M

THE

BRAKING

SYSTEM---------------

MAINTENANCE

Periodically examine

the

quantity of

brake

fluid in

the

master

cylinder. It should

never

be less

than

half

full

or

closer

than

tin.

(13 mm.) from

the

bottom

of

the

filler neck.

The

necessity for freq

uent

topping

up is an Indication of over-filllng

or

a leak in

the

system. which should at

once

be

traced

and rectified.

Adjust

the

brake-shoes

to

compensate

for

wear

of

the

linings.

The

need for

this

is shown by

the

pedal

going

down

almost

to

the

floorboards before solid

resistance is felt. For brake-shoe

adjustments

see

Section

M.2.

Adjustment

of

the

brake-shoes In

the

manner

Indicated also adjusts

the

hand brake automatically

and no

separate

adjustment

is

required

or

permitted.

THE

MASTER

CYLINDER

The

master

cylinder is

mounted

on

the

driver's

side of

the

car

underneath

the

gearbox

cover.

Within

the

cylinder is a piston, backed by a

rubber

cup. normally held in

the"

off"

position by a piston

retu

rn spri ng. lrnmed late Iy in

front

of

the

cup.

when

it is In

the

..

off"

position, is a compensattng orifice

connecting

the

cylinder with

the

fluid supply. This

port

allows

free

compensation for any expansion

or

contraction

of

the

fluid,

thus

ensuring

that

the

system

is constantly

filled;

it also serves as a release

for

additional fluid drawn

into

the

system during brake

applications. Pressu re is applied

to

the

piston by

means of

the

push-rod attached

to

the

brake

pedal.

The push-rod is adjustable and should have a slight

clearance

when

the

system is at

rest

to allow

the

piston

to

return

fully against its

stop.

Without

thls

clearance ehe main cup will

cover

the

by-pass

port,

causing pressure

to

build up within

the

system. and

produce

binding of

the

brakes on all wheels.

The

reduced

skirt

of

the

piston forms an annular space

M.4

which is filled with fluid from

the

supply

tank

via

the

feed hole. Leakage of fluid from

the

open

end of

the

cylinder is

prevented

by

the

secondary cup fitted

to

the

flange end of

the

piston. On releasing

the

brake

pedal, afte r ap piicatio n,

the

pisto n is reeurned quickly

to its

stop

by

the

return

spring,

thus

creating a vacuum

in

the

cylinder;

this vacuum causes

the

main cup

to

collapse and pass fluid

through

the

small holes In

the

piston head from

the

annular space formed by

the

piston ski rt. This additional fluid finds Its way back.

