--------------THE

(;OOLING

SYSTEM

D

Take

out

the

set

bolts and

remove

the

pump unit

by breaking

the

[olnt

between

the

impeller housing

flange and

the

cylinder block. moving

the

inner

control

link

bracket

outwards

to

clear.

Dismantle

the

pump by removing

the

impeller from

the

shaft. tapping

out

the

taper

pin attaching it

to

the

shaft and taking care

to

see

that

it is knocked

out

in

the

right direction.

Withdraw

the

pressure

spring

and washer. which gives access to

the

carbon seal and

gland

washer

assembly.

Care

should be taken

not

to

damage

the

carbon ring. which is relatively

brittle,

the

working face of

the

rubber

seal, and

not

to

lose

of

the

spindle on a plec:e of

wood

until

the

outer

bearing can be

withdrawn.

This will release

the

distance-plece

between

the

bearings, which can be

withdrawn.

giving access

to

the

Inner race.

Remove

the

Inner

drclip

by

contracting

the

ring

and inserting a

screwdriver

behind it

to

ease It

out

of

its groove.

After

removal

of

the

clrdip

the

retaining

bearing and

the

impeller spindle can be

withdrawn.

If

the

felt

011

sealing rings

are

badly

worn

or

the

bearings unduly slack,

they

should be

renewed.

