------------------TBE

ENGINE A

Take off

the

gearbox

top

cover

complete

and

secure

a piece of cardboard

over

'the

gearbox

opening in

order

to

prevent

dirt

reaching

the

Inside.

Note.-Great

care

must be taken

when

removing

or

refitting the gear

change

lever and Its

housing.

If the

selector

shaft is

withdrawn

past the

~rst

stop the syn-

chromesh

mechanism

will slide apart and the

synchro-

ballswill

drop

to the

bottom

of the

gearbox.

This

means

the complete

gearbox

must be

dismantled.

Later boxes

are

fitted with an

extended

1st and 3rd

selector

shaft with a retaining

clrdlp

at

the

forward

end which

overcomes

this.

Unscrew

the

screws round

the

pedal

draught

excluder

and disconnect

the

speedometer

drive.

Detach

the

forward

end

of

the

propeller

shaft.

marking

the

flanges so

that

they

can be reassembled

in

the

same position.

On

LHD models it Is necessary

to

disconnect and

lift

the

steering

column

clear

(see

Section A.3).

Disconnect

the

rear

engine mounting and place a

sling

round

the

unit,

just

behind

the

front

mounting

and also

just

forward of

the

flywheel houstng.

Remove

the

unit by lifting It forward and upward.

taking

care

to

disengage

the

steady link from

lu

bracket.

Note.-See

Sectlon

A,38

for

adjustment of engine

mounting.

Section

A.32

REMOVAL

AND

REPLACEMENT OF

FLYWHEEL

In

order

to

take off

the

flywheel

the

engine and

gearbox

unit

should be

removed

from

the

car as

detailed In Section

A.31.

It is advised

not

to

disturb

the

flywheel unneces-

sarily

as It Is essential for it

to

run absolutely

true.

Remove

the

clutch as detailed in Section

E.2.

Remove

the

locking

wire

on

the

flywheel fixing bolts.

Take

out

the

fiXing bolts.

Pull off

the

flywheel with asuitable

extractor,

taking

care

not

to

damage

the

locati ng dowels.

Replacement is a reversal of

this

process.

Check

the

flywheel for accuracy. It should be no

more

th an

·0021

n. ('05 mrn.)

out

of

truth

at any point

when

rotated

with a dial gauge in

contact

with

the

cI

utch face.

Section

A.33

REMOVAL

AND

REPLACEMENT OF

CRANKSHAFT

(Engine

out

of

Chassis)

Remove

the

sump

as detailed

under

SectIon A.2.

Remove

the

fan drtvtng pulley and timing chain

case

~

detailed

under

Section A.I8.

Remove

the

timing chain as detailed

under

Section

A.20.

Remove

the

pistons and connecting rods as detailed

under

Section

A.IO.

Remove

the

two

securing nuts from each main

bearing

cap and

remove

the

caps and bearings.

Note.-It

Is

advisable

to mark

each

bearing

cap and

bearing

to ensure their correct

position

for

subsequent

replacement.

Remove

the

crankshaft and flywheel.

If necessary remove

the

flywheel as detailed

under

Section A.32.

but

only

If necessary.

Replacement of

the

crankshaft is

carried

OUt

In

the

reverse

manner

to

that

detailed

for

removal,

but

before doing so, clean

the

oilways In

the

crankshaft.

In

order

to

clean

out

the

ollways in

the

crankcase.

the

camshaft, filter,

011

pump and pipes should be

removed.

