----------

-

------ELECTRICAL

EQUIPMENT

N

§ HA 0 PRESS

~

::::::

=:::::;

~

SHOULDERED

MANDREL

Reassembly

In

the

main

the

reassembly of

the

dynamo is a

reversal of

the

operations

described In Section N.4.

Before refitting

the

dynamo

to

the

vehicle, unscrew

the

Iubricatorfrom

the

com

mutator

end

bracket,

I

lft

out

the

felt

wick and

spring

and half

fill

the

cap with high-

melting-point grease

to

Ref. 0 (page P.2). Replace

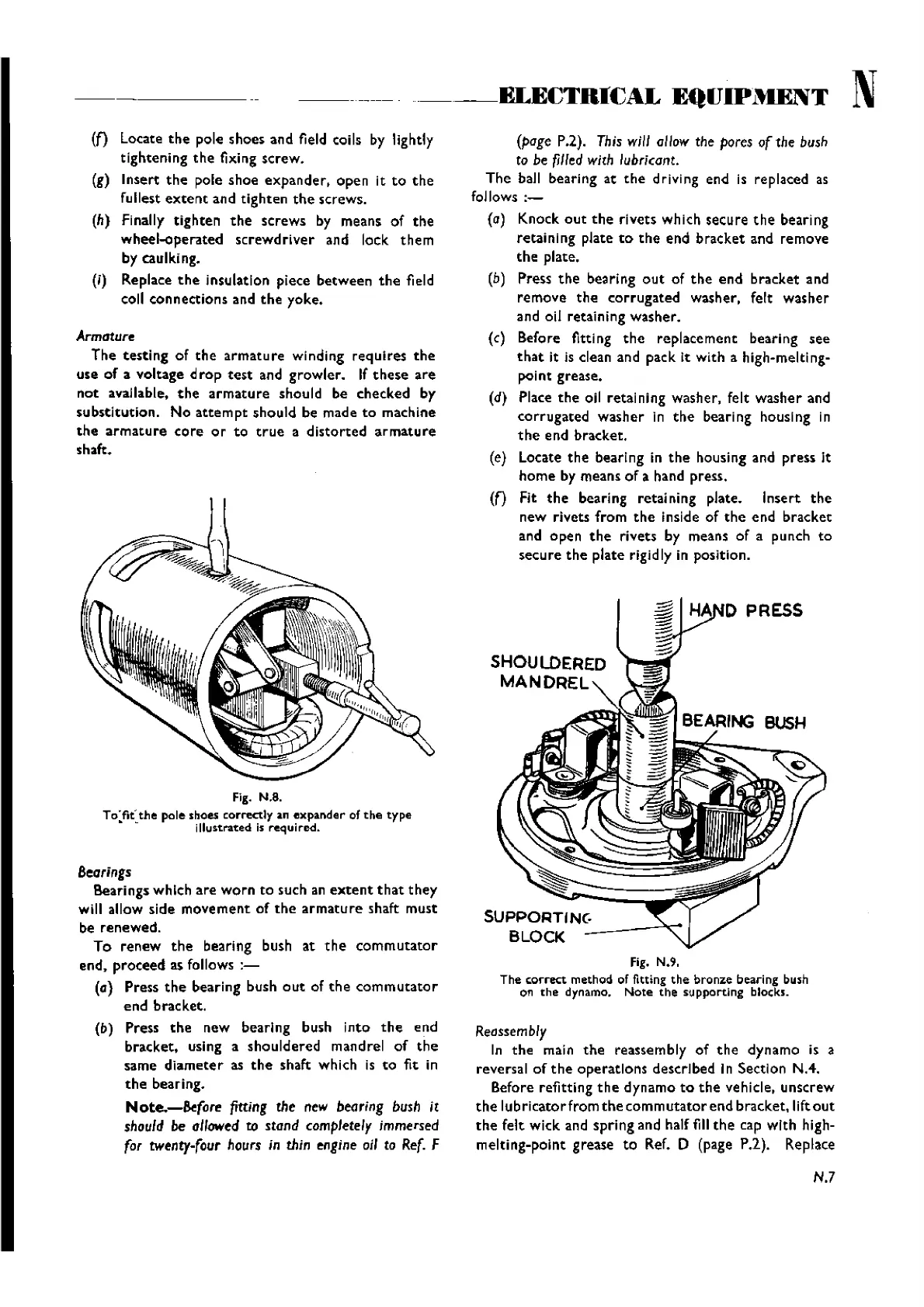

SUPPORTINf,.

BLOCK

---~

fig. N.9.

The

correct

method of fitting

the

bronze

bearing bush

on

the

dynamo.

Note

the

supportlrog blocks.

(page P.2). This will allow the

pores

ofthe bush

to be

filled

with lubricant.

The

ball bearing at

the

driving end is replaced as

follows

:-

(0) Knock

out

the

rivets

which

secure

the

bearing

retaining plate

to

the

end

bracket

and remove

the

plate.

(b)

Press

the

bearing

out

of

the

end

bracket

and

remove

the

corrugated

washer, felt

washer

and oil retaining

washer.

(c) Before fitti ng

the

replacement

bearing

see

t hat it is clean and pack It with a high-melti ng-

point grease.

(d) Place

the

oil retaining washer, felt

washer

and

corrugated

washer

in

the

bearing housing in

the

end bracket.

(e) Locate

the

bearing in

the

housing and press It

home

by means

of

a hand press.

(D Fit

the

bearing retaining plate.

