-

247

-

(iii) Air tightness test and air purge (Carry them out according to the following steps.)

Air tightness test

q Although an outdoor unit itself has been tested for air tightness at the factory, please check the connected pipes and

indoor units for air tightness from the check joint of the service valve on the outdoor unit side. While conducting a test,

keep the service valve shut all the time.

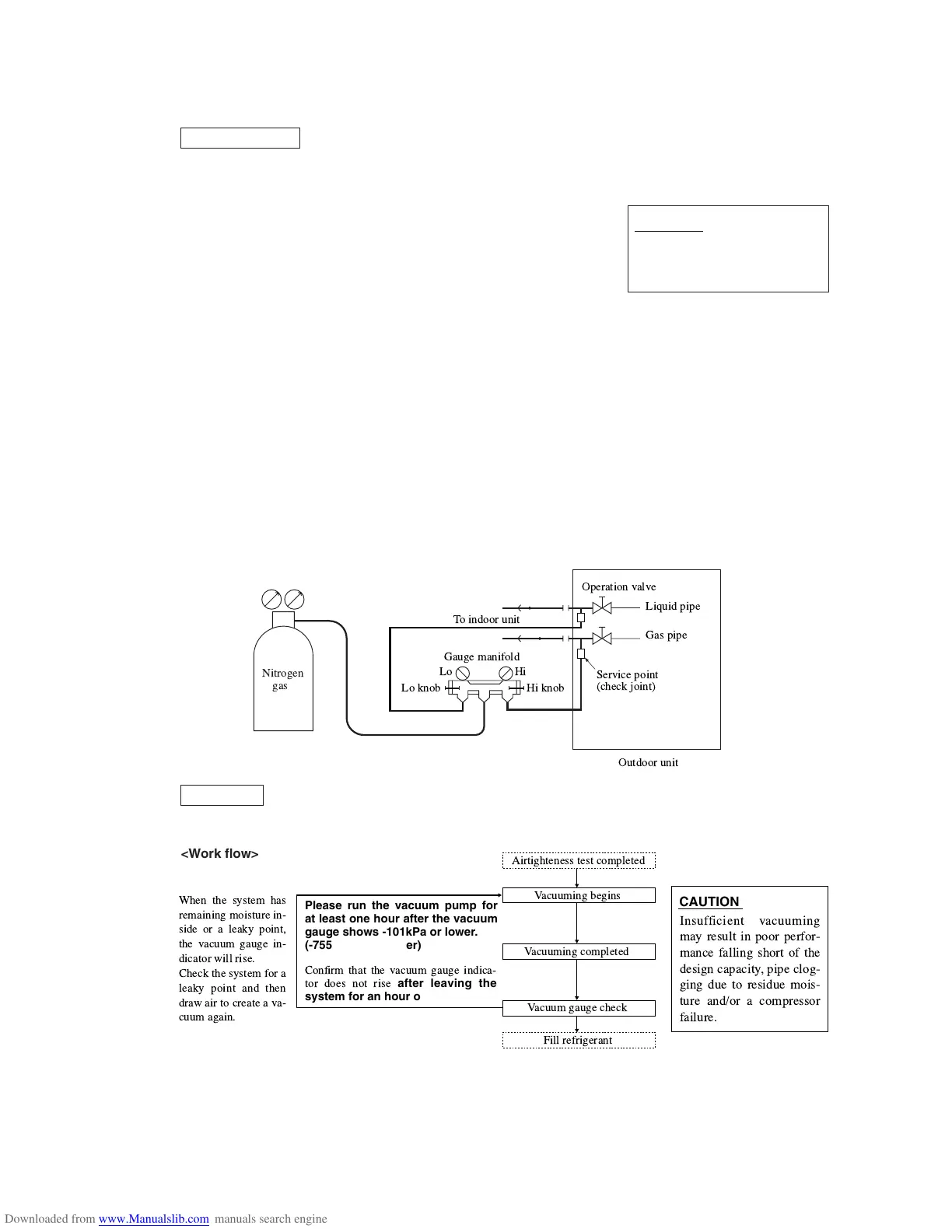

w Since refrigerant piping is pressurized to the design pressure of a unit

with nitrogen gas for testing air tightness, please connect instruments

according the drawing below.

Under no circumstances should chlorine-based refrigerant, oxygen or any

other combustible gas be used to pressurize a system

Keep the service valve shut all the time. Do not open it under any circumstances.

Be sure to pressurize all of the liquid, gas pipes.

e In pressurizing the piping, do not apply the specified level of pressure all at once, but gradually raise pressure.

a) Raise the pressure to 0.5 MPa, and then stop. Leave it for five minutes or more to see if the pressure

drops.

b) Then raise the pressure to 1.5 MPa, and stop. Leave it for five more minutes to see if the pressure drops.

c) Then raise the pressure to the specified level (4.15 MPa), and record the ambient temperature and the pressure.

d) If no pressure drop is observed with an installation pressurized to the specified level and left for

about one day, it is acceptable. When the ambient temperature changes 1°C, the pressure also changes approxi-

mately 0.01 MPa. The pressure, if changed, should be compensated for.

e) If a pressure drop is observed in checking e) and a) - d), a leak exists somewhere. Find a leak by applying bubble test

liquid to welded parts and flare joints and repair it. After repair, conduct an air-tightness test again.

r Always pull air from the pipes after the airtightness test.

