A

TOE

ENGINE---~----------~

Section

A.IO

REMOVAL

AND

REPLACEMENT

OF

PISTONS

AND CONNECTING

RODS

Follow

the

dismantling

procedure

as

set

out

in

Section

A.7 and

withdraw

the

piston and

connecting

rod

assembly carefully past

the

crankshaft On

the

left-

hand side

of

the

engine,

rotating

the

crankshaft as

necessary

to

give

the

required

clearance.

Note.--:-It

/s essential that pistons be fitted in the same

bores as they were be(ore removaf. The gudgeon pin

pinch-bolt must be on the right-hand side o( the engine.

The

same connecting

rod

andcap,completewith bearings,

must befitted to the

jOu

rnaI (rom wh

ich

they were removed.

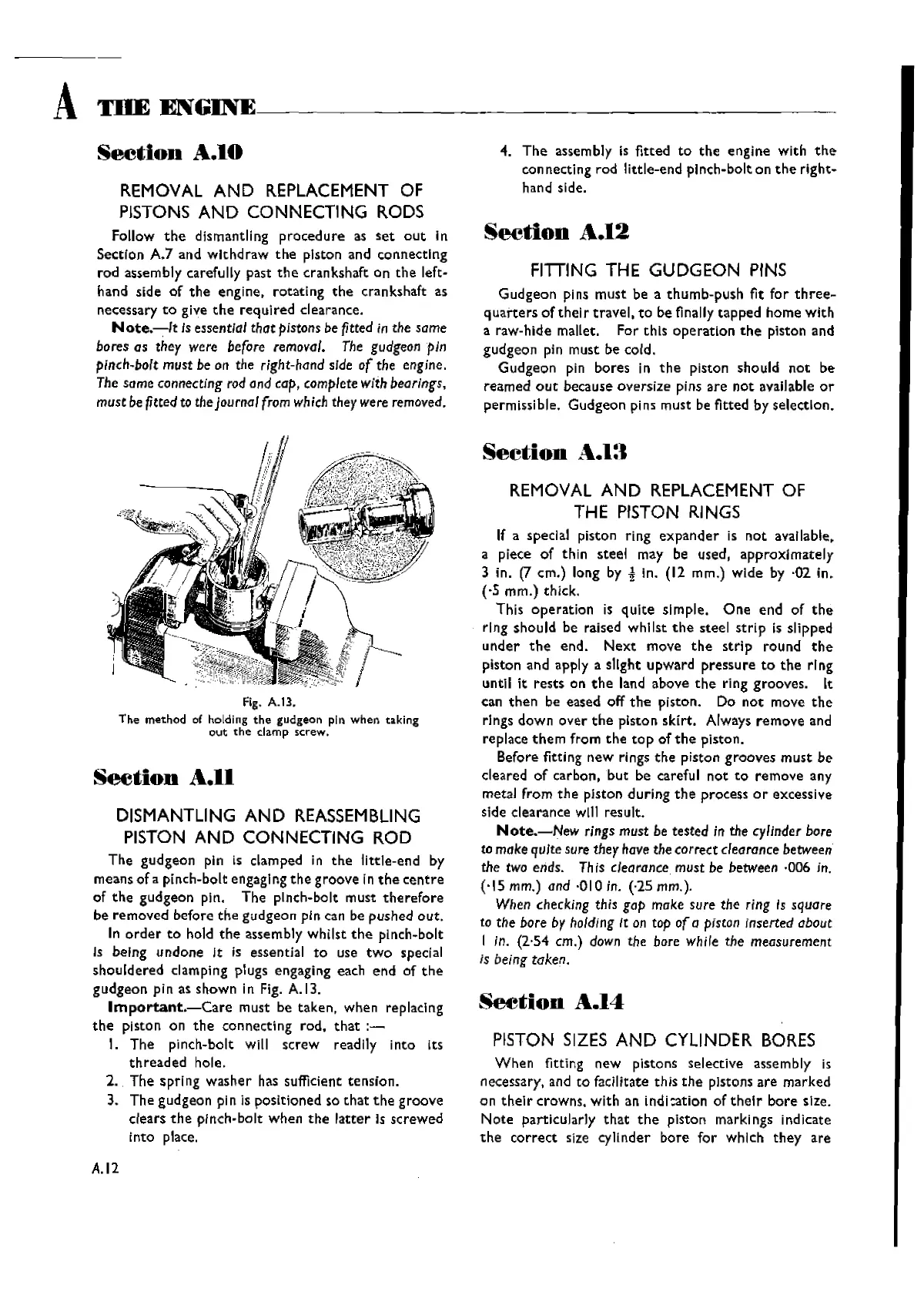

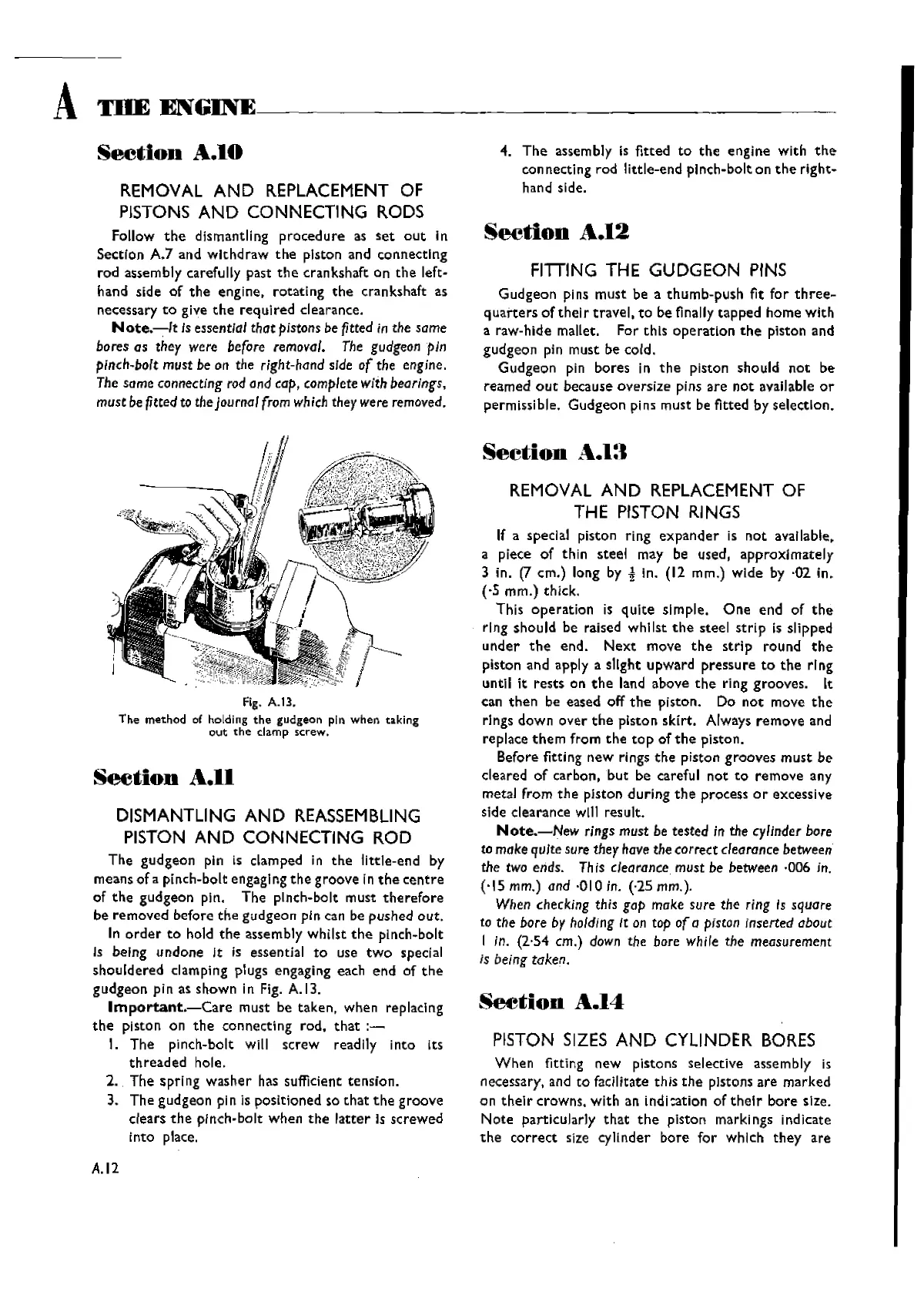

Fig.

