~-----,------------_THE

ENGINE

A

SeetioD

A.29

GRINDING

AND

TESTING THE VALVES

AND

THEIR SEATINGS

Each valve

must

be cleaned

thoroughly

and carefully

examined

for

pitting. Valves in a

pitted

condition

should be refaced

with

a suitable

grinder

or

alternatively replaced

with

new

valves.

If

the

valve

seats

show

slgns

of

plttlng

or

uneve nness,

they

should

be

trued

by

the

use

of

a suitable

grinder

or

a special

cutter

such as Tool

No.

301075(Section

Q).

When

using a

cutter,

care should be exercised

to

remove

only

as little metal as is necessary

to

ensure

a

true

surface.

fiB.

A.D.

Uneven valve

seats

an

be

trued

with

a special

cutter.

All valves,

when

fitted

at

the

factory,

are

numbered

on

their

heads from I

to

8. and should be replaced in

the

correspondtng valve ports,

No.

I valve being fitted

to

the

port

nearest

the

front

of

the

engi ne.

When

replacement

valves

are

fitted.

th eyshould be n

umbered

to

Identify

the

port

to

which

they

belong.

The

valve face should be smeared lightly

with

fine

or

medium

grade

carborundum

paste, and

then

ground

to

In

seat, using

the

suction

grinder.

Part

No.

66893.

Avoid

the

use of excessive

quantities

of

grinding

paste;

see

that

it remains In

the

region

of

the

valve

seating only and does

not

reach

the

working

surfaces

of

the

engine. A light coli spring placed

under

the

valve head will assist considerably in

the

process

of

grinding.

The

valve should be lapped

to

its

seat

with

a semi-rotary

motion

and occasionally allowed

to

rise

by

the

pressure of

the

light coil spring. ThIs assists

in

spreading

the

paste evenly

over

the

valve face and

M.G. Mid,et. Issue 5 (H & E) 93692-5/55

seat. It Is necessary

to

carry

out

the

grinding

opera-

tion until a dull, even

matt

surface.

free

from blemish.

Is prod

uced

on

the

valve

seat

and face. If

the

valve

seat, which Is at 30°, Is found

to

be wide, it should be

reduced

with a 15°

cutter

to a

width

of

2 mrn, (,080 ln.)

for

the

exhaust

and

1·1

mm. (·043 In.] for

the

inlet

seats.

On

completion.

the

valve seats and

ports

should be

cleaned

thoroughly

with

paraffin-soaked rag,

dried,

and

then

thoroughly

cleaned by

compressed

air.

The

valves should be washed in paraffin

(kerosene),

and all

traces

of

grInding

paste

removed.

