----

----

-

-

_

.

~

.

_--

-- -E

LE£

TRICAL

EQUIP~IENT

N

Section

N.B

THE STARTER SWITCH

The

starter

switch is fitted on

the

engine side of

the

bulkhead and is

operated

by pulling

the

control knob

in

the

instrument

panel.

The

knob is connected

to

the

switch by means of a cable. At

the

back of t he

starter

switch

are

two

terminals. from

one

of which

two

cables are connected,

the

heavy

one

to

the

battery

and

the

other

to

the

ammeter.

from

the

second

terminal

a heavy cable is

taken

to

the

terminal on

the

commutator

end

bracket

of

the

starter.

When

the

starter

Is

operated,

the

rotatIon of

the

armature

screws

the

pinion along

the

sleeve

to

mesh

with

the

flywheel

teeth.

As soon as

the

engine

starts

firing, it will drive

the

flywheel f

aster

than

it is being

driven by

the

starter.

This will cause

the

pinion co

screw back along

the

sleeve and so

draw

out

of mesh

with

the

flywheel

teeth

. A pinion

restra

ining spring

is fitted

over

the

shaft

to

prevent

the

pinion from

being vibrated into mesh when

the

engine Is running

..

In

the

event

of

the

starter

drive being jammed In

mesh

wlth

the

flywheel, it can usually be freed by

turn

ing

the

starter

armature

by means of a

spanner

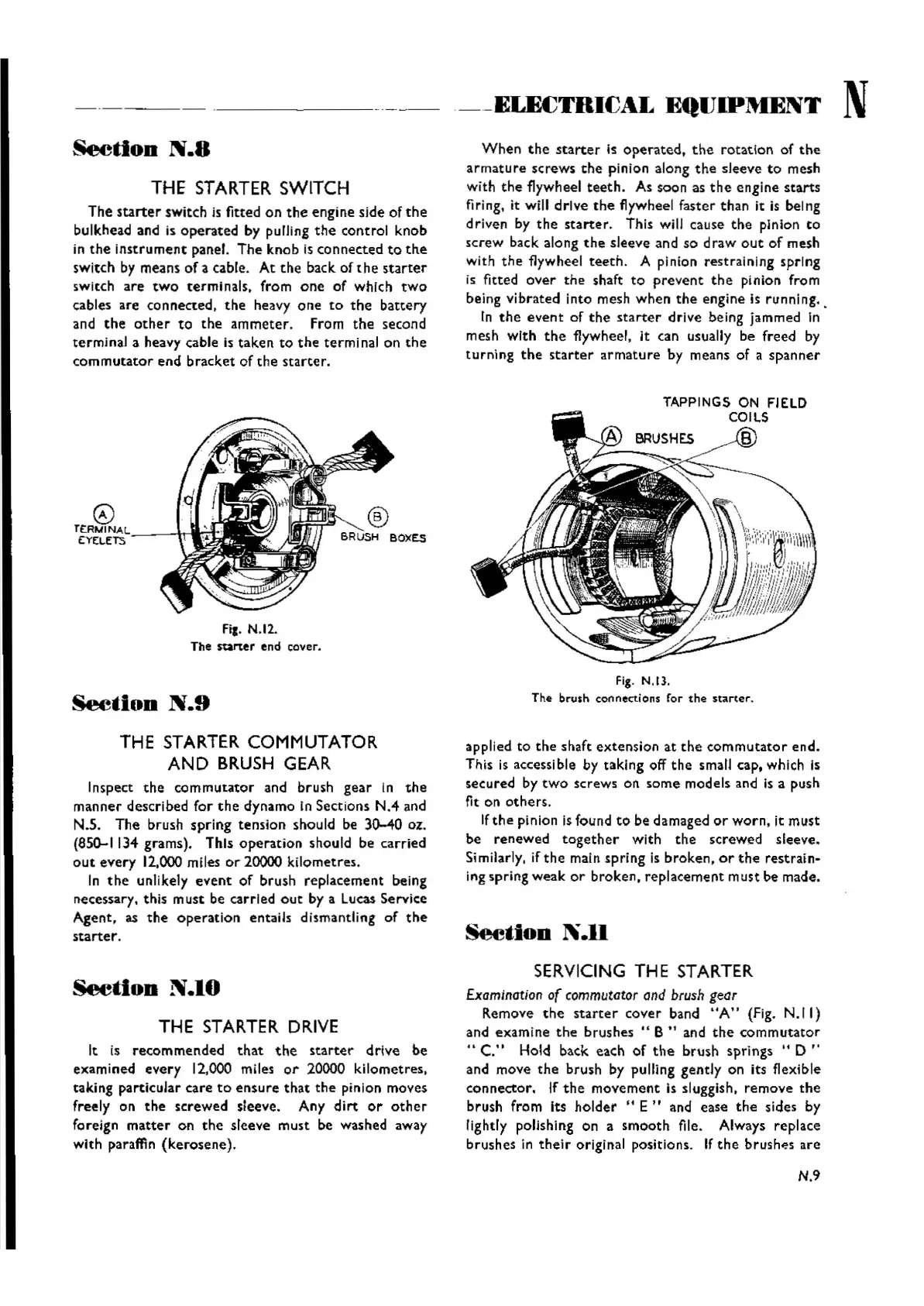

TAPPINGS ON FIELD

COILS

8

o

TeRMI

NAL

_ _

--\1ra::;'t:

C

YELETS

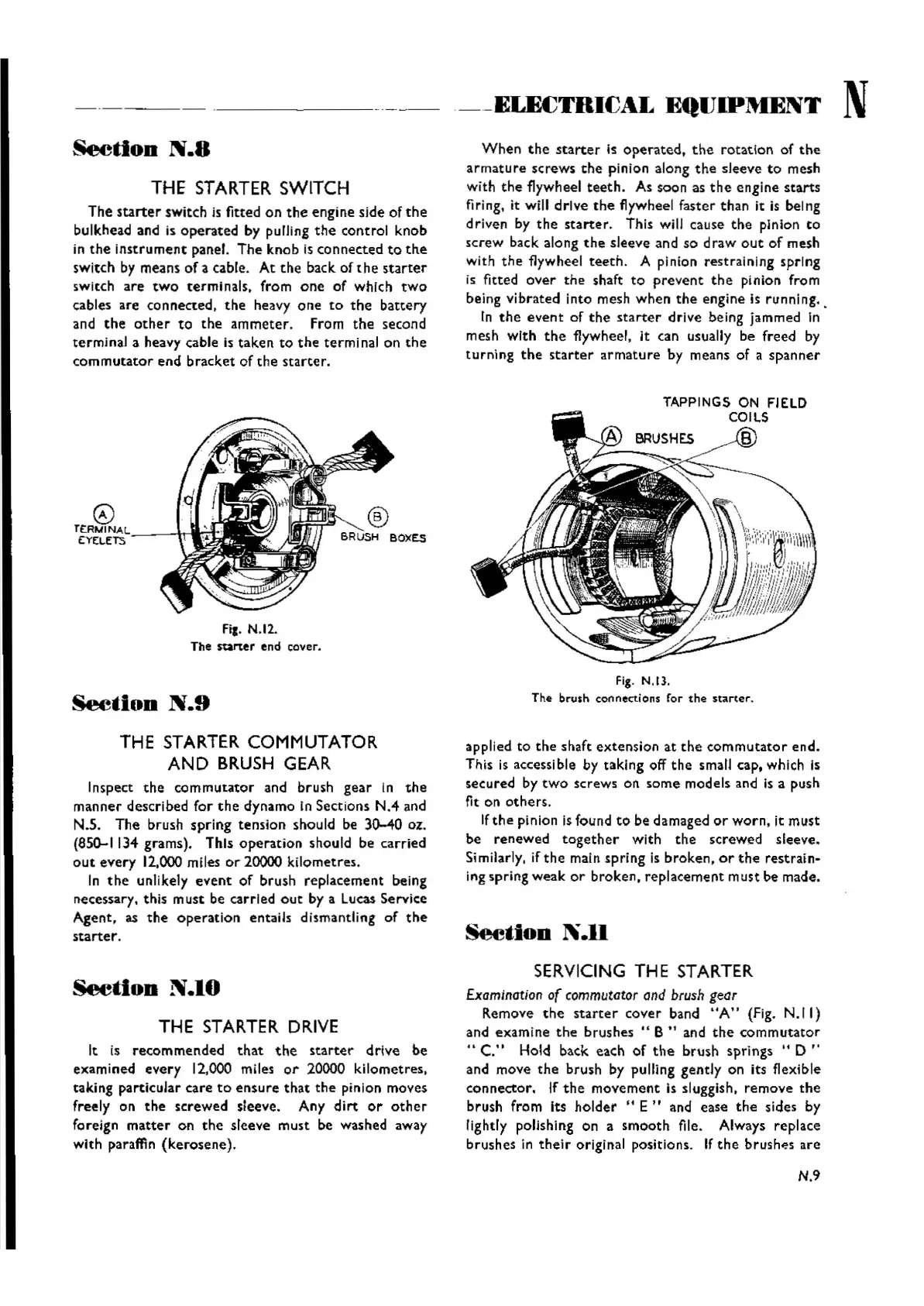

Fil. N.12.

The

starter

end

cover.

Section

N.9

Fig. N.13.

The brush connections Cor

the

starter.

THE STARTER

COMMUTATOR

AND

BRUSH GEAR

Inspect

the

commutator

and brush gear In

the

manner described for

the

dynamo In Sections

NA

and

N.S. The brush spring tension should be 30-40 oz.

(850--1134

grams). This

operation

should be carried

out

every

12.000

miles

or

20000 kilometres.

In

the

unlikely

event

of brush replacement being

necessary. this must be carried

out

by a Lucas Service

Agent, as

the

operation

entails dismantling of

the

starter

.

applied to

the

shaft extension at

the

commutator

end.

This is accessible

by taking off

the

small cap. which Is

secured by

two

screws on some models and is a push

fit

on

others.

If

the

pinion isfound

to

be damaged

or

worn,

it must

be renewed

together

with

the

screwed sleeve.

Similarly, if

the

main spring is

broken.

or

the

restrain-

ing spring weak

or

broken, replacement must be made.

Seetion

l\'.11

Section

N.IO

THE

STARTER

DRIVE

It is recommended

that

the

starter

drive be

examined every 12,000 miles

or

20000 kilometres.

taking particular care

to

ensure

that

the

pinion moves

freely on

the

screwed sleeve. Any

dirt

or

other

foreign

matter

on

the

sleeve

must

be washed away

With

paraffin

(kerosene).

SERVICING

THE STARTER

Examination

or

commutator

and b

rush

gear

Remove

the

starter

cover band

"A"

(Fig.

N.I

I)

and examine

the

brushes"

B " and

the

commutator

..

C."

Hold back each of

the

brush

springs"

D ,.

and move

the

brush by pulling gently on its flexible

connector.

If

the

movement

Is sluggish. remove

the

brush from Its

holder

"E"

and ease

the

sides by

lightly polishing on a

smooth

file. Always replace

brushes in

their

original positions. If

the

brushes

are

N.9

Wishvilles Classic

Automobile Library

Loading...

Loading...