--- -- --

--

-- -

TDE

PROPELLER

SHAFT

G

place in

the

yoke

cross-holes.

rendering

them

oval.

the

yokes

must

be

renewed.

In case of

wear

in

the

cross-

holes in

the

fixed yoke. which is

part

of

the

tubular

shaft assembly, it should normally be replaced by a

complete

tubular

shaft assembly.

Only

in

the

case

of

emergency

should any

attempt

be made

to

renew

this

yoke.

Seetion

G.6

REASSEMBLING

THE

PROPELLER.

SHAFT

See

that

all

the

drilled holes in

the

journals are

thoroughly

cleaned

out

and free from grease.

Assemble

the

needle rollers In

the

bearing races and

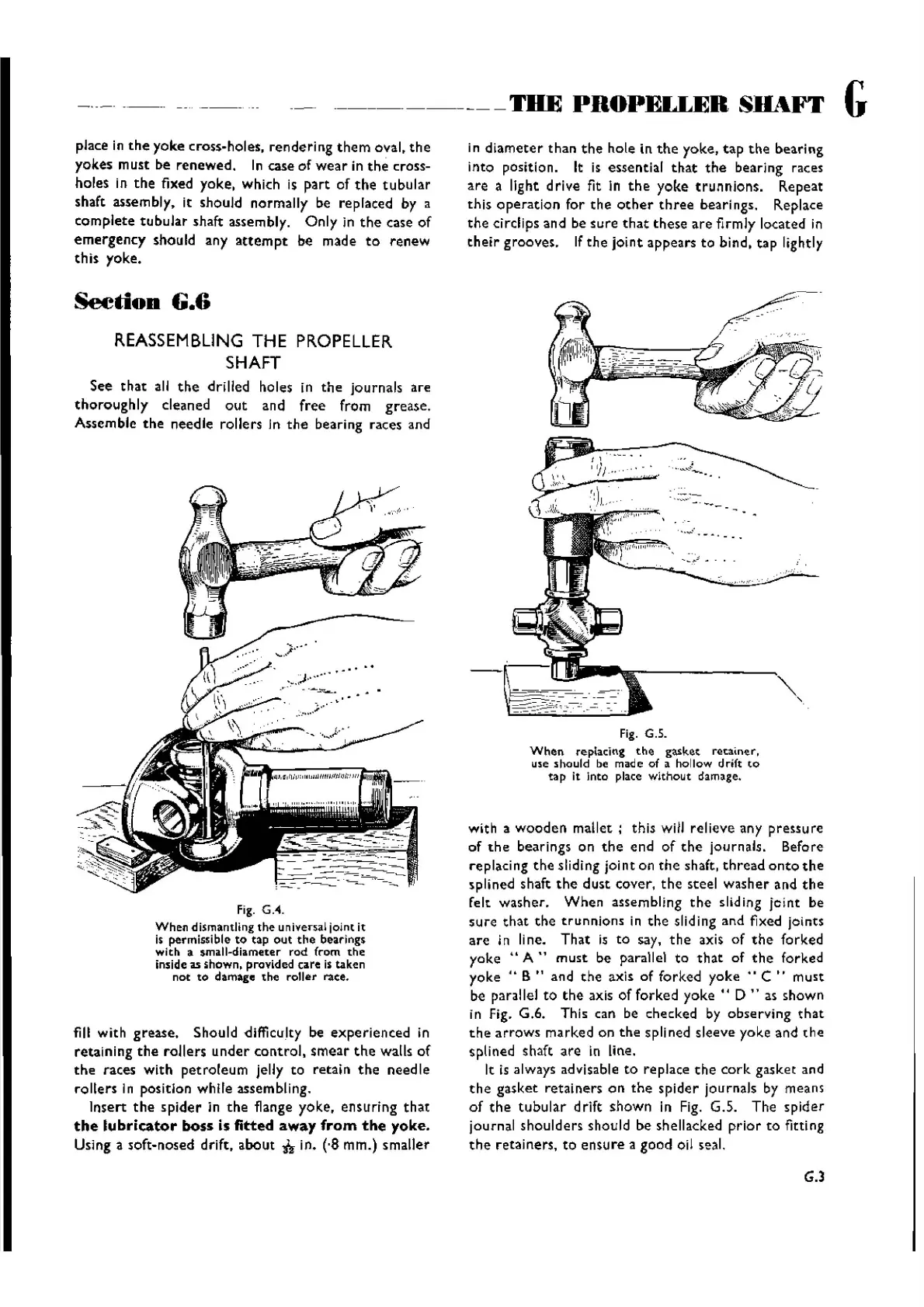

Fig.

GA

When

dismantling

the

universal joint it

is permissible

to

tap

out

the

bear

ings

witll a small-diameter rod from tile

inside as

shown,

provided

care

is taken

not to damage the

roller

race.

fill with grease. Should dffflculty be

experienced

in

retaining

the

rollers

under

control.

smear

the

walls

of

the

races with

petroleum

jelly to retain

the

needle

rollers

In position while assembling.

Insert

the

spider

in

the

flange yoke.

ensuring

that

the

lubricator

boss

is

fitted

away

from

the

yoke.

Using a soft-nosed drift.

about

'*

in. (,8 mm.) smaller

in

diameter

than

the

hole in

the

yoke.

tap the

bearing

into position. It is essential

that

the

bearing races

are

a light

drive

fit In

the

yoke

trunnions.

