-

242

-

!

"#$

"$%

"$%

"#$

"!$#

"!$#

&%

%

"!$#

"'$&#

"!$#

!

"$%

"!$#

"!$#

"'$&#

"$%

"#$

#

%

"$

"!$#

"#$

"!$#

"#$

"$%

"!$#

#$

($

$#

($

$

(!$#

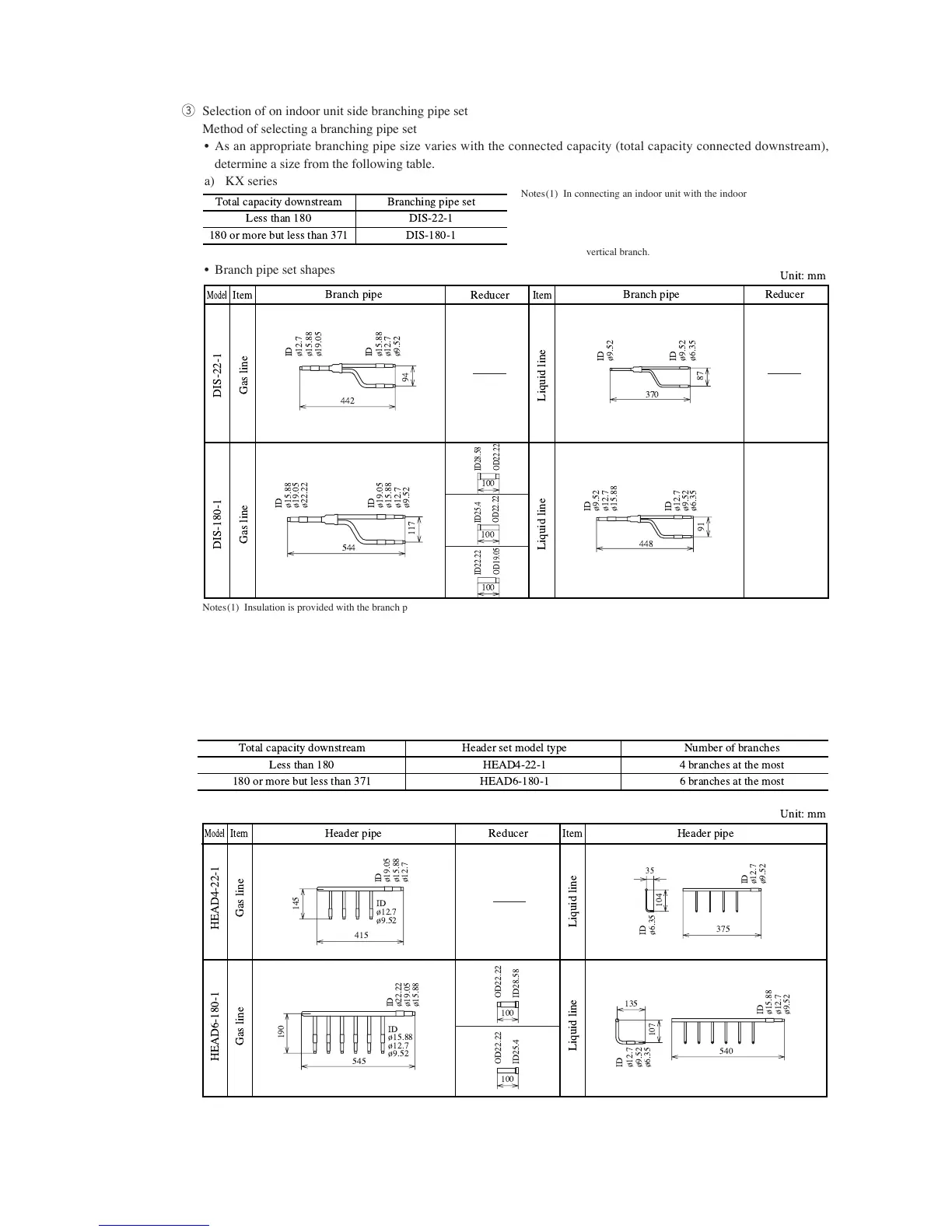

e Selection of on indoor unit side branching pipe set

Method of selecting a branching pipe set

• As an appropriate branching pipe size varies with the connected capacity (total capacity connected downstream),

determine a size from the following table.

a) KX series

Notes(1) In connecting an indoor unit with the indoor unit side branching

pipe set, plase use a pipe conforming to the pipe size specified for

indoor unit connection.

(2) Always install branching joints (for suction gas, discharge gas and

liquid) in such a manner that that they form either correct horizon-

tal or vertical branch.

• Branch pipe set shapes

Notes(1) Insulation is provided with the branch pipes.

(2) Pipes should be cut to the installation site requirements, with the pipe being severed at the center part of the desired diameter.

