J

THE

STEERING GEAR

-------

----

--

.-

----~---------

Make

sure

that

the

oil

groove

is fitted

to

the

top

when

reaming.

Check

the

felt

washer

and

the

rubber

bellows and

renew

If necessary.

Examine

the

steering

rod balls and caps

for

wear

and

renew

as necessary

or

readjust

as

detailed

later.

Replacement

Is a reversal of

the

above

process.

Note.-When

rep/acing the

pinion

shaft see that the

thrust

washers

have their chamfered sides

towards

the

pInion.

End

float

should

be ·002 In.(OS mm.) to ·005 in.

(,13 mm.) and is

set

by

the shims.

The

oilway in

the

cap

should

be at

the

top

and

the

damper

pad must be

adjusted

as

detailed

under

J.7.

With

the

rack

in

the

central

position

engage

the

pinion

with

the

arrow

uppermost.

Refit

the

coupling

with

a coupling

bolt

In line

with

the

arrow

on

the

shaft. This will ensure

that

the

steering

wheel

spokes

are

in

the

correct

position

In

the

car.

011 all

parts

before

reassembling and refill

the

box

with

-i-

pint

(,4

litre)

of

lubricant

as specified on

page

P.2 (Ref.

B).

Soodon

J.6

ADJUSTMENT OF THE

INNER

STEERING

BALL

JOINT

Fit

the

lock

plate

and shims and

screw

home

the

ball

seat

housing

into

the

rack

bar.

Insert

the

ball

seat.

Screw

the

ball cap

home

against its

shoulder

after

In

sertl

ng

the

bail-a nded tie-

rod.

The ball

sho

uld have

no play,

but

must

be a

free

roll i

ng

f t, Ad justm

ent

can

be

altered

by varying

the

shims, which

are

supplied In

·003 In. ('08

mm.)

and ·005 in.

(,13

rnm.) slzes,

Section

J.':

ADJUSTMENT OF

THE

RACK

DAMPER

This is

provided

to

ensure

the

required

amount

of

damping

In

the

steering

tie-rods,

and

to

maintain

the

minimum

of

backlash in

the

gear

teeth.

This

should

_be

adjusted

in

the

followlng

manner

:-

Check

the

damper

spring, which

should

have a free

length

of

approximately

1·024 in. (26'01 mrn.), and

should

give a load

of

80 lb. (36,3 kg.)

when

compressed

to

·75 in. (19,05

mm.).

When

the

steering

gearbox

is

completely

assembled,

fit

the

plunger,

spring

and cap,

but

omit

the

shims.

Screw

down

the

cap until

the

plunger

bottoms.

While

screwing

down

the

plunger

rotate

the

pinion

shaft.

When

it is felt

to

just lock

the

rack bar In

the

houslng t he pl

unger

has

bottomed.

With

fee

ler

gauges

take

a

measurement

of

the

gap

left

and add

to

this

measurement

·051 in. (1·30 rnrn.].

