G

TIlE

PROPELLER

SHAFT---

---

Section

6.4

DISMANTLING THE

PR.OPELLER.

SHAFT

Unscrew

the

dust

cap at

the

rear

end of

the

sliding

[oint and pull

the

joint

off

the

splined shaft. Remove

the

enamel and

dirt

from

the

snap rings and bearing

races. Remove

all

the

snap rings by pinching

their

ears

together

with

a pair

of

thin-nosed pliers and

prising

them

out

with a screwdriver.

Ifa ring does

not

slide

out

of

its

groove

readily,

tap

the

end

of

the

bearing race slightly

to

relieve

the

pressure

against

the

ring. Holding

the

joint

in

one

hand

with

the

splined sleeve yoke on

the

top,

tap

the

radius

of

the

yoke lightly

with

a

copper

hammer.

The

bearing should begin

to

emerge;

turn

the

joint

over

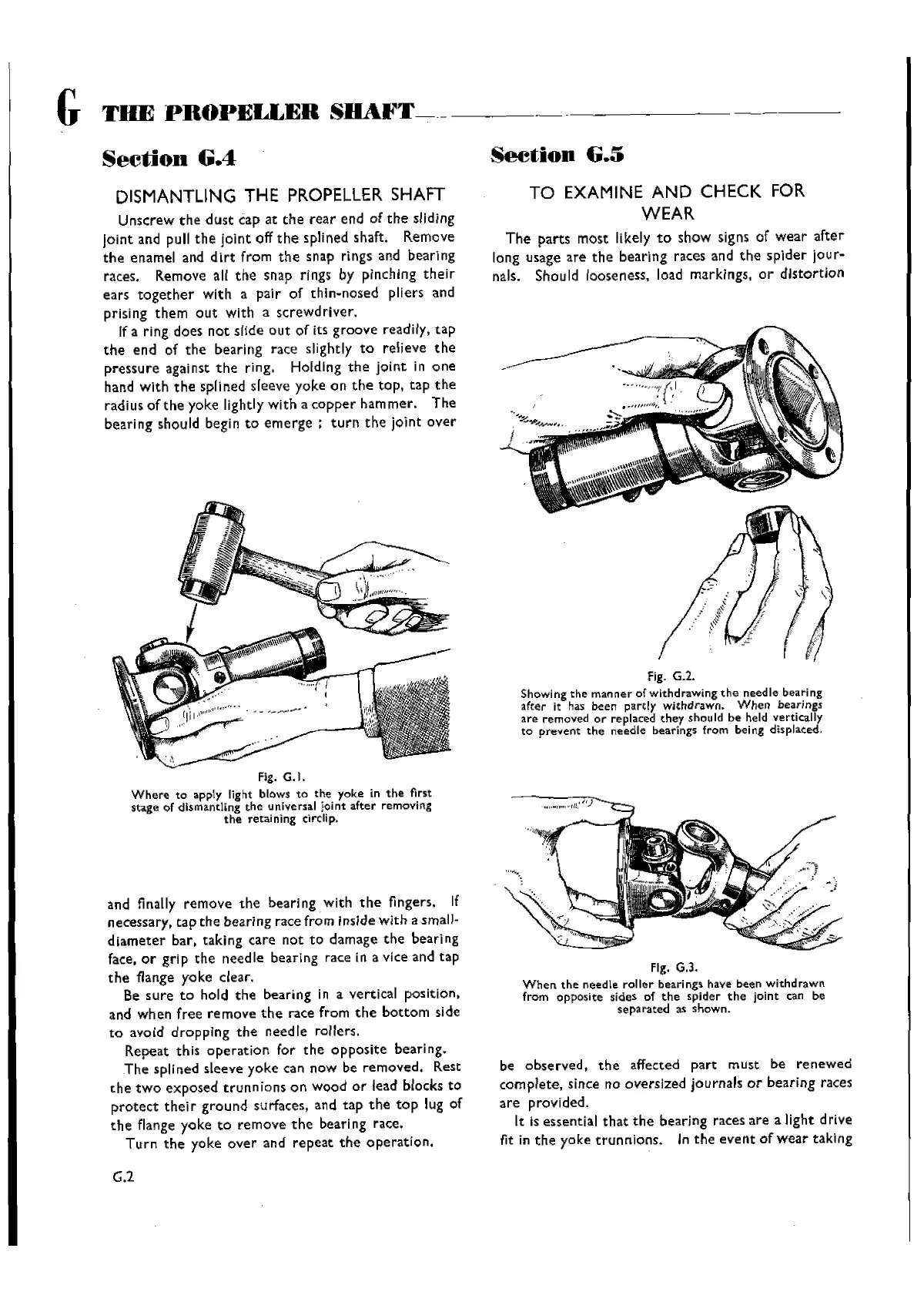

Fig.

G.!.

Where

to

apply light blows

to

the

yoke

in

the

first

stage of dismantling

the

unlve rsal ioint

after

removing

the

retalning elrcllp.

and finally remove

the

bearlng with

the

fingers. If

necessary,

tap

the

bearing race from inside

with

a

small-

diameter

bar, taking care

not

to

damage

the

bearing

face.

or

gri p

the

need Ie bearing race in a vice and tap

the

flange yoke

dear.

Be

sure

to

hold

the

bearing in a vertical position,

and when

free

remove

the

race from

the

bottom

side

to

avoid droppIng

the

need Ie rollers.

