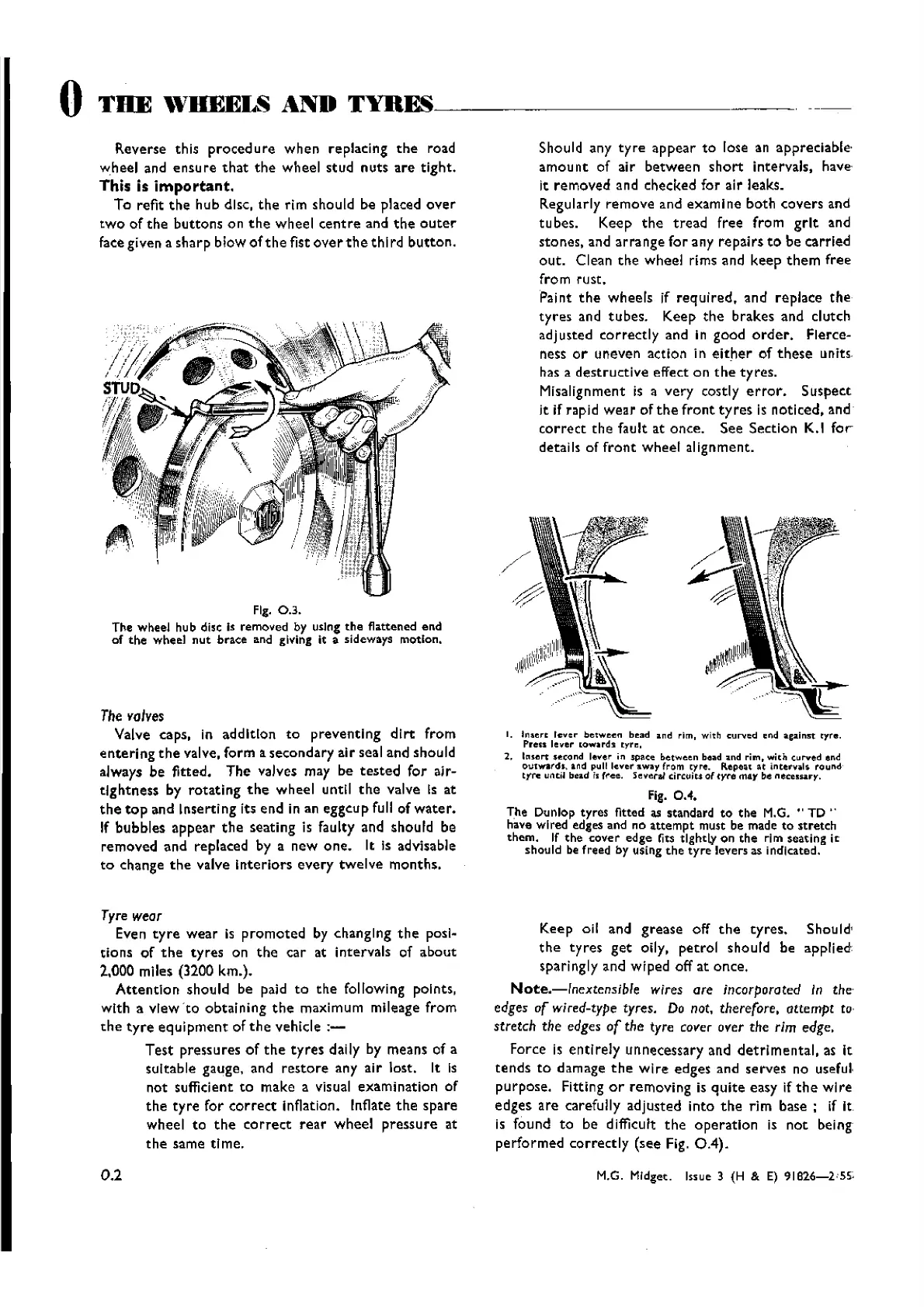

To refit

the

hub disc,

the

rim should be placed

over

two

of

the

buttons

on

the

wheel

centre

and

the

outer

face given a sharp blow of

the

fist

over

the

thl rd

button.

