-

174

-

(iv) Refrigerant pipe

Caution

● Use the new refrigerant pipe.

When re-using the existing pipe system for R22 or R407C, pay attention to the following items.

• Change the flare nuts with the attached ones (JIS category 2), and reprocess the flare parts.

• Do not use thin-walled pipes.

● Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS H3300) for refrigeration pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no harmful substances such as sulfur,

oxide, dust or a contaminant stuck on the pipes.

● Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil. And air getting into refrigeration

circuit may cause over-pressure and resultant it may result in bursting, etc.

● Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any dust, dirt or water

getting into pipe. Otherwise it will cause degradation of refrigeration oil and compressor breakdown, etc.

● Use special tools for R410 refrigerant.

Work procedure

q Remove the flare nut and blind flanges on the pipe of the indoor unit.

❈ Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque to the nut with

another spanner in order to avoid unexpected stress to the copper pipe, and then remove them.

(Gas may come out at this time, but it is not abnormal.)

● Pay attention whether the flare nut pops out. (as the indoor unit is sometimes pressured.)

w Make a flare on liquid pipe and gas pipe, and connect the refrigeration pipes on the indoor unit.

❈ Bend the pipe with as big radius as possible and do not bend the pipe repeatedly. In addition, do not twist and crush the

pipes.

❈ Do a flare connection as follows:

● Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque to the nut with

another spanner in order to avoid unexpected stress to the copper pipe, and then remove them.

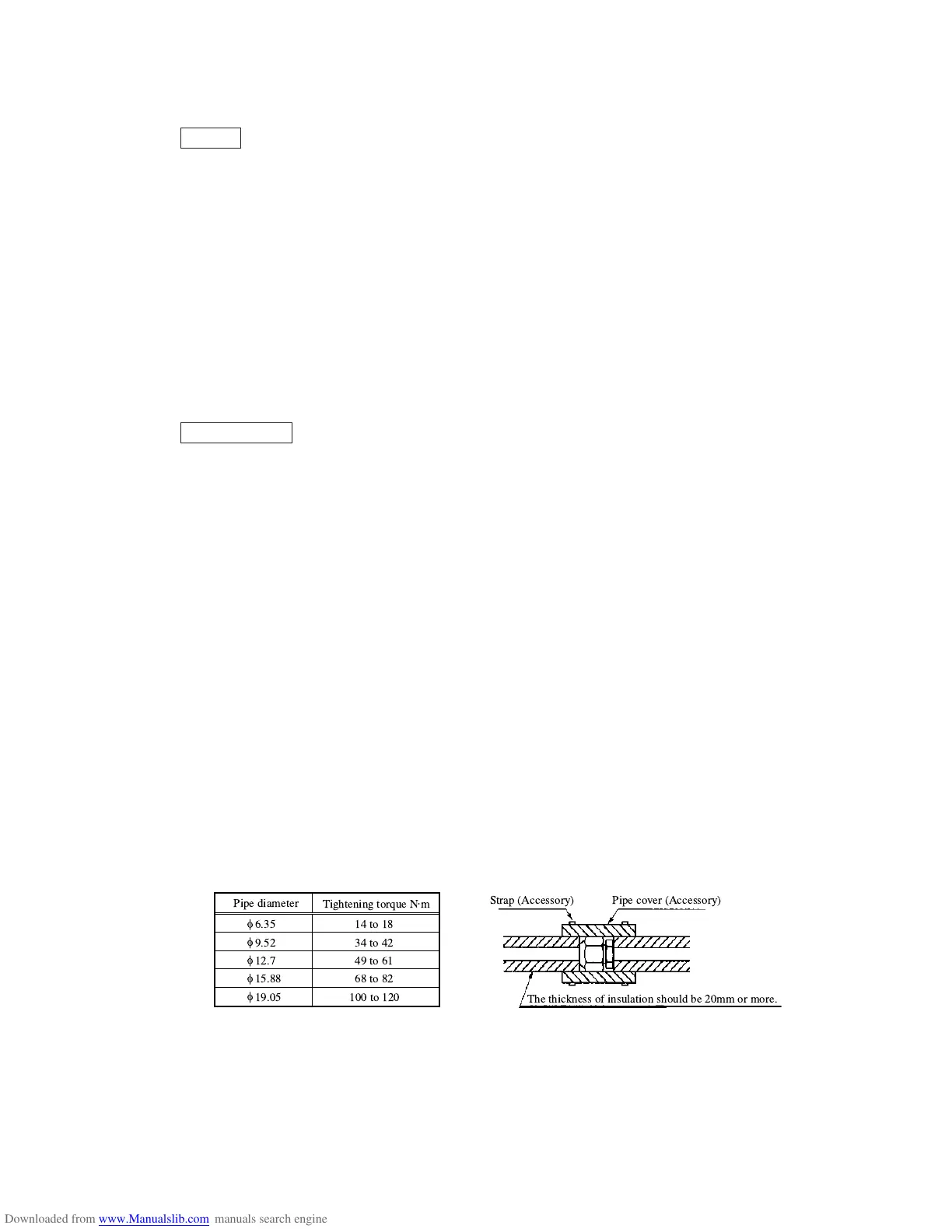

● When fastening the flare nut, align the refrigeration pipe with the center of flare nut, screw the nut for 3-4 times by hand

and then tighten it by spanner with the specified torque mentioned in the table below. Make sure to hold the pipe on the

indoor unit securely by a spanner when tightening the nut in order to avoid unexpected stress on the copper pipe.

