-

206

-

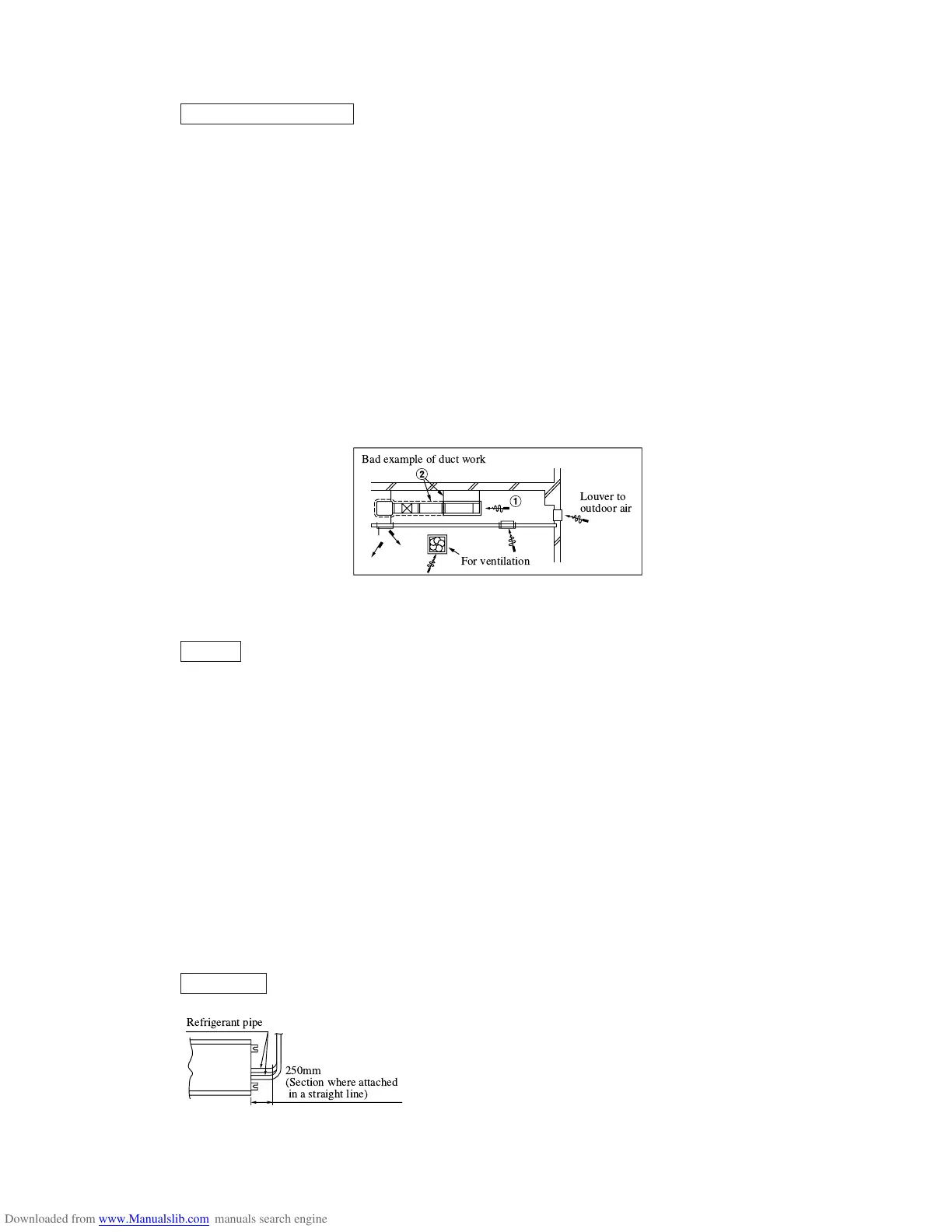

Bad example of duct work

q If a duct is not provided at the suction side but it is substituted with the space over the ceiling, humidity in the space will

increase by the influence of capacity of ventilation fan, strength of wind blowing against the out door air louver, weather

(rainy day) and others.

a) Moisture in air is likely to condense over the external plates of the unit and to drip on the ceiling. Unit should be

operated under the conditions as listed in the above table and within the limitation of wind volume. When the building

is a concrete structure, especially immediately after the construction, humidity tends to rise even if the space over the

ceiling is not substituted in place of a duct. In such occasion, it is necessary to insulate the entire unit with glass wool

(25mm). (Use a wire net or equivalent to hold the glass wool in place.)

b) It may run out the allowable limit of unit operation (Example: When outdoor air temperature is 35˚C DB, suction air

temperature is 27˚C WB) and it could result in such troubles as compressor overload, etc.

c) There is a possibility that the blow air volume may exceed the allowable range of operation due to the capacity of

ventilation fan or strength of wind blowing against external air louver so that drainage from be heat exchanger may fall

to reach the drain pan but leak outside (Example: drip on to the ceiling) with consequential water leakage in the room.

w If vibration damping is not conducted between the unit and the duct, and between the unit and the slab, vibration will be

transmitted to the duct and vibration noise may occur. Also, vibration may be transmitted from the unit to the slab.

