---

THE

IIYDRAUL'C

DAMPERS

L

While

adding fluid

the

lever

arm

must

be

worked

throughout

Its full

stroke

to

expel

any alr

that

m:l.Y

be

present

in

the

operating

chamber.

If

the

addition of fluid gives no

Improvement

a

replacement

damper

should be

fitted.

Too

much resistance, I.e.

when

it is

not

posslble

to

move

the

lever

arm

by hand, indicates a

broken

internal

part

or

a seized piston.

Seetlon

L.5

REPLACEMENT OF THE

REAR

DAMPER LINK BEARINGS (GIRLlNG)

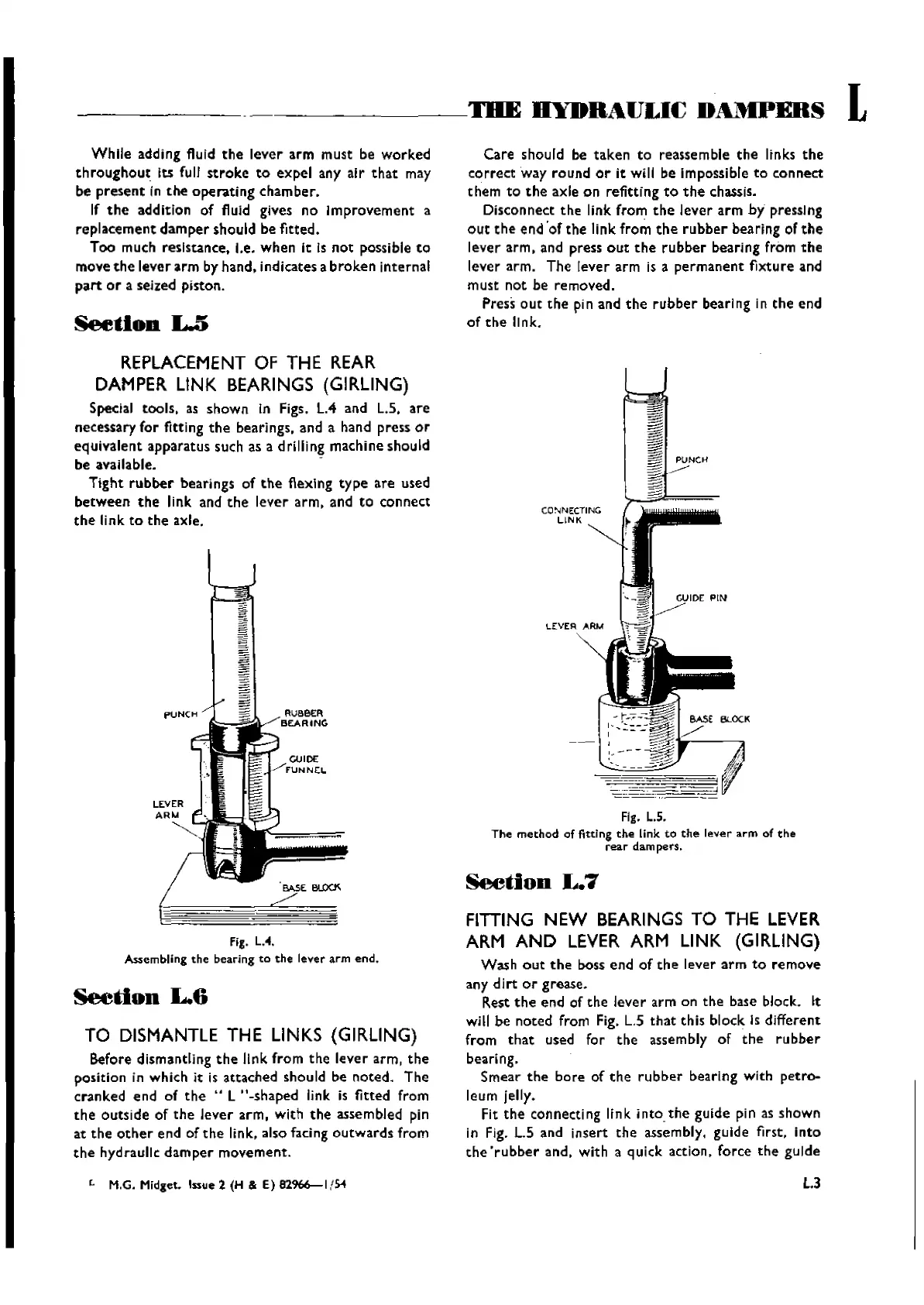

Special tools, as

shown

in Figs. LA and LS,

are

necessary for fitting

the

bearings, and a hand press

or

equivalent

apparatus

such as a drilling mach ine shouId

be available. -

Tight

rubber

bearings

of

the

flexing

type

are

used

between

the

link and

the

lever

arm,

and

to

connect

the

link

to

the

axle.

GUIDE

FUNNEl.

Fig. L....

Assembling

the

bearing

to

the

lever

arm

end.

Seetion

L6

TO DISMANTLE THE LINKS (GIRLlNG)

Before dismantling

the

link

from

the

lever

arm,

the

position in which it is attached should be

noted.

The

cranked

end

of

the

.. L

"-shaped

link is fitted from

the

outside

of

the

lever

arm,

with

the

assembled pin

at

the

other

end

of

the

link, also facing

outwards

from

the

hydraulic

damper

movement.

r, M.G. Midget. Issue 2 (H

&:

E) 82966-1,154

Care

should be

taken

to

reassemble

the

links

the

correct

way

round

or

it will be impossible

to

connect

them

to

the

axle on refitting

to

the

chassis.

Disconnect

the

link

from

the

lever

arm

by pressing

out

the

end

'of

the

link

from

the

rubber

bearing of

the

lever

arm,

and press

out

the

rubber

bearing from

the

lever

arm.

The

lever

arm

is a

permanent

fixture

and

must

not

be

removed.

Press

out

the

pin and

the

rubber

bearing in

the

end

of

the

link.

CO""NECTING

LINK

Fig.

L.S.

The

method

of fitting

the

link

to

the

lever

arm

of

the

rear dampers.

Section

L.7

FITTING

NEW

BEARINGS

TO THE

LEVER

ARM

AND

LEVER

ARM LINK (GIRLlNG)

Wash

out

the

boss

end

of

the

lever

arm

to

remove

any

dirt

or

grease.

Rest

the

end

of

the

lever

arm

on

the

base block. It

will be

noted

from Fig. lo5

that

this

block Is different

from

that

used for

the

assembly

of

the

rubber

bearing.

Smear

the

bore

of

the

rubber

bearing

with

petro-

leum jelly.

Fit

the

connecting link

into

the

gulde pin as

shown

in Fig. loS and

insert

the

assembly, gulde first,

into

the'

ru

bber

and,

wit

h a quick action, force

the

guIde

L3

Wishvilles Classic

Automobile Library

Loading...

Loading...