~\

r"':'·

.,,'

Fig.

0.3.

The

wheel

hub disc is removed by usIng

the

f1

..

ttened

end

of

the

wheel

nut

brace and giving it a sideways motion.

The

volves

Valve

caps, in addition

to

preventing

dirt

from

entering

the

valve, form a secondary air seal and should

always be fitted. The valves may be

tested

for air-

tIghtness by

rotating

the

wheel until

the

valve Is at

the

top

and Inserting Its end in an eggcup full of

water.

If bubbles

appear

the

seating is faulty and should be

removed and replaced by a new

one.

It Is advisable

to

change

the

valve

Interiors

every

twelve

months.

Tyre

wear

Even

tyre

wear

Is

promoted

by changing

the

posi-

tions of

the

tyres

on

the

car

at intervals of about

2,000 miles (3200 km.).

Attention

should be paid

to

the

following points,

with

a view

'to

obtaining

the

maximum mileage from

the

tyre

eq ui

pment

of th e veh lcle

:-

Test

pressures of

the

tyres

daily by means of a

suitable gauge, and

restore

any

air

lost. It is

not sufficient

to

make a visual examination of

the

tyre

for

correct

Inflation. Inflate

the

spare

wheel

to

the

correct

rear

wheel

pressure

at

the

same

time.

0.2

Should any

tyre

appear

to

lose an appreciable'

amount

of air

between

short

intervals.

have-

it removed and checked for air leaks.

Regularly remove and examine

both

covers and

tubes. Keep

the

tread

free from

grit

and

stones, and

arrange

for any repairs

to

be Carried

out.

Clean

the

wheel rims and keep

them

free

from rust.

Paint

the

wheels jf

required.

and replace

the

tyres

and

tubes.

Keep

the

brakes and clutch

adjusted

correctly

and in good

order.

Fierce-

ness

or

uneven action In

either

of

these

units,

has a

destructive

effect on

the

tyres.

Misalignment is a very costly

error.

Suspect

it if rapid

wear

of

the

front

tyres is noticed. and

correct

the

fault at once. See Section

K.'

for

details of

front

wheel alignment.