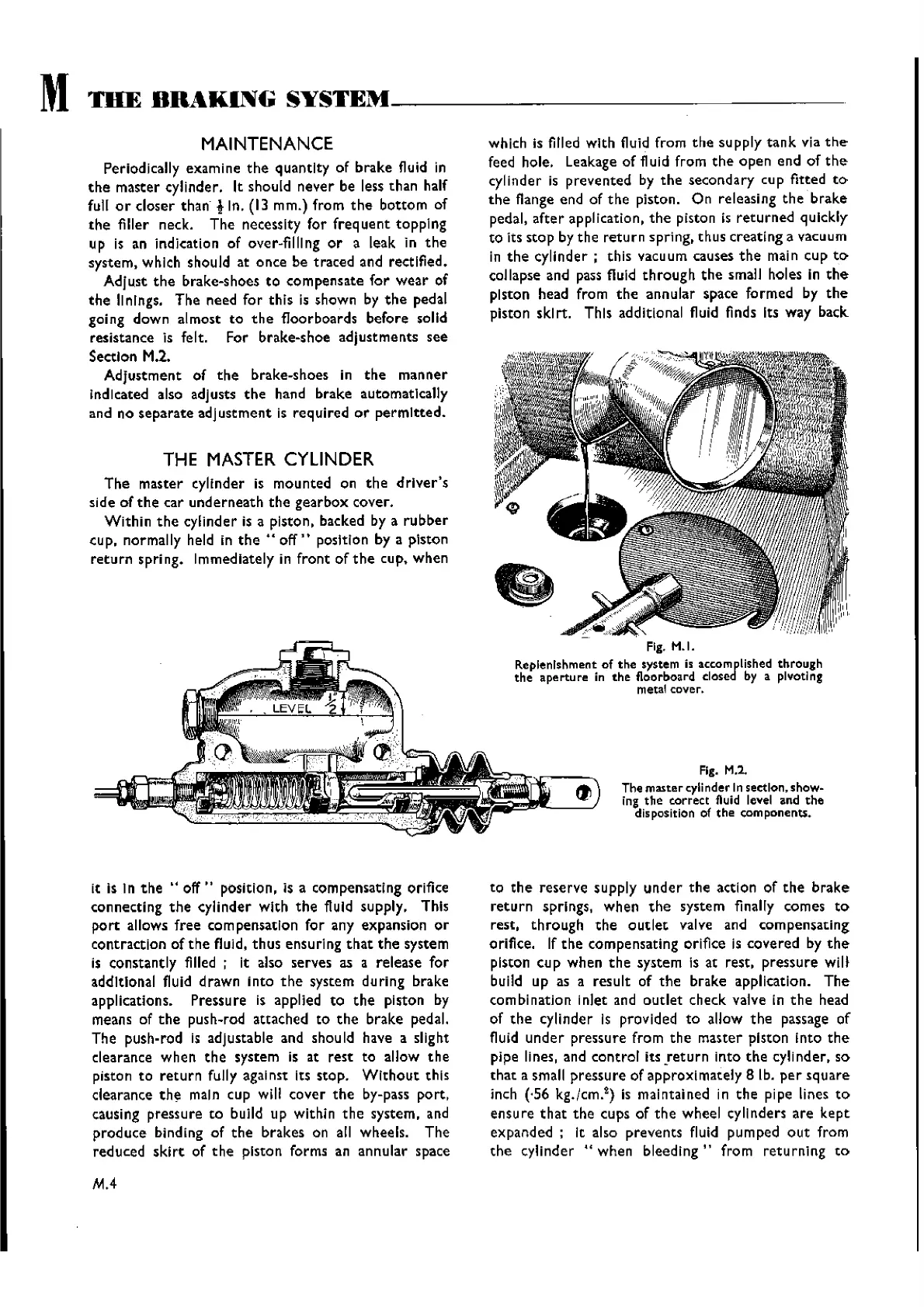

Fig.

H.I.

Replenishment of

the

system is accomplished

through

the

ape rtu re in

the

floorboard closed by a plvotl ng

metal cover.

