A

THE

ENGINE----------------~-~

to

reassemble

the

main bearing shells

to

the

correct

bearings. 011 all

parts

with

clean oil

before

assembly.

Seetion

1\.34

REGRINDING THE CRANKSHAFT

If

the

crankshaft

journals

are

found

to

be

worn,

scored

or

oval.

they

must

be

reground

undersize

or

alternatively

the

engine

must

be

fitted

with

a

replacement

crankshaft.

The

table

on page A.21 gives details

of

the

various

sizes available

for

regrindIng

to

ensure

the

supply

of

bearings

to

match.

On

XPEG engi nes

the

crankshaft

cannot

be

reground

but

may be exchanged

for

a

new

one

(Part

No.

168557),

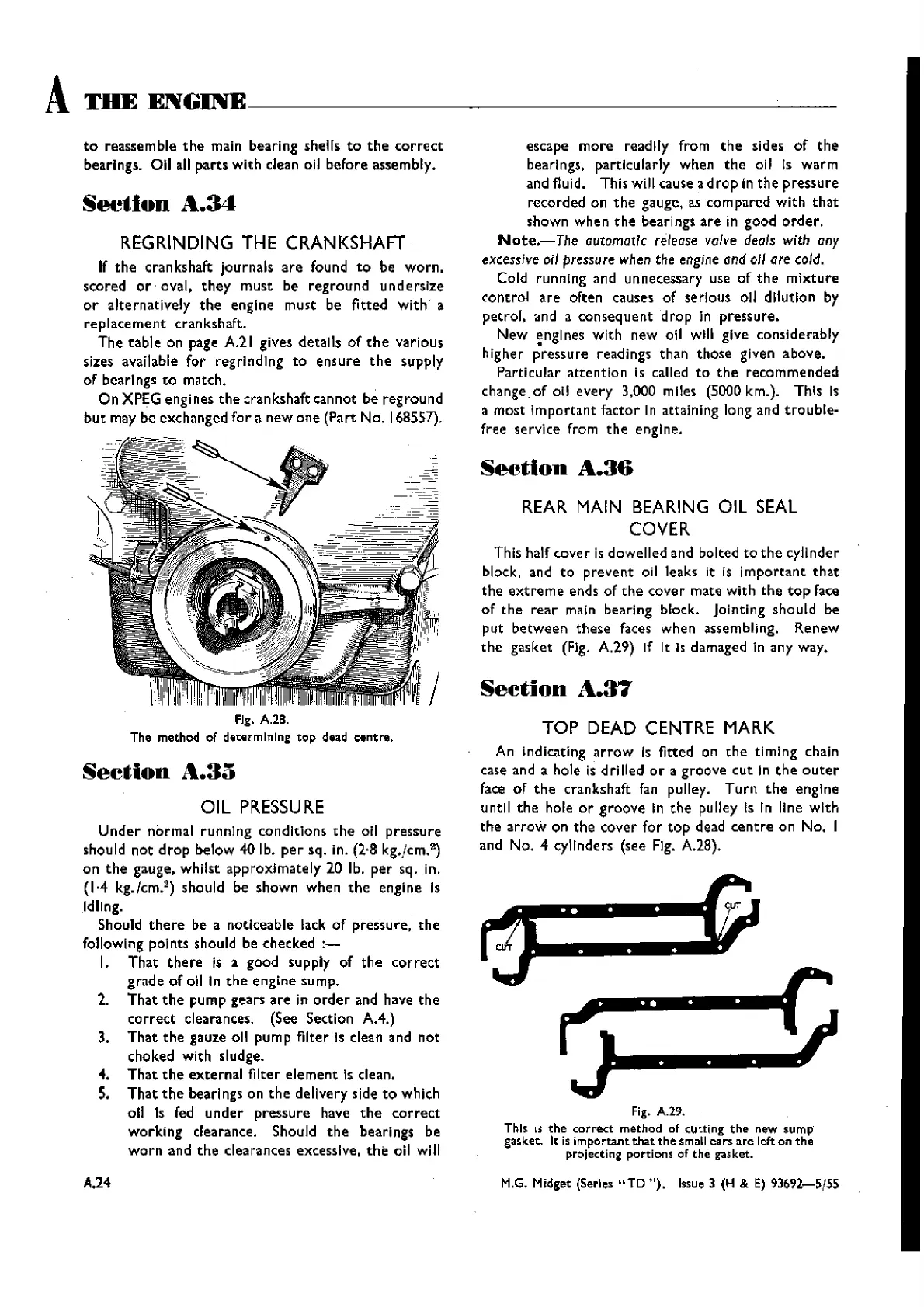

FIg. A.2B.

The method of

determining

top

dead

centre.

Section

A.35

OIL

PRESSURE

Under

normal

running

conditions

the

011

pressure

should

not

drop

below 40 lb.

per

sq. in. (2,8 kg./ern.

ll

)

on

the

gauge, whilst

approximately

20 lb.

per

sq. in.

(1·4 kg.

[cs».

2)

shouId be

shown

whe n

the

engi ne Is

Idling.

Should

there

be a noticeable lack

of

pressure.

the

following points should be checked

:-

I.

That

there

Is a good supply of

the

correct

grade

of

oil In

the

engine

sump.

2.

That

the

pump

gears

are

in

order

and have

the

correct

clearances. (See Section AA.)

3.

That

the

gauze all

pump

filter Is clean and

not

choked with sludge.

4.

That

the

external

filter

element

Is clean.

S.

That

the

bearings on

the

delivery side

to

which

oil Is fed

under

pressure

have

the

correct

working

clearance. Should

the

bearings be

worn

and

the

clearances excessive,

the

all will

A.24

escape

more

readily from

the

sides

of

the

bearings, particularly when

the

oil Is

warm

and fluid. This will cause

ad

rop

In

the

pressure

recorded

on

the

gauge, as

compared

with

that

shown

when

the

bearings

are

in

good

order.

Note.-The

automatic

release

valve deals with any

excessive oil pressure when the engine and

01/

are cold.

Cold running and unnecessary use

of

the

mixture

control

are

often causes

of

serious all dilution by

petrol,

and a

consequentd

rap

In

pressure.

New

;nglnes

with

new all wIll give considerably

higher

pressure

readings

than

those

given above.