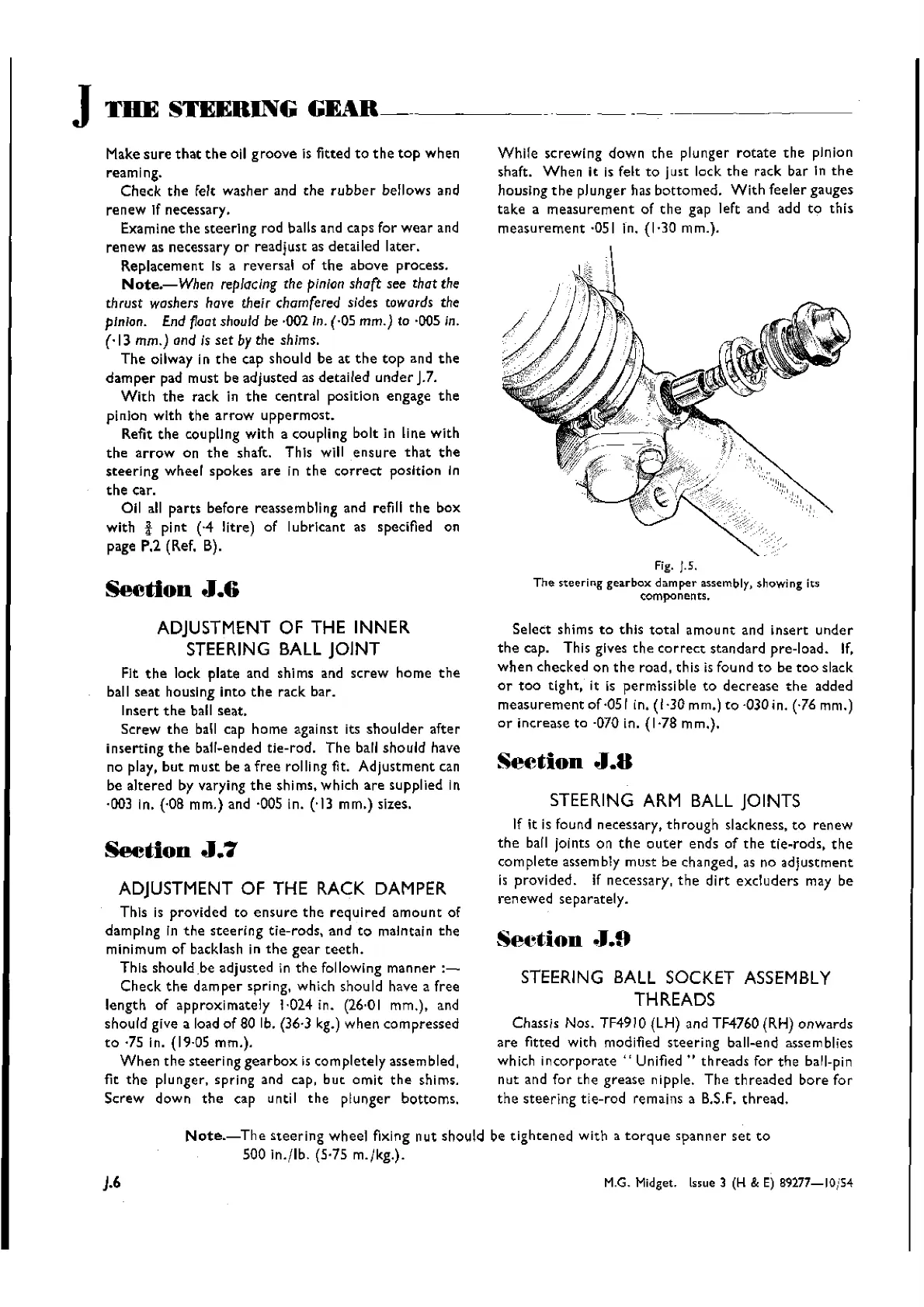

Fig. ).5.

The steering gearbox damper assembly, showing its

components.

Select

shims

to

this

total

amou

nt

and

insert

under

the

cap. This gives

the

correct

standard

pre-load.

If,

when

checked

on

the

road, th is is fou nd

to

be

too

slack

or

too

tight,

it is

permissible

to

decrease

the

added

measurement

of

·05 I in. (1,30

rnrn.]

to

·030 in. (·76 mm.)

or

increase

to ·070 in. (1'78 rnrn.},

Section

J.B

STEERING ARM BALL JOINTS

If it is found necessary,

through

slackness,

to

renew

the

ball joints on

the

outer

ends

of

the

tie-rods,

the

complete

assembly

must

be changed, as no

adjustment

is

provided.

If necessary,

the

dirt

excluders

may be

renewed

separately.

Set~tion

.1.9

STEERING

BALL

SOCKET ASSEMBLY

THREADS

Chassis Nos.

TF49

10(LH) and TF4760

(R.H)

onwards

are

fitted

with

modified

steering

ball-end assemblies

which

incorporate"

Unified"

threads

for

the

ball-pin

nut

and

for

the

grease

nipple.

The

threaded

bore

for

the

steering

tie-rod

remains a B.S.F.

thread,

).6

Note.-The

steering

wheel

fixing

nut

should

be

tightened

with

a

torque

spanner

set

to

500

in.jlb.

(5,75 rn.rkg.).

M.G. Midget. issue 3 (H & E)

89277-10/54

Wishvilles Classic

Automobile Library

Loading...

Loading...