Repeat thls

operation

for

the

opposite

bearing.

The

splined sleeve yoke can now be removed. Rest

the

two

exposed

trunnions

on

wood

or

lead blocks to

protect

their

ground

surfaces, and

tap

the

top

lug of

the

flange yoke

to

remove

the

bearing race.

Turn

the

yoke

over

and

repeat

the

operation.

G.2

Section

G.5

TO EXAMINE

AND

CHECK FOR

WEAR

The

parts

most

likely

to

show signs of

wear

after

long usage are

the

bearing races and

the

spider

jour-

nals. Should looseness, load markings,

or

dIstortion

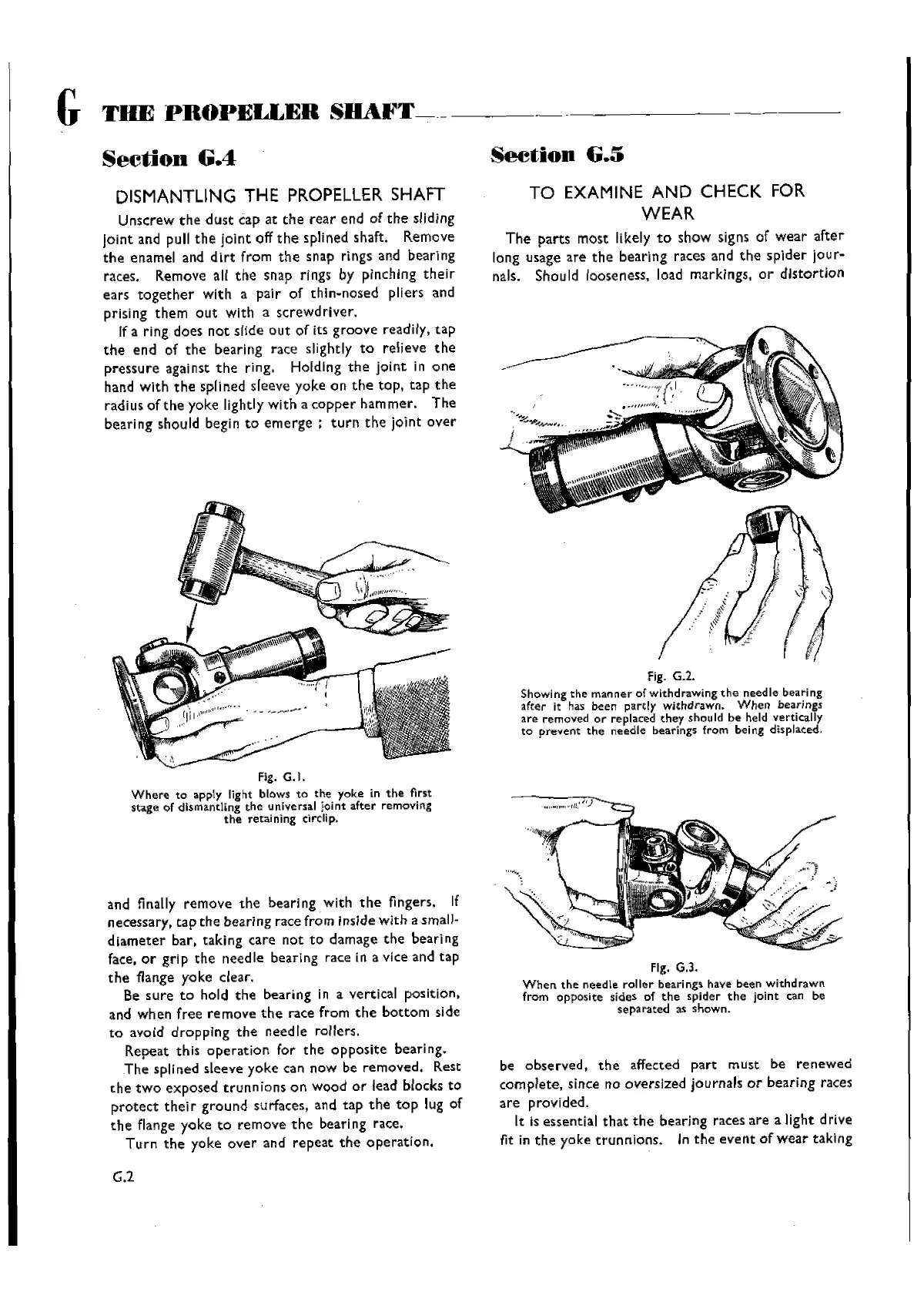

Fig. G.2.

Showi ng

the

man

ner

of

withd

rawing

the

need Ie beari ng

after

it has

been

partly

withdrawn.

When

bearings

are

removed

or

replaced

they

shou Id be held vertically

to

prevent

the

needle bearings from being displaced.

Fig.

GJ.

When

the

needle

roller

bearings have

been

withdrawn

from

opposite

sides of

the

spider

the

joint

can be

separated

as

shown.

be

observed,

the

affected

part

must

be

renewed

complete, since no oversIzed journals

or

bearing races

are

provided.

It is essential

that

the

bearing races

are

a light drive

fit in

the

yoke

trunnions.

In

the

event

of

wear

taking

Wishvilles Classic

Automobile Library

Loading...

Loading...