Vibration damping must be performed.

(v) Refrigerant pipe

Caution

q Use the new refrigerant pipe.

When re-using the existing pipe system for R22 or R407C, pay attention to the following items.

• Change the flare nuts with the attached ones (JIS category 2), and reprocess the flare parts.

• Do not use thin-walled pipes.

w Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS H3300) for refrigera-

tion pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no harmful sub-

stances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

e Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil. And air getting

into refrigeration circuit may cause over-pressure and resultant it may result in bursting, etc.

r Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any

dust, dirt or water getting into pipe. Otherwise it will cause degradation of refrigeration oil and com-

pressor breakdown, etc.

t Use special tools for R410 refrigerant.

Piping work

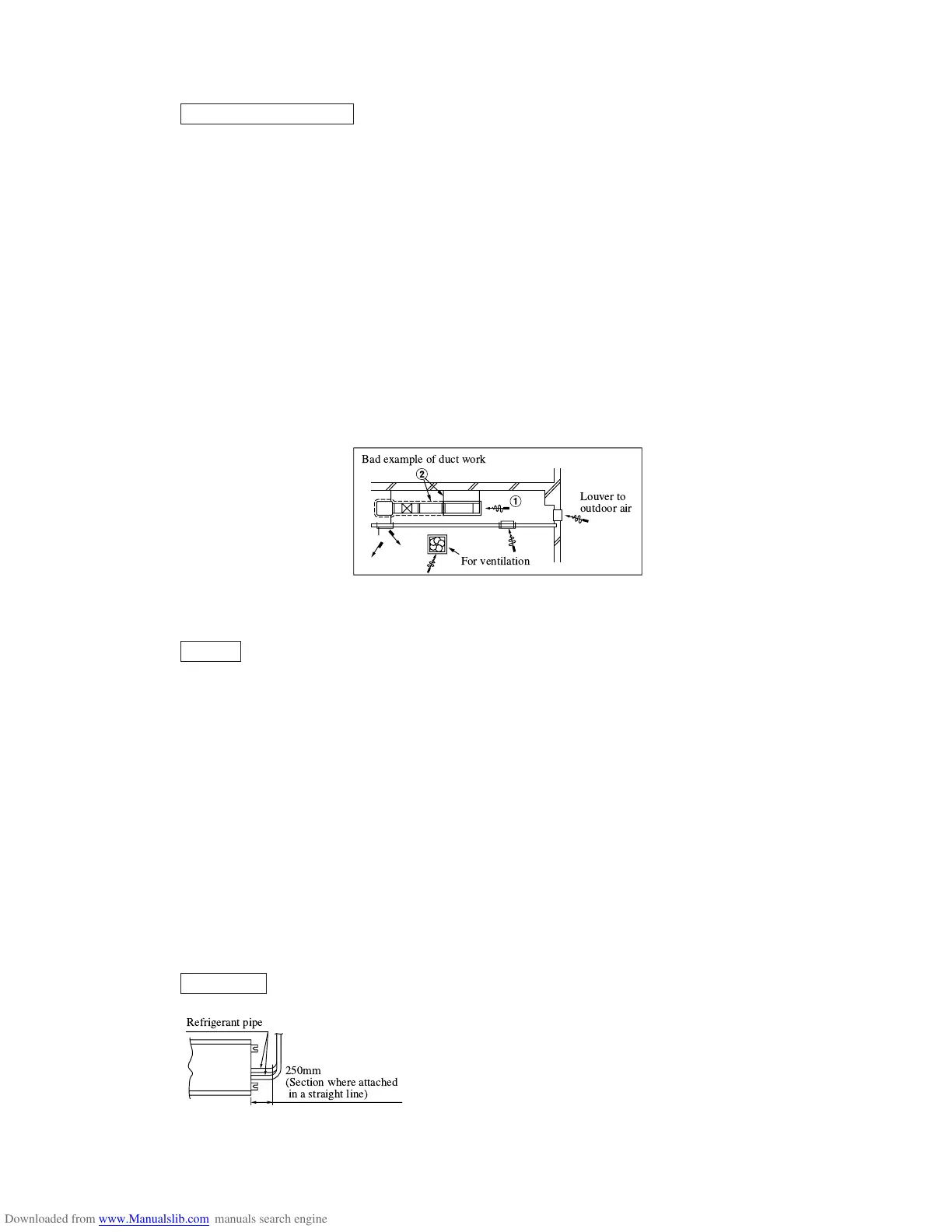

When conducting piping work, make sure to allow the pipes to be aligned

in a straight line for at least 250 mm, as shown in the left illustration. (This

is necessary for the drain pump to function)

Bad example of duct work

Forventilation

Louver to

outdoor air

Loading...

Loading...