Repeat

this

operation

for

the

other

three

bearings. Replace

the

circlips and be

sure

that

these

are

firmly located in

their

grooves. If

the

joint

appears to bind.

tap

lightly

....

.....

...

..t-...... .

-' . '-

....

~

,

.

--..;..--'-'--

-

-

.

,

~

- . . . . .

' ' "/ .' : .

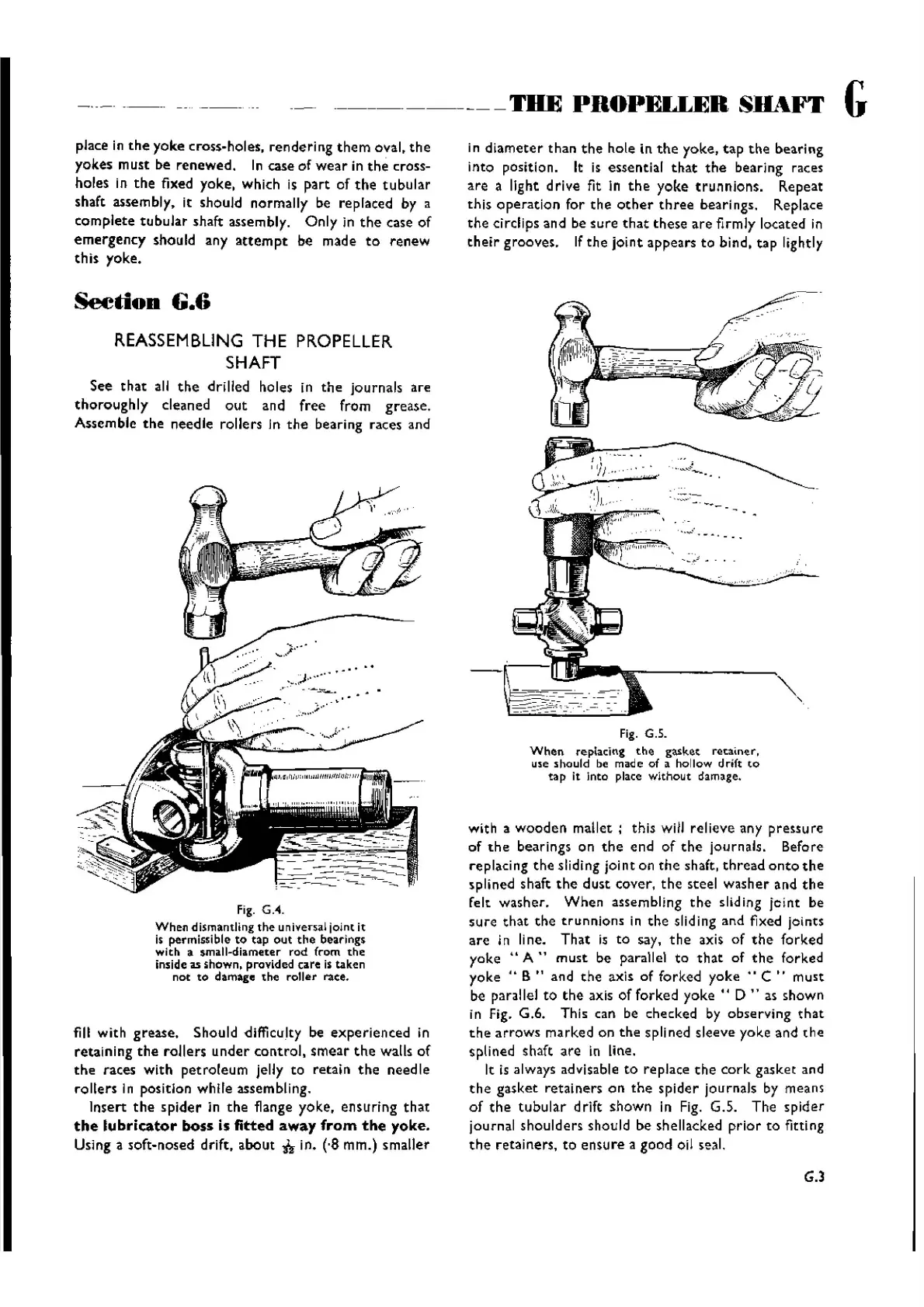

Fig. G.5.

When

replacing

the

gasket

reuiner.

use should be made of a hollow drift

to

tap

It Into place w

ithout

damage.

with a

wooden

mallet;

this will relieve any

pressure

of

the

bearings on

the

end

of

the

journals. Before

replaci ng

the

sliding jolnt on

the

shaft,

thread

onto

the

splined shaft

the

dust

cover,

the

steel

washer

and

the

felt washer.

When

assembling

the

sliding

jclnt

be

sure

that

the

trunn

ions in

the

sliding and fixed joints

are

in line.

That

is to say,

the

axis of

the

forked

yoke

"A"

must

be parallel to

that

of

the

forked

yoke"

B " and

the

axis of for ked

yoke"

C ..

must

be parallel to

the

axis of forked

yoke"

D " as shown

in Fig. G.6. This can be checked by observing

that

the

arrows

marked on

the

spllned sleeve yoke and

the

splined shaft

are

in line.

It is always advisable

to

replace

the

cork

gasket and

th e

gasket

ret

ainers on

the

spider

journ

als by means

of

the

tubular

drift

shown

in Fig. G.5. The

spider

journal

shoulders

should be shellacked

prior

to fitting

the

retainers, to

ensure

a

good

oil seal.

G.3

Wishvilles Classic

Automobile Library

Loading...

Loading...