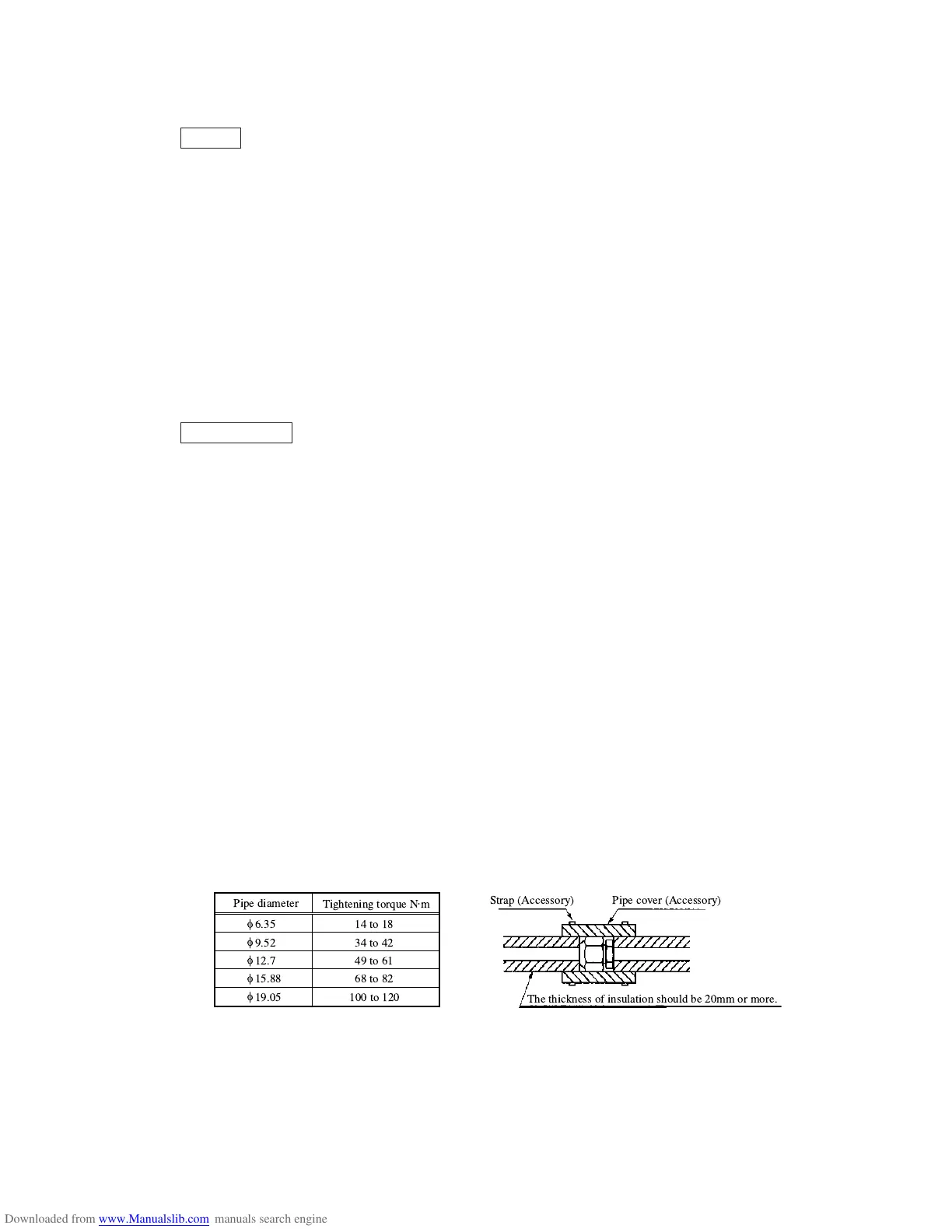

e Cover the flare connection part of the indoor unit with attached insulation material after a gas leakage inspection, and

tighten both ends with attached straps.

● Make sure to insulate both gas pipes and liquid pipes completely.

❈ Incomplete insulation may cause dew condensation or water dropping.

r Refrigerant is charged in the outdoor unit.

As for the additional refrigerant charge for the indoor unit and piping, refer to the installation manual attached to the

outdoor unit.

Strap (Accessory) Pipe cover (Accessory)

The thickness of insulation should be 20mm or more.

Pipe diameter

Tightening torque Nám

14 to 18

34 to 42

49 to 61

68 to 82

100 to 120

6.35

9.52

12.7

15.88

19.05

Loading...

Loading...