Insert

the

new

rivets

from

the

Inside of

the

end

bracket

and

open

the

rivets by means of a punch

to

secure

the

plate rigidly in position.

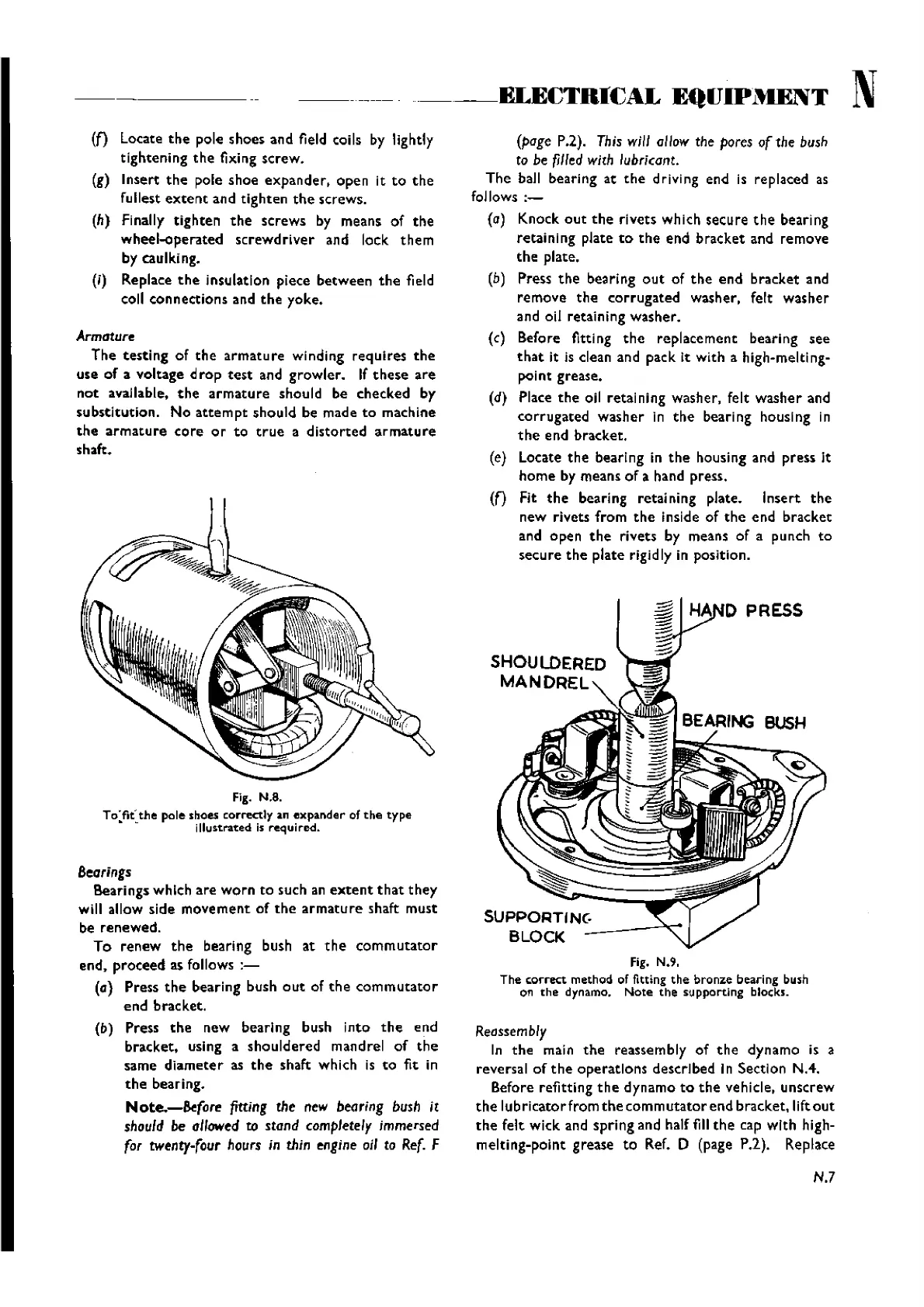

fig. N.S.

To~fi(

the

pole shoes correctly an expander- of

the

type

illustrated is

required.

(D Locate

the

pole shoes and field coils by lightly

tightening

the

fixing

screw.

(g) Insert

the

pole

shoe

expander,

open it

to

the

fullest

extent

and

tighten

the

screws.

(h) Finally

tighten

the

screws by means of

the

wheel-operated

screwdriver

and lock

them

by caulking.

(j) Replace

the

insulation piece

between

the

field

call connections and

the

yoke.

8earings

Bearings which

are

worn

to

such an

extent

that

they

will allow side

movement

of

the

armature

shaft must

be

renewed.

To

renew

the

bearing bush at

the

commutator

end.

proceed

as follows

:-

(a) Press

the

bearing bush

out

of

the

commutator

end

bracket.

(b) Press

the

new bearing bush

into

the

end

bracket.

using a

shouldered

mandrel of

the

same

diameter

as

the

shaft which is

to

fit in

the

bearing.

Note.-Before fitting the

new

bearing bush it

should

be

allowed

to stand completely immersed

for twenty-four hours in thin engine oil to Ref. F

Armature

The

testing

of

the

armature

winding

requires

the

use of a voltage

drop

test

and

growler.

If

these

are

not

available.

the

armature

should be checked by

substitution.

No

attempt

should be made

to

machine

the

armature

core

or

to

true

a

distorted

armature

shaft.

N.7

Wishvilles Classic

Automobile Library

Loading...

Loading...