BTHE FUEL

SYSTEM~---------------

faU

to

break,

it is possible

that

there

is

either

an

obstruction

in

the

suction

pipe, which should be

cleared by blowing it

through

with

air,

or

some

Irregularity

in

the

pu mp itself is

preventing

the

correct

movement.

This may be

due

either

to

the

diaphragm

havlng stiffened,

or

to

foreign

matter

in

the

roller

assembly which

supports

the

diaphragm, in which

case

the

diaphragm

should

be

removed

and

the

whole

assembly cleaned and reassembled In

accordance

with

the

instructions

in Section

B.4.

On

the

other

hand, if

the

points

are

not

making

contact,

see

that

the

tips

of

the

inner

rocker

(25)

are

in

contact

with

the

magnet

housing. If

they

are

not

it Is an indication

that

the

armature

has failed

to

return

to

the

end

of

its

normal

travel.

To

cure

this,

loosen

the

six

screws

which

attach

the

magnet

housing

to

the

pump

body, and

make

sure

that

the

diaphragm Is

not

sticking

to

the

face

of

the

magnet

housing by carefully passing a penknife

between

the

two,

The

hinge pin

(19)

should

then

be

removed

and

the

six

retaining

screws

tightened

up again

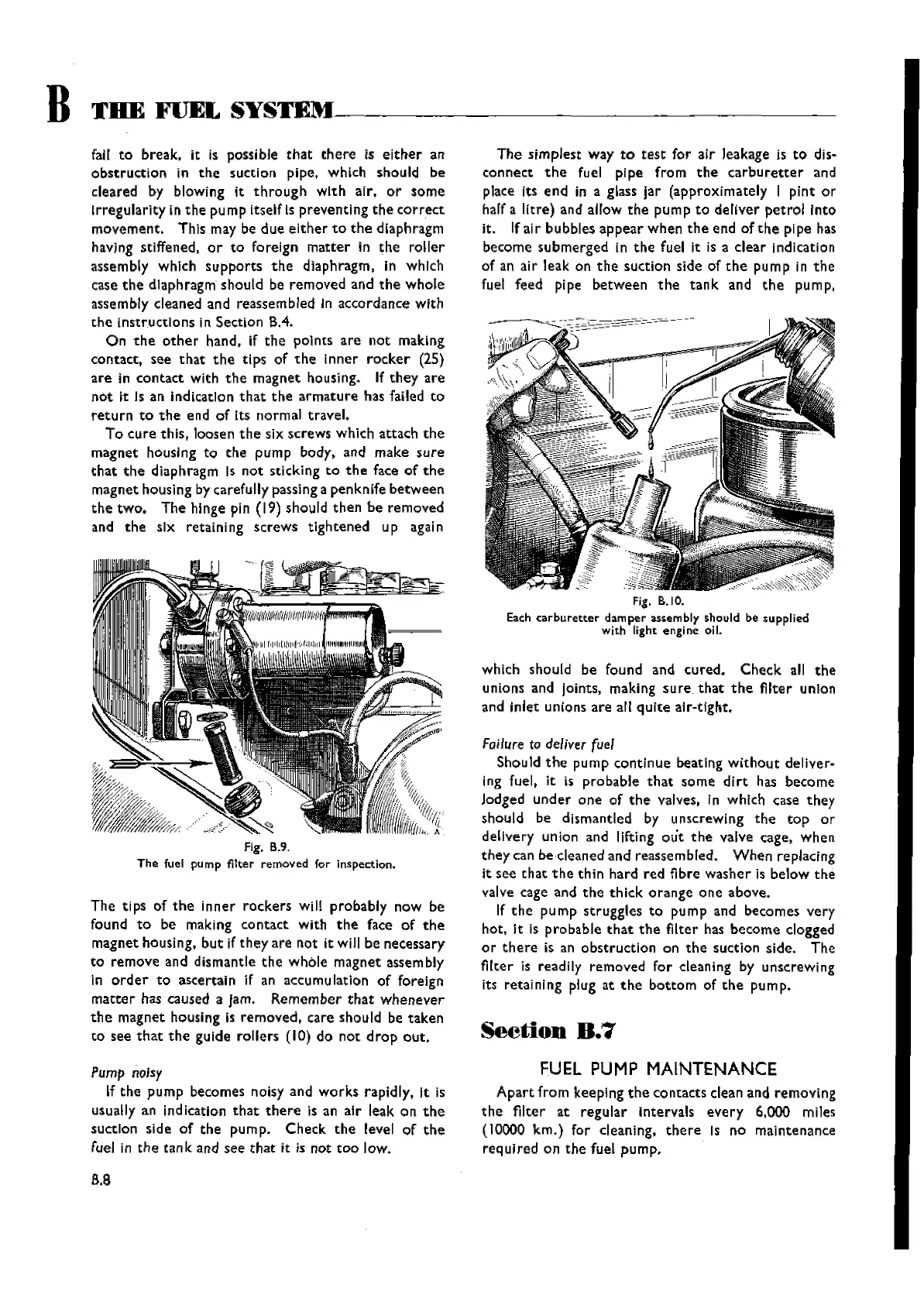

Fig. B.9.

The fuel pump filter removed for inspection.

The

tips

of

the

inner

rockers

will

probably

now

be

found

to

be making

contact

with

the

face

of

the

magnet

housing,

but

if

they

are

not

it will be necessary

to

remove

and dismantle

the

whole

magnet

assembly

in

order

to

ascertain

if an accumulation

of

foreign

matter

has caused a jam.

Remember

that

whenever

the

magnet

housing is

removed,

care

should be

taken

to

see

that

the

guide

rollers

(10) do

not

drop

out.

Pump

noisy

If

the

pump

becomes noisy and

works

rapidly, it is

usually an ind

