4

Creating a ShopTurn Program 08/2005

4.2 Bases

4

♥ Siemens AG, 2005. All rights reserved

4-128 SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition

4.2.2 Approaching/retracting in the machining cycle

Approaching and retracting during the machining cycle always follows

the same pattern if you have not defined a special approach/retraction

cycle (see Sec. "Programming the approach/retraction cycle"). If the

machine has a tailstock, you can also take it into consideration when

traversing.

The retraction for a cycle ends at the safety distance. Only the

subsequent cycle moves to the retraction plane. This allows the use of

the special approach/retraction cycle (see Sec. "Programming the

approach/retraction cycle").

During the choosing of the traversing path, ShopTurn always

considers the tool tip, i.e. the elongation of the tool is not taken into

consideration. Be careful therefore that the retraction planes are

correspondingly far away from the workpiece.

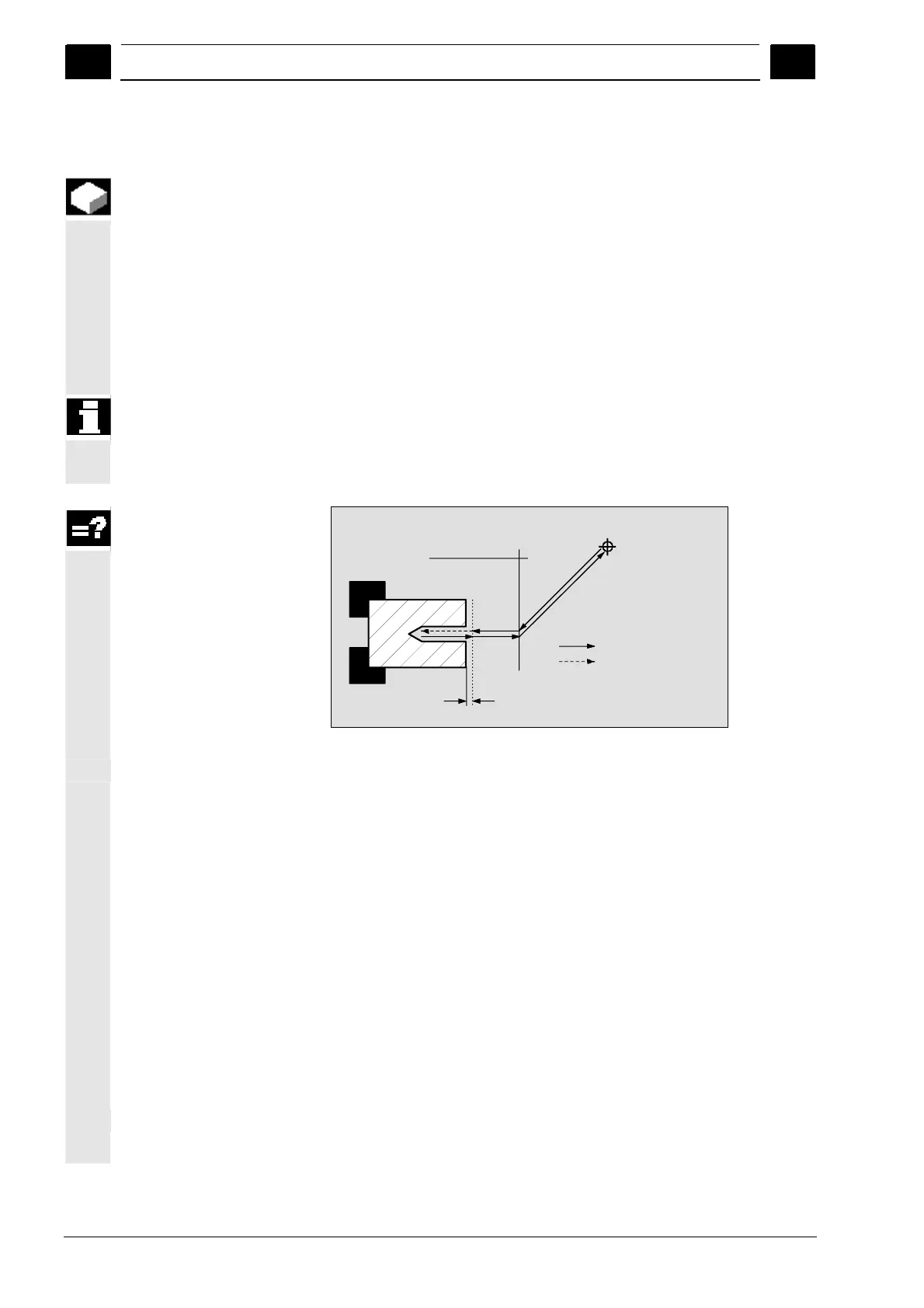