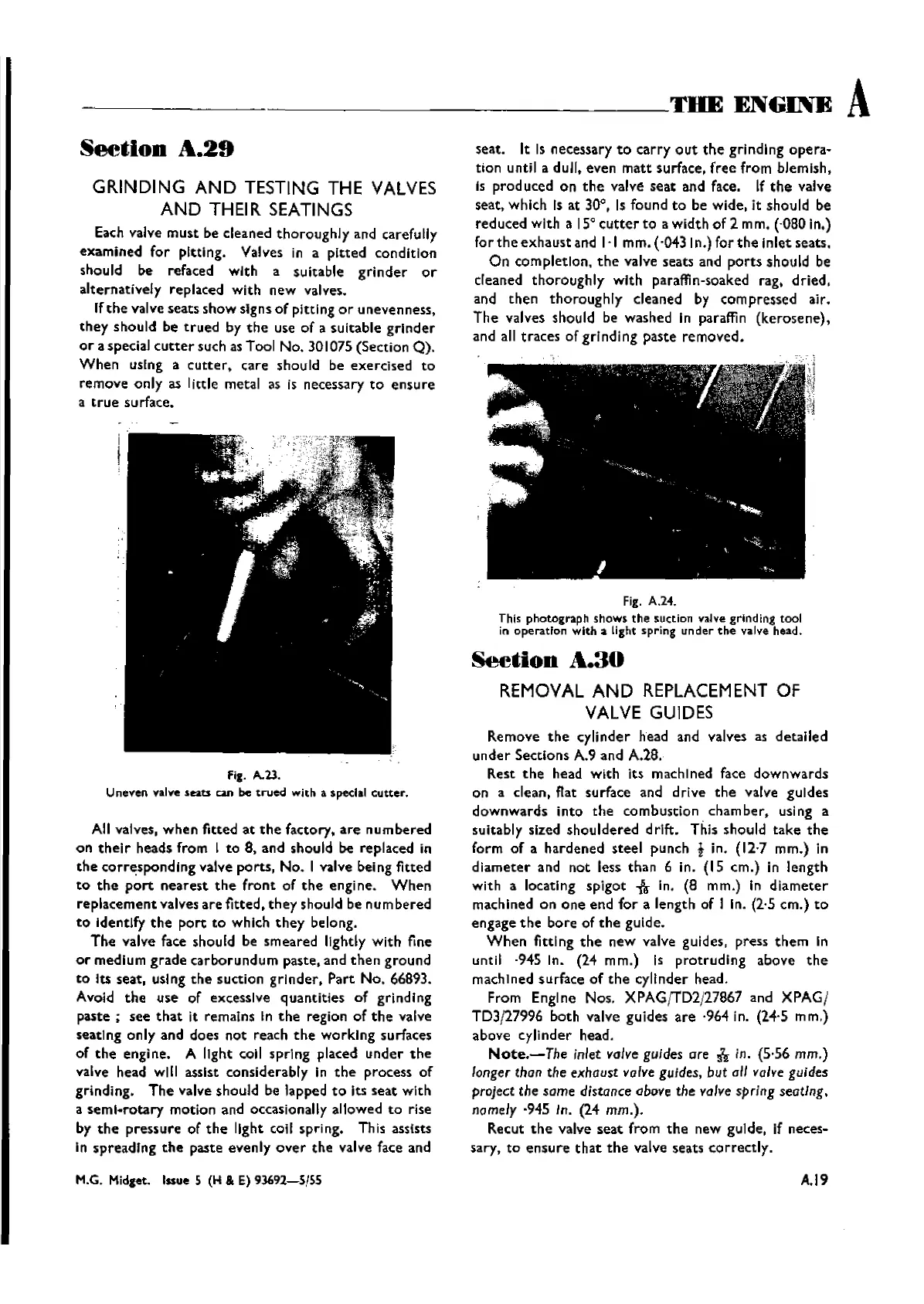

fig. A.24.

This

photograph

shows

the

suction

v<l.lve

grinding tool

in

operatfon

with

a light

spring

under

the

valve head.

SeetiOD

A.3D

REMOVAL

AND

REPLACEMENT OF

VALVE GUIDES

Remove

the

cylinder

head and valves as

detailed

under

Sections A.9 and

A.2B.

Rest

the

head

with

its machined face

downwards

on a clean. flat surface and drive

the

valve guides

downwards

into

the

combustion

chamber.

using a

suitably sized

shouldered

drift. This should

take

the

form

of

a

hardened

steel

punch i in.

(12·7

mm.) in

diameter

and

not

less

than

6 in. (15

cm.)

in

length

with a locating

spigot

-.&-

in. (8 mm.) In

diameter

machined on

one

end

for

a length of I in. (2·5

cm.)

to

engage

the

bore

of

the

gulde.

When

fitting

the

new

valve guides, press

them

in

until

·945 In. (24 mm.) is

protruding

above

the

machIned surface

of

the

cylinder head.

From Engine Nos. XPAG;TD2J27867 and XPAG/

TD3/27996 both valve guides

are

·964 in. (24·5 mm.)

above

cylinder

head.

Note.-The

inlet valve guides are nin. (5·56 mm.)

longer

than the exhaust valve guides, but all valve guides

project

the same distance

above

the valve spring seating.

namely

·945 In. (24 mm.).

Recut

the

valve

seat

from

the

new guide, if neces-

sary,

to

ensure

that

the

valve seats

correctly.

A.19

Wishvilles Classic

Automobile Library

Loading...

Loading...