-

245

-

a) On-site piping work

Important

● Please take care so that installed pipes may not touch components within a

unit.

● During the pipe installation at site, keep the service valves shut all

the time.

● Give sufficient protections (compressed and brazed or by an adhesive tape)

to pipe ends so that any water or foreign matters may not enter

the pipes.

● In bending a pipe, bend it to the largest possible radius (at least four times the pipe diameter). Do not bend a

pipe repeatedly to correct its form.

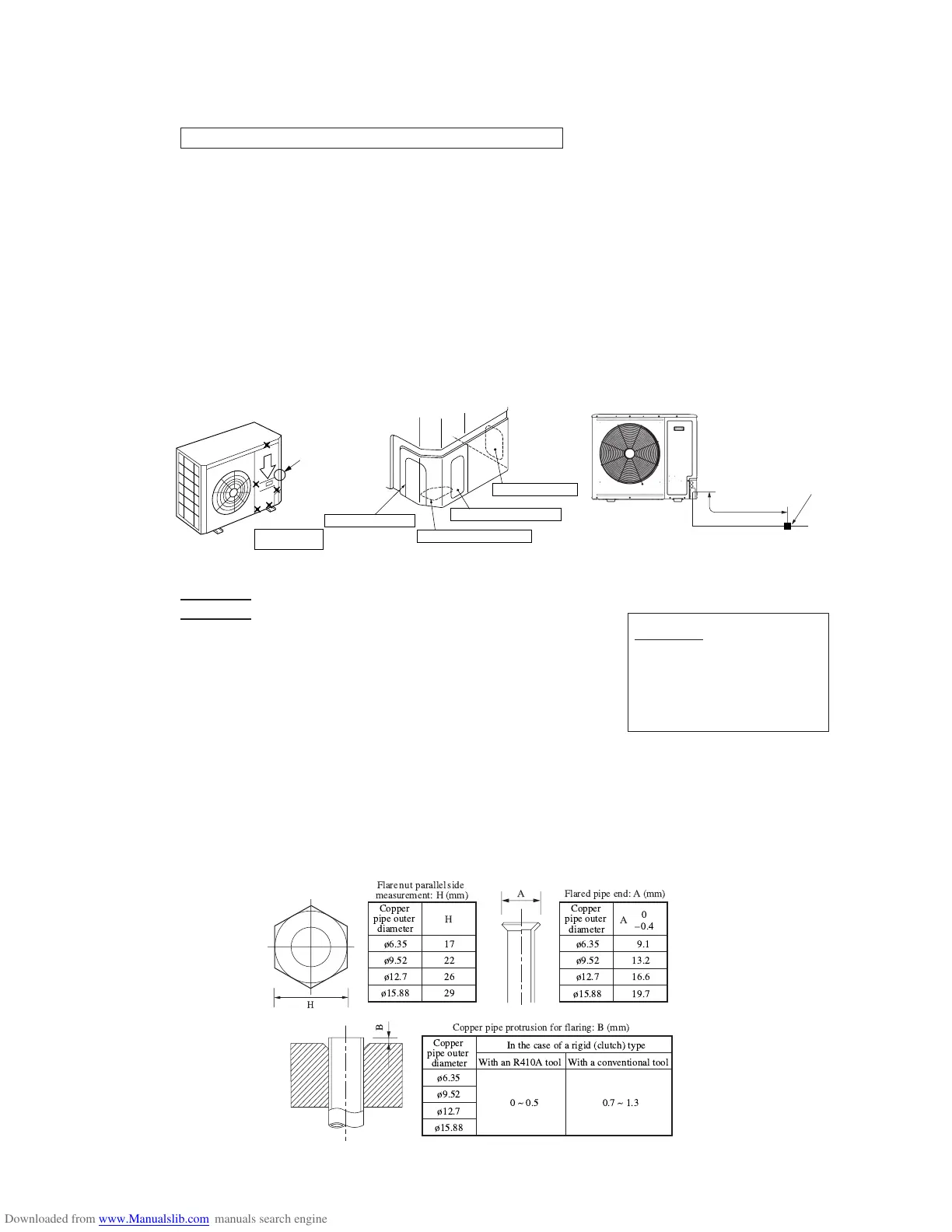

● An outdoor unit’s pipe and refrigerant piping are to be flare connected. Flare a pipe after engaging a flare nut onto it. A

flare size for R410A is different from that for conventional R407C. Although we recommend the use of flaring tools

developed specifically for R410A, conventional flaring tools can also be used by adjusting the measurement of protrusion

B with a protrusion control gauge.

● Tighten a flare joint securely with two spanners. Observe flare nut tightening torque specified in the table below.