Particular

attention

is called

to

the

recommended

change _

of

011

eve ry 3,000 miles (5000 km.). This Is

a

most

Important

factor

In attaining long and

trouble-

free service from

the

engi ne,

Section

A.36

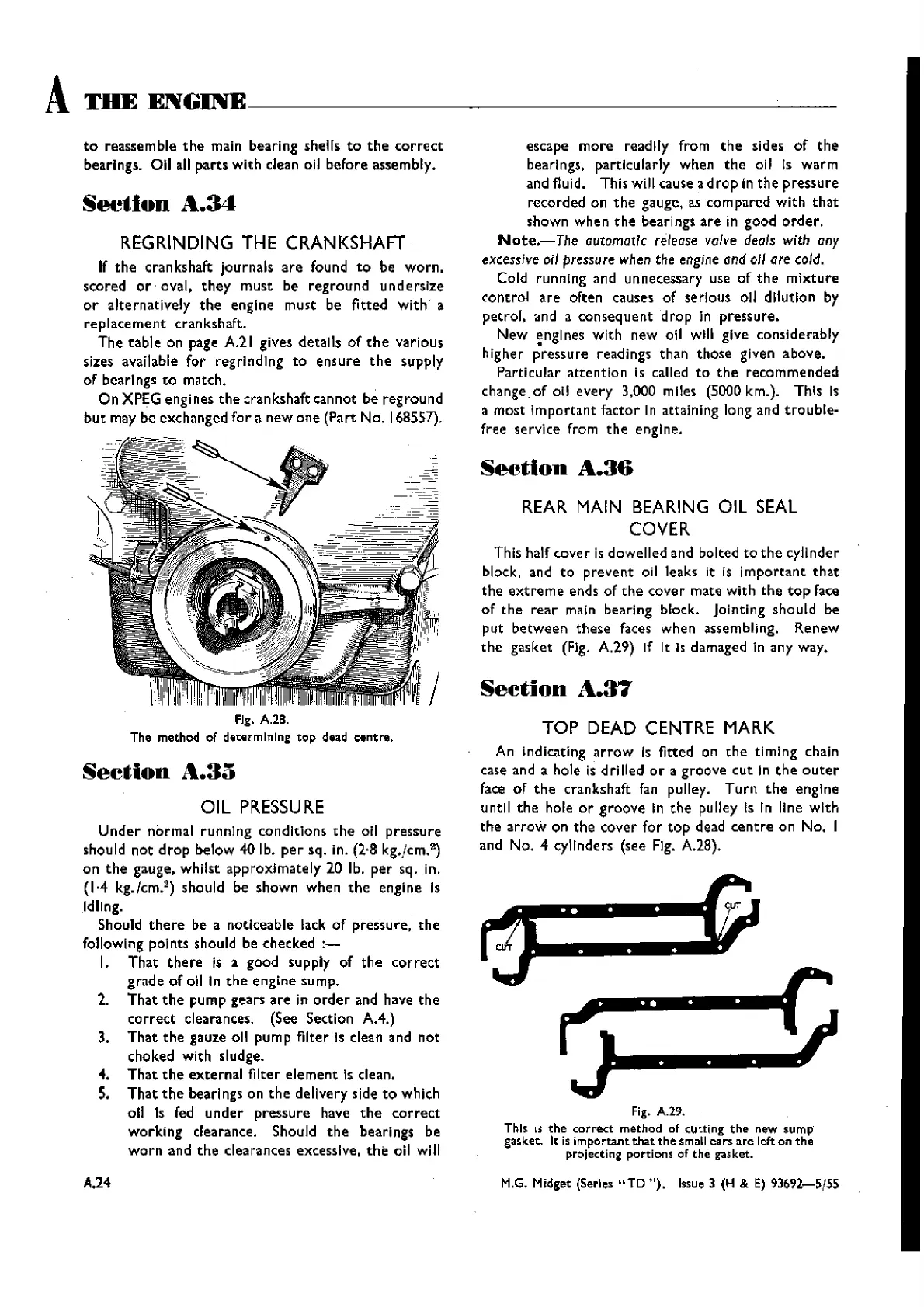

REAR MAIN BEARING OIL SEAL

COVER

This half

cover

is dowelled and bolted

to

the

cylinder

block, and

to

prevent

oil leaks it is

important

that

the

extreme

ends

of

the

cover

mate

with

the

top

face

of

the

rear

main bearing block. Jointing

should

be

put

between

these

faces when assembling.

Renew

the

gasket

(Fig. A.29) if It is damaged In any way.

Section

1\.37

TOP DEAD CENTRE MARK

An indicating

arrow

Is fitted on

the

timing

chain

case and

a hole is

drilled

or

a

groove

cut

In

the

outer

face

of

the

crankshaft fan pulley,

Turn

the

engine

until

the

hole

or

groove

in

the

pulley is in line

with

the

arrow

on

the

cover

for

top

dead

centre

on

No.

I

and

No.4

cylinders (see Fig. A.28).

..

.. . .

..

. .

..

Fig. A.29.

This

I.

the

correct

method

of cutting

the

new

sump

gasket. It is

important

that

the

small

ears

are

left on

the

projecting portions of the gasketo

M.G. Midget (Series

"TD

").

Issue 3 (H & E) 936'J2-5/55

Wishvilles Classic

Automobile Library

Loading...

Loading...