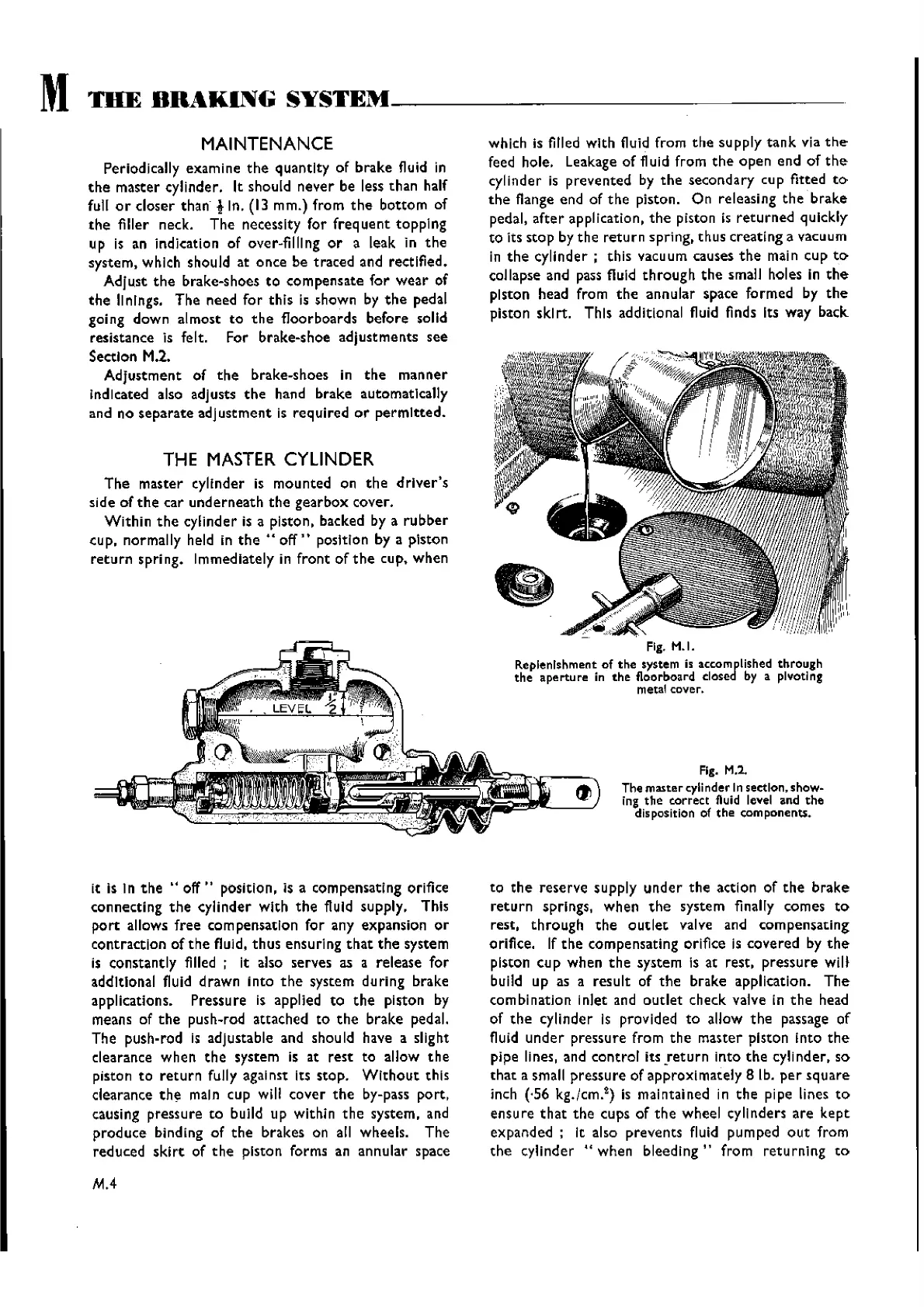

Fig.

M.l.

The

master

cylinder In section. show-

ing

the

correct fluid level and the

disposition of

the

components.

to

the

reserve

supply

under

the

action of

the

brake

return

springs.

when

the

system finally comes

to

rest,

through

the

outlet

valve and

compensating

orifice. If

the

compensating orifice is

covered

by

the

piston

cup

when

the

system Is at rest,

pressure

wil.

build up as a

result

of

the

brake application.

The

combination inlet and

outlet

check valve in

the

head

of

the

cylinder Is provided

to

allow

the

passage of

fluid

under

pressure from

the

master

piston

into

the

pipe lines, and

control

its

!eturn

into

the

cylinder, so

that

a small

pressure

of

apprcxlmately

8 lb.

per

square

inch (·56 kg./cm.

2

)

is maintained in

the

pipe lines

to

ensure

that

the

cups of

the

wheel cylinders

are

kept

expanded;

It also

prevents

fluid pumped

out

from

the

cylinder

"when

bleeding ,. from

returning

to

Wishvilles Classic

Automobile Library

Loading...

Loading...