Care-

fully examine

the

carbon

sealing ring

for

cracks

or

undue

wear

and

renew

if necessary. The face of

the

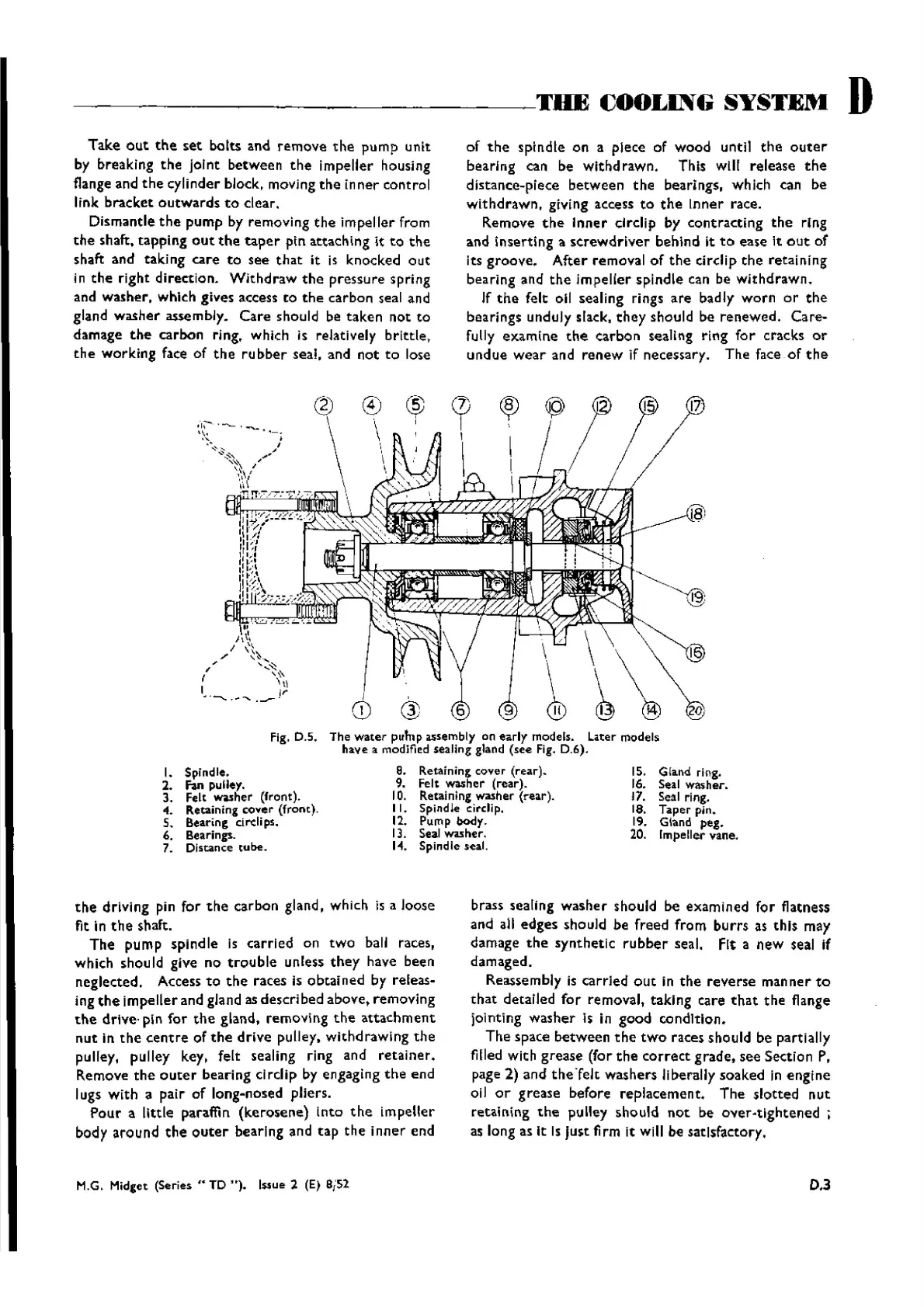

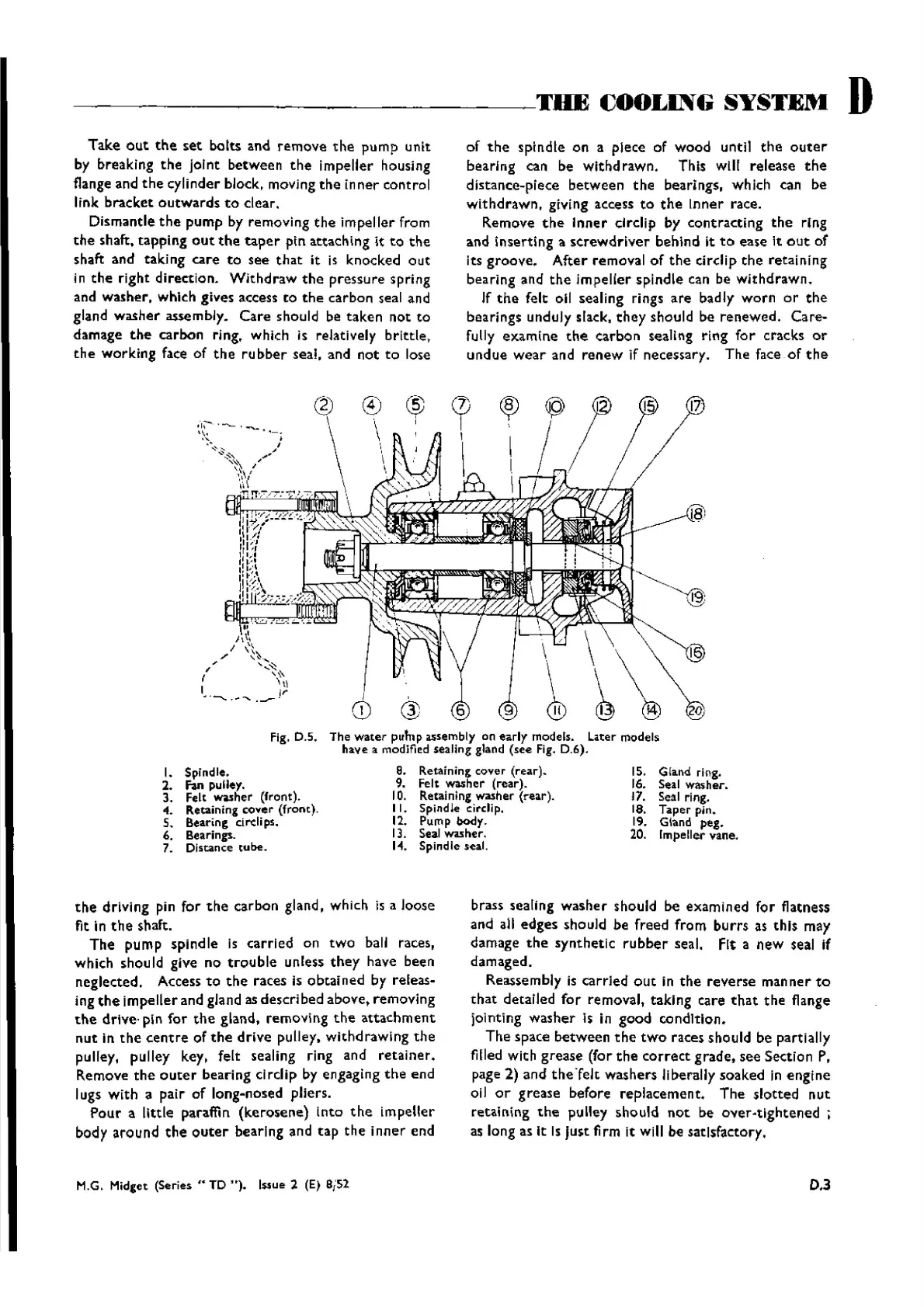

15. Gland ring.

16. Seal washer.

17. Seal

ring.

18. Taper pin.

19.

Gland peg.

20. Impeller vane.

fig. D.S.

I. Spindle .

2.

Fan

pulley.

3.

felt

~her

(front).

4. Retaining

cover

(front).

5.

Bearing clreli ps.

6.

Bearings.

7. Distance tube.

\ \ \ \

®

~

'@

The

water

pump

usembly

on

early

models.

later

models

have

a modified sealing gland (see Fig. D.6).

8. Retaining

c:ov

er (r

ear).

9. Felt washer (rear).

10. Retaining wasner

(rear)

.

II.

Spindle c:irdip.

12. Pump

body.

13. Seal

washer.

14. Spindle seal.

17

o

the

driving pin for

the

carbon gland, which is a loose

fit

in

the

shaft.

The

pump spindle is carried on

two

ball races,

which should give no

trouble

unless

they

have been

neglected. Access

to

the

races is

obtained

by releas-

ing

the

impe ller and gland as descrlbed above, removing

the

drive· pin

for

the

gland. removing

the

attachment

nut

in

the

centre

of

the

drive

pulley.

withdrawing

the

pulley, pulley key. felt sealing ring and

retainer.

Remove

the

outer

bearing c1rcllp by engaging

the

end

lugs

with

a pair of long-nosed pliers.

Pour

a little paraffin

(kerosene)

Into

the

impeller

body around

the

outer

bearing and

tap

the

inner

end

M.G. Midget (Series ,. TD

"],

lssue 2 (E) SiS

2

brass sealing washer should be exam ined for flatness

and all edges should be freed from

burrs

as

this

may

damage

the

synthetic

rubber

seal.

fit

a new seal If

damaged.

Reassembly is carried

out

in

the

reverse

manner

to

that

detailed for removal, taking care

that

the

flange

jointing

washer

Is in

good

condition.

The

space

between

the

two

races should be partially

filled with grease (for

the

correct

grade. see Section P.

page 2) and

thefelt

washers liberally soaked in

engine

oil

or

grease before replacement.

The

slotted

nut

retaining

the

pulley should

not

be

ever-tightened

;

as long as

it

Is Just firm it will be satisfactory.

D,3

Wishvilles Classic

Automobile Library

Loading...

Loading...