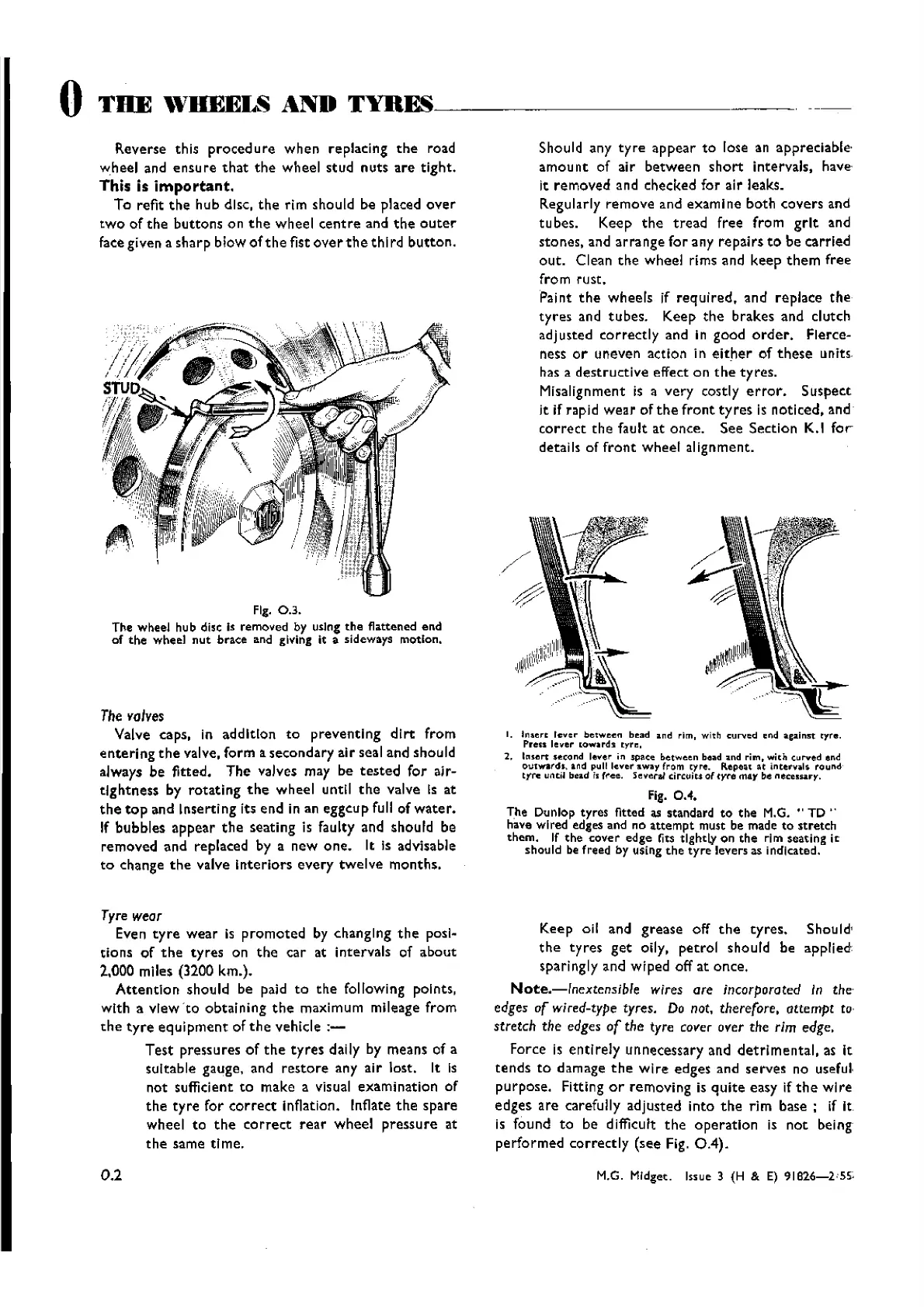

I. IJ'laer-t

rever

betwr:en

bead

and

rim.

with

curved

end

aCain5t

tyre.

Press lever

(OWl

rdt

r:yr

e,

2. In

HI

rt

u:co

nd leve r in .space

between

boad and ri m t wi t n cu

rved

and

o1.nwards. and pull

lever

-awayfrom

tyre.

R.epeat at intety;als.

round

tyre

until

bead

[I (f'ee.

:5~veral

circuits

of

tyr-e may be

necessary.

Fig. OA.

The Dunlop tyres fitted as standard

to

the

M.G.

"TD"

have wired edges and no

attempt

must be made

to

stretch

them. If

the

cover

edge fits tlghtl¥ on

the

rim seating it:

should be freed by using

the

tyre

levers as indicated.

Keep oil and grease off

the

tyres,

the

tyres

get

oily, petrol should be

sparingly and wiped off at once.

Note.-Inextensible wires are incorporated

In

the-

edges of wired-type tyres.

Do

not, therefore, attempt

to-

stretch the

edges

of

the tyre

cover

over the rim edge.

Force is

entirely

unnecessary and

detrimental,

as It

tends

to

damage

the

wire

edges and serves no useful,

purpose. Fitti ng

or

re moving is

quite

easy if th e wire

edges

are

carefully adjusted

into

the

rim

base;

if it

is found

to

be difficult

the

operation

is

not

being

performed

correctly

(see Fig.

0.4).

M.G. Midget. Issue 3 (H & E) 91826-2.-55;

Wishvilles Classic

Automobile Library

Loading...

Loading...