All bearings and

other

parts should be cleaned

carefully before replacement, and care must be

taken

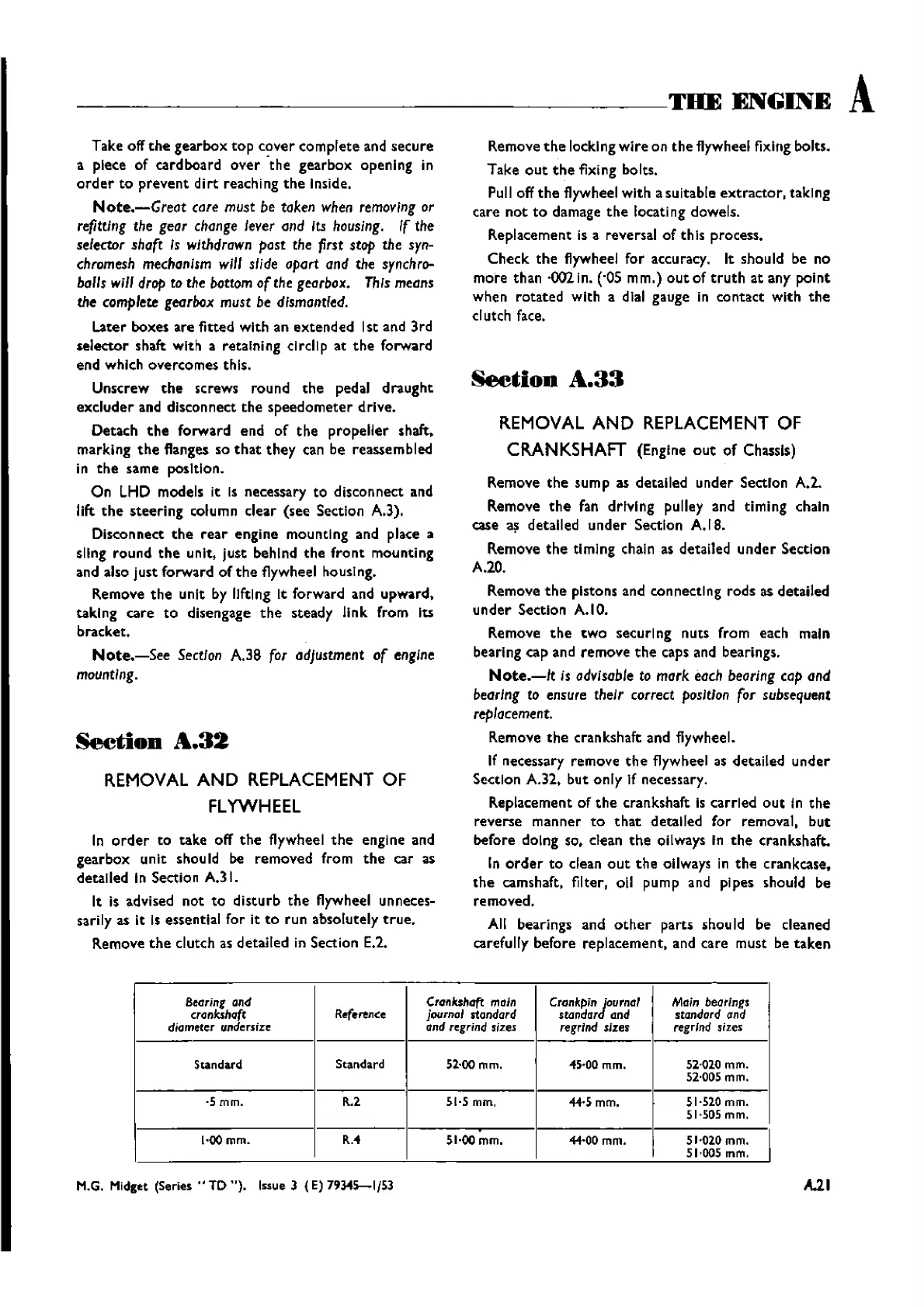

BeGring

and

Crankshaft

main

Crankpin

Journal

Main bearings

crankshaft Reference journal standard

standar and standard and

diameler

undersize

and regrind sizes

regrind

sizes

regrind 5;zes

Standard

Standard

52·00 mm. 45·00 mm. 52·020 mm.

52·005 mm.

·5mm.

R.2 51·5 mm.

44·5 mm.

51·510 mm.

51·505 rnm,

,

I

I·oomm.

R.-4

51·00 mm.

-44·00mm.

51·020mm.

51·005 mm.

M.G. Midget

(Series"

TO

").

Issue

3 (E) 79345-1{53

A.21

Wishvilles Classic

Automobile Library

Loading...

Loading...