(3) Branch joints (gas & liquid) must be installed as either a "horizontal branch" or a "vertical branch".

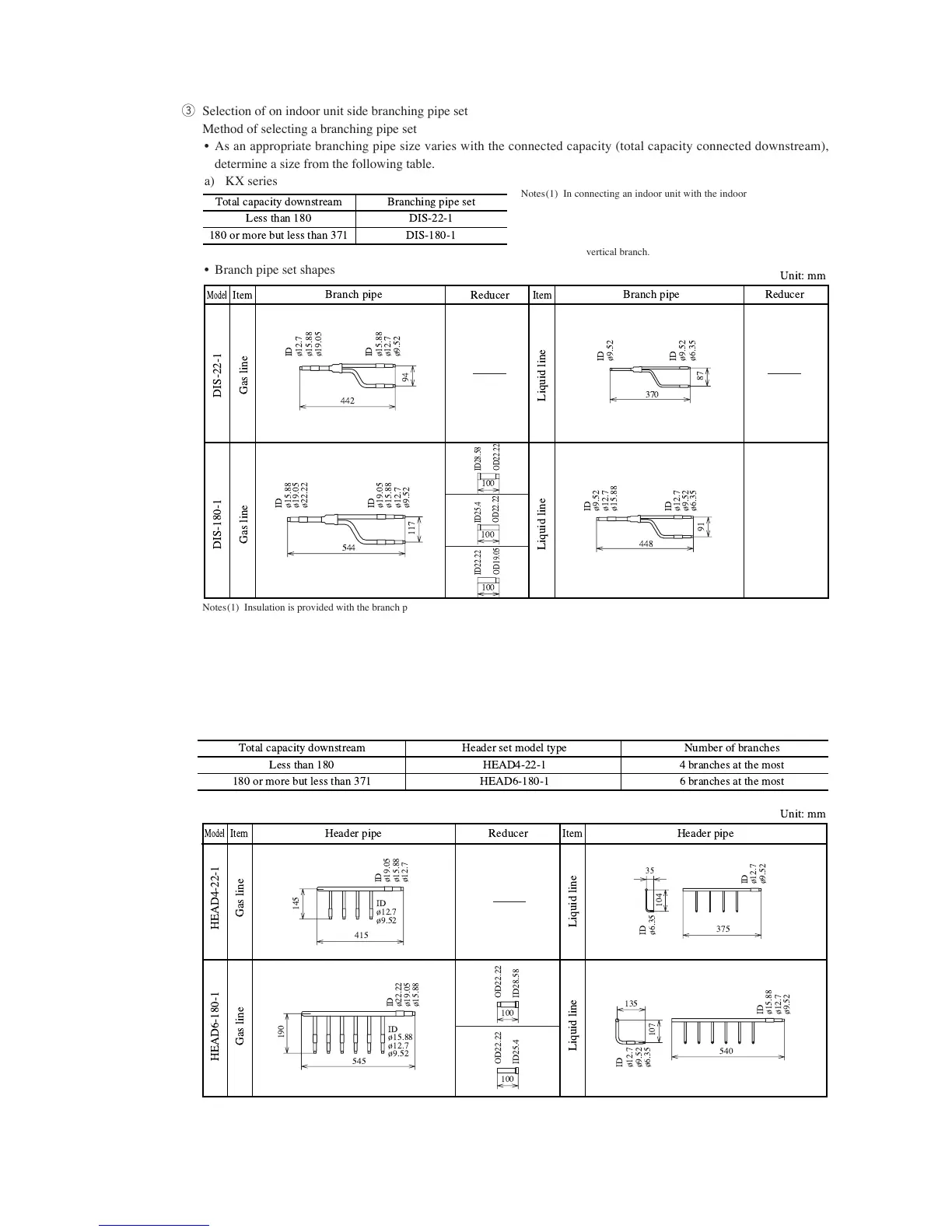

r Header Method

• Depending on the number of units connected, connect plugged pipes (to be procured on the installer’s part) at a

branching point (on the indoor unit connection side).

• For determination of appropriate header, different diameter pipe joint and blind pipe sizes, please refer to “Header

Set,” (which can be purchased separately).

• Header pipe set shapes

Notes(1) Insulation is provided with the branch pipes.

(2) Pipes should be cut to the installation site requirements, with the pipe being severed at the center part of the desired diameter.

(3) Branch joints (gas & liquid) must be installed as either a "horizontal branch" or a "vertical branch".

(4) Indoor units 224 and 280 can not connected to the header.

!

" #

!

!

!

"

"

#$%

#"$

#&$"

!

#&$"

#$%

!

&

""

#$

!

#"$

!

#$%

#&$"

#&$"

#"$

!"$

'$

!$"

'$

("

%

"

#$%

#&$"

#&$"

#$("

#"$

!

#$%

!

("

(%"

#$%

!

#&$"

#$("

!

Loading...

Loading...