(ii) Piping work

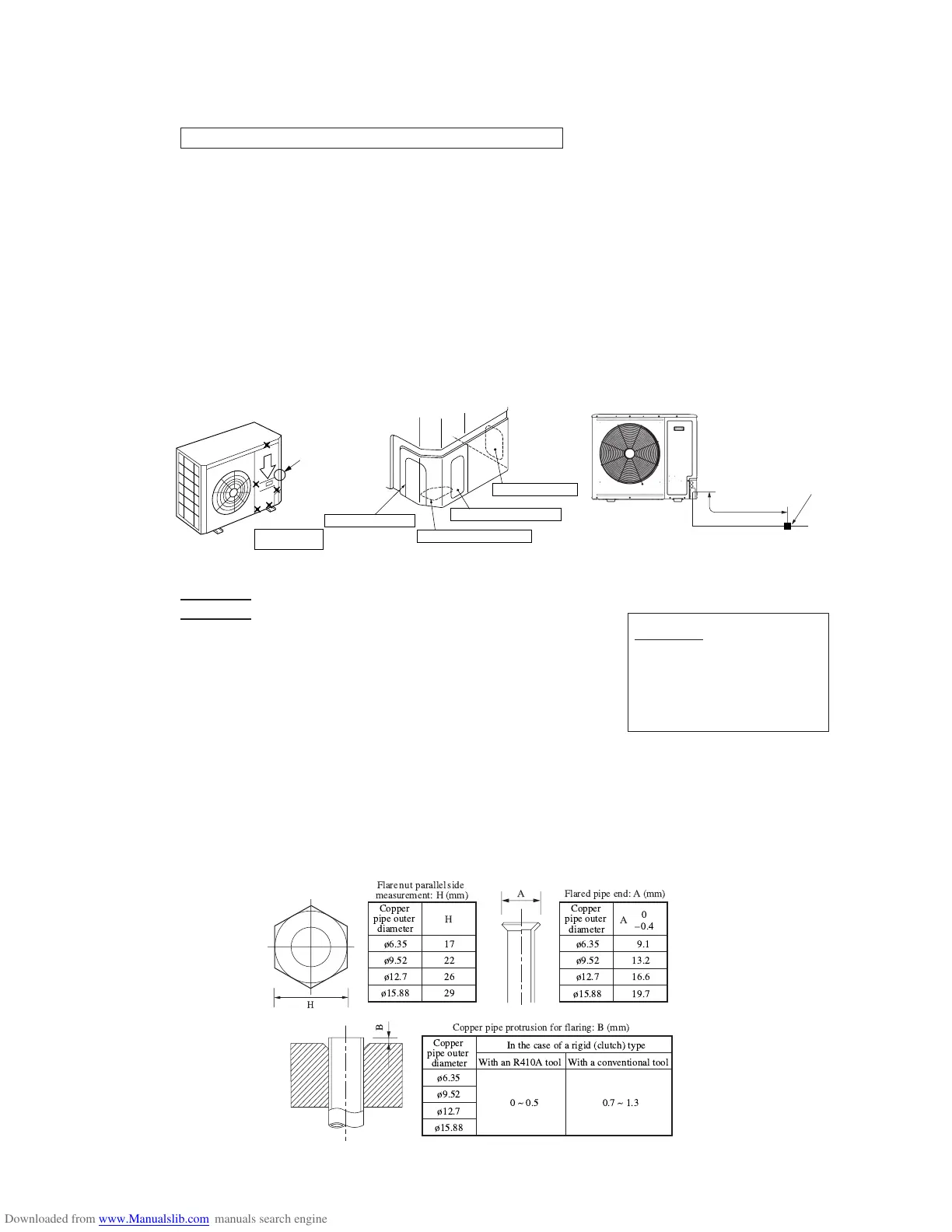

Piping connection position and the piping remove direction

● First remove the five screws ( mark) of the service panel and push it down into the direction of the arrow mark and then

remove it by pulling it toward you.

● The pipe can be laid in any of the following directions: side right, front, rear and downward.

● Remove a knock-out plate provided on the pipe penetration to open a minimum necessary area and attach an edging

material supplied as an accessory by cutting it to an appropriate length before laying a pipe.

● In laying pipes on the installation site, cut off the casing’s half blank that covers a hole for pipe penetration with nippers.

● If there is a risk of small animals entering from the pipe penetration part, close the part with some sealing material or the

like (to be arranged on the installer’s part).

● In the case of an installation using a collective drain system, use a port other than the bottom one to take out cables and

pipes. If the bottom port is used, seal it thoroughly so that drain water may not spill out.

● Use an elbow (to be arranged on the user’s part) to connect control valves to the piping.

● In anchoring piping on the installation site, give 1.5m or a longer distance between an outdoor unit and an anchoring point

where the piping is secured as illustrated below. (A failure to observe this instruction may result in a pipe fracture depending

on a method of isolating vibrations employed.)

Over 1.5m

For front connection

For downward connection

For side right connection

For rear connection

Catch

Outdoor unit

Pipe fastening position

CAUTION

If you tighten it without using

double spanners, you may deform

the service valve, which can cause

an inflow of nitrogen gas into the

outdoor unit.

!

"

#

"$

% & ' ''& (

)& *$" )& '+

"," " ,

!

Loading...

Loading...