spring washer is not a reliable conductor, and the brass

tag

must

therefore bear directly against the head ofthe

screw.

All

four

connections, namely

the

two

ends

of

the

earthing

tag and

the

two

ends of

the

coli, should be

soldered.

The

coil end leading

to

the

terminal

should be

soldered

to

its tag and not

to

the

retainIng

nut. In

the

case of

the

terminal

screw which holds

the

bakelite

cover

in position, similar considerations

apply,

the

assembly being

:-Spring

washer

(I),

wiring tag (2), lead

washer

(3), and recessed

nut

(04)

(see Fig. SA). A lead

washer

has been found

necessary at this

point

as some few cases of had

connection have been found.

Under

no circumstances

---THE

FUEL SYSTEM B

2. Flt

the

impact

washer

In

the

recess of

armature.

3. Screw

the

armature

In position.

4. Place

the

eleven gulde rollers in position around

the

armature.

No

jointing

compound

may

be

used

on

the

diaphragm.

5. Hold

the

magnet assembly in

the

left hand, in

an approximately horizontal

posltlon,

6. Push

armature

in with

the

thumb

of

the

right

hand. pushing firmly

but

steadily. If

the

contact

breaker

throws

over.

the

armature

should be screwed in

farther

until it ceases

to

do

so;

It should

then

be unscrewed one-sixth

of a

turn

at a

time,

until a position is found

where

the

contact

breaker

rocker

Just

throws

Fig_

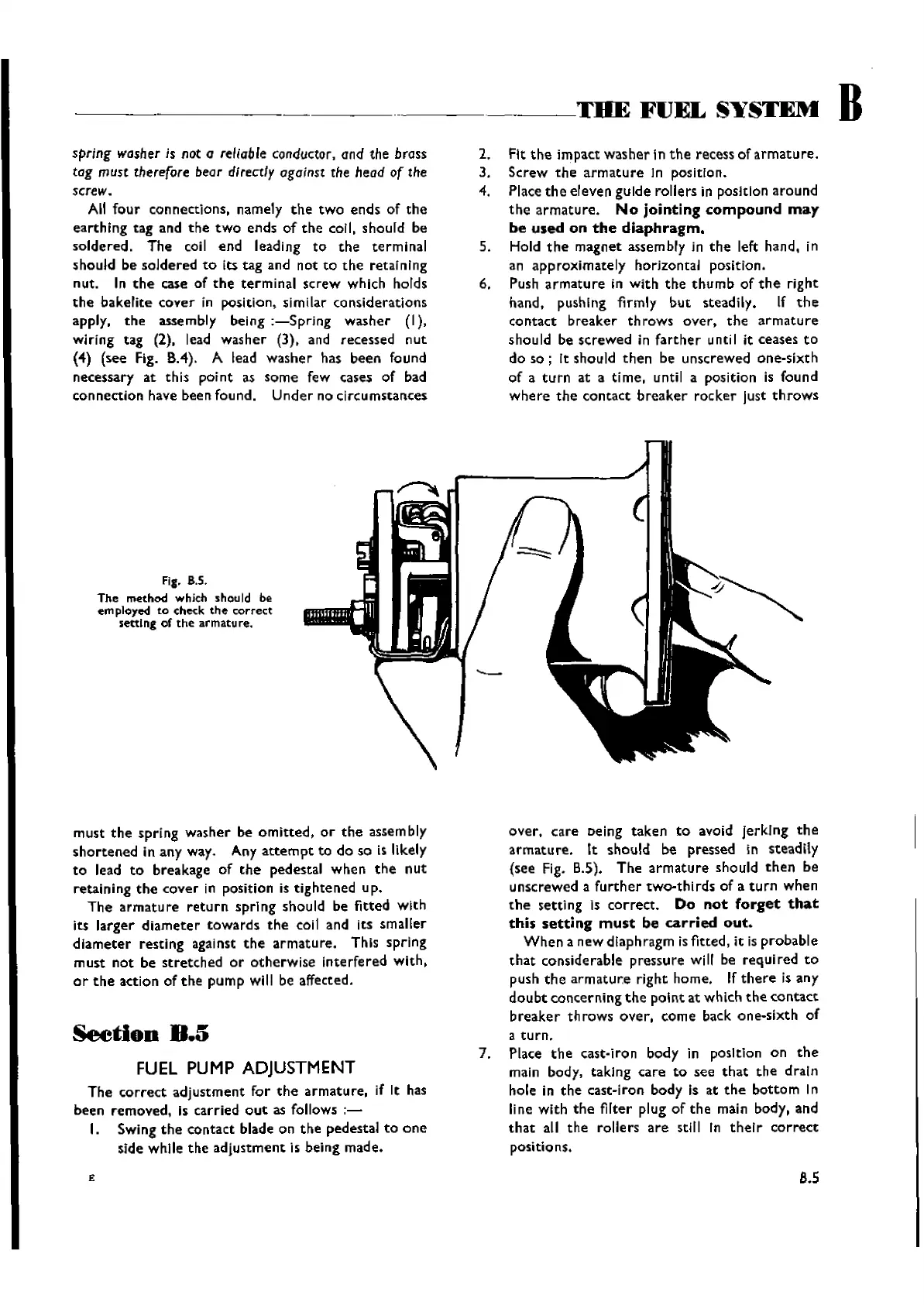

B.S.

The

method

whith

should be

employed

to

check

the

correct

setting of the armature.

must

the

spring washer be

omitted,

or

the

assembly

shortened

in any way. Any

attempt

to do so is likely

to

lead

to

breakage of

the

pedestal

when

the

nut

retaining

the

cover

in posltlon is

tightened

up.

The

armature

return

spring

should be fitted with

its

larger

diameter

towards

the

coil and its smaller

diameter

resting against

the

armature.

This spring

must

not

be

stretched

or

otherwise

interfered

with,

or

the

action of

the

pump

will be affected.

SeetiOD

D.5

FUEL

PUMP

ADJUSTMENT

The

correct

adjustment

for

the

armature,

if It has

been removed, Is carried

out

as follows

;-

I. SWing

the

contact blade on

the

pedestal

to

one

side while

the

adjustment

is being made.

£

over.

care

eelng

taken

to

avoid Jerking

the

armature.

It should be pressed in steadily

(see Fig. B.S).

The

armature

should

then

he

unscrewed a

further

two-thirds

of a

turn

when

the

setting is

correct.

Do

not

forget

that

this

setting

must

be

carried

out.

When

a new diaphragm isfitted, it is

probable

that

considerable pressure will be

required

to

push

the

armature

right home. If

there

is any

doubt

concerning

the

point

at which

the

contact

breaker

throws

over,

come back one-sixth of

a

turn.

7. Place

the

cast-iron body in posltlon on

the

main body, takIng

care

to

see

that

the

draln

hole in

the

cast-iron body is at

the

bottom

In

line with

the

filter plug of

the

main body, and

that

all

the

rollers

are

stlll In

thetr

correct

positions.

8.5

Wishvilles Classic

Automobile Library

Loading...

Loading...