A.B.

Tile method of

holding

tile gudgeon pin

when

taking

out

the

damp

screw.

See:tion

A.II

DISMANTLING

AND

REASSEMBLING

PISTON

AND CONNECTING ROD

The

gudgeon

pin is clamped in

the

little-end

by

means

of

a pinch-bolt engagi ng

the

groove

in

the

centre

of

the

gudgeon

pin.

The

pinch-bolt must

therefore

be

removed

before

the

gudgeon

pin can be

pushed

out.

In

order

to

hold

the

assembly

whilst

the

pinch-bolt

Is being

undone

It Is essential

to

use

two

special

shouldered

clamping plugs engaging each

end

of

the

gudgeon

pin as

shown

in Fig. A.13.

Irnportant.-Care

must be

taken,

when replaclng

the

piston on

the

connecting

rod,

that

:-

I.

The

pinch-bolt will

screw

readily

into

Its

threaded

hole.

2.

The

spring

washer

has sufficient

tension.

3.

The

gudgeon

pin is

positioned

so

that

the

groove

dears

the

pinch-bolt

when

the

latter

Is

screwed

into

place.

A.12

4.

The

assembly is

fitted

to

the

engine

with

the

con necti ng

rod

I

ittle-end

pinch-bolt on

the

right-

hand side.

Seetion

A.12

FITTING

THE GUDGEON

PINS

Gudgeon

pins

must

be a

thumb-push

fit

for

three-

quarters

oftheir

travel,

to

be finally

tapped

home

with

a raw-hide mallet. For

this

operation

the

piston and

gudgeon

pin

must

be cold.

Gudgeon

pin

bores

in

the

piston should

not

be

reamed

out

because

oversize

pins

are

not

available

or

permissible.

Gudgeon

pins must be fitted by

selection.

Section

..

:\..1:1

REMOVAL

AND

REPLACEMENT

OF

THE

PISTON

RINGS

If a speclal piston ring

expander

is

not

available.

a piece

of

thin

steel

may be used,

approximately

3 in.

[T

crn.) long by i In. (12 mm.)

wide

by ·02

in.

(,5

mm.)

thick.

This

operation

is

quite

simple.

One

end

of

the

ring

should

be raised

whilst

the

steel

strip

is slipped

under

the

end.

Next

move

the

strip

round

the

piston and apply a slight

upward

pressure

to

the

ring

until it

rests

on

the

land above

the

ring

grooves.

It

can

then

be eased off

the

piston. Do

not

move

the

rings

down

over

the

piston

skirt.

Always

remove

and

replace

them

from

the

top

of

the

piston.

Before fitting

new

rings

the

piston

grooves

must

be

cleared

of

carbon,

but

be careful

not

to

remove

any

metal

from

the

pIston

during

the

process

or

excessive

side clearance

will result.

Note.-New

rings must be tested in the cylinder

bore

to make quite

sure

they havethe correct clearancebetween

the two ends. This clearance must be between ·006 in.

('15

mm.) and ·010 in. (·25 mm.).

When checking this gap make sure the ring Is

square

to the bore by holding

It

on top

of

a

piscon

inserted about

I in. (2'54 em.)

down

the bore

While

the measurement

is being taken.

Seetion

A.14

PISTON

SIZES

AND

CYLINDER

BORES

When

fitting

new

pistons selective assembly is

necessary, and

to

facilitate this

the

pIstons

are

marked

on

their

crowns.

with

an

indi:ation

of

their

bore

size.

N

ate

particularly

that

the

piston

marki ngs ind

kate

the

correct

size

cylinder

bore

for

which

they

are

Wishvilles Classic

Automobile Library

Loading...

Loading...