lcatlon

that

there

is an alr leak 0 n

the

suction

side

of

the

pump.

Check

the

level

of

the

fuel in

the

tank

and

see

that

it is

not

too

low.

8,8

The

simplest

way

to

test

for

air

leakage is

to

dis-

connect

the

fuel

pipe

from

the

carburetter

and

place its

end

in a glass Jar

(approximately

I

pint

or

half a

litre)

and allow

the

pump

to

deliver

petrol

Into

it. If air

bubbles

appear

when

the

end of

the

pipe has

become

submerged

in

the

fuel it is a

clear

indication

of an air leak on

the

suction

side of

the

pump

in

the

fuel feed pipe

between

the

tank

and

the

pump,

which should be found and

cured.

Check

all

the

unions and Joints, making su re

that

the

filter

union

and

inlet

unions

are

all

quite

air-tight.

Failure

to deliver fuel

Should

the

pump

continue

beating

without

deliver-

ing fuel, it is

probable

that

some

dirt

has

become

lodged

under

one

of

the

valves, In which case

they

should

be

dismantled

by unscrewing

the

top

or

delivery union and lifting

out

the

valve cage,

when

they

can be cleaned

and

reassembled.

When

replacing

it see

that

the

thin

hard

red

fibre

washer

is

below

the

valve cage and

the

thick

orange

one

above.

If

the

pump

struggles

to

pump

and

becomes

very

hot, It is

probable

that

the

filter has

become

clogged

or

there

is an

obstruction

on

the

suction

side.

The

filter

is readily

removed

for

deaning

by unscrewlng

its

retaining

plug at

the

bottom

of

the

pump.

Section

8.7

FUEL

PUMP

MAINTENANCE

Apart

from

keeping

the

contacts

clean and

removing

the

filter

at

regular

intervals

every

6,000 miles

(10000

km.)

for cIeani ng,

the

re

Is no mai

nte

nance

required

on

the

fuel

pump.

Wishvilles Classic

Automobile Library

Loading...

Loading...