Vacuuming

Please pull air from the check joints of the service valves on both liquid and gas sides.

CAUTION

Applying excessive pressure can

cause an inflow of nitrogen gas into

an outdoor unit.

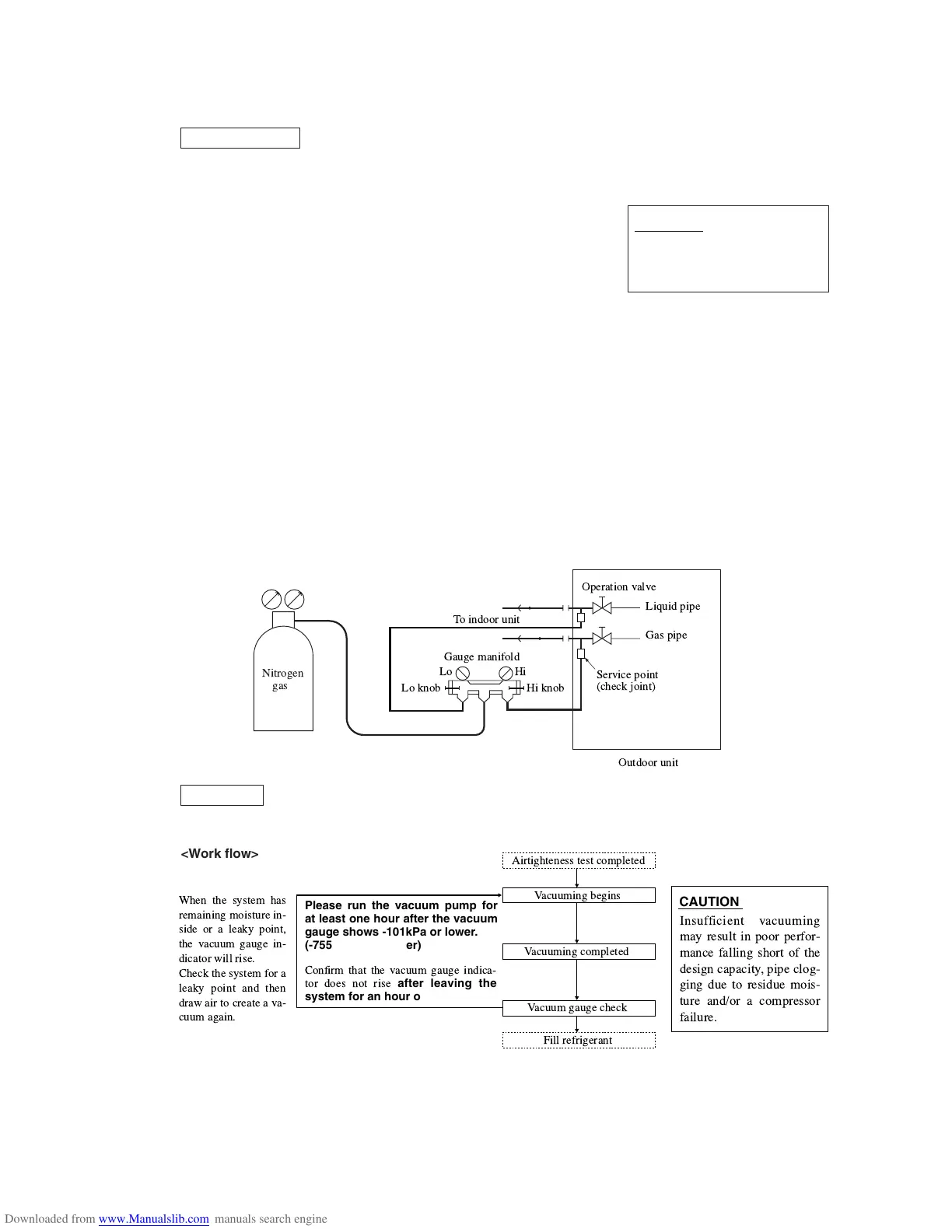

<Work flow>

Fill refrigerant

Airtighteness test completed

CAUTION

Vacuuming begins

Vacuuming completed

Vacuum gauge check

When the system has

remaining moisture in-

side or a leaky point,

the vacuum gauge in-

dicator will rise.

Check the system for a

leaky point and then

draw air to create a va-

cuum again.

Please run the vacuum pump for

at least one hour after the vacuum

gauge shows -101kPa or lower.

(-755mmHg or lower)

Insufficient vacuuming

may result in poor perfor-

mance falling short of the

design capacity, pipe clog-

ging due to residue mois-

ture and/or a compressor

failure.

Confirm that the vacuum gauge indica-

tor does not rise

after leaving the

system for an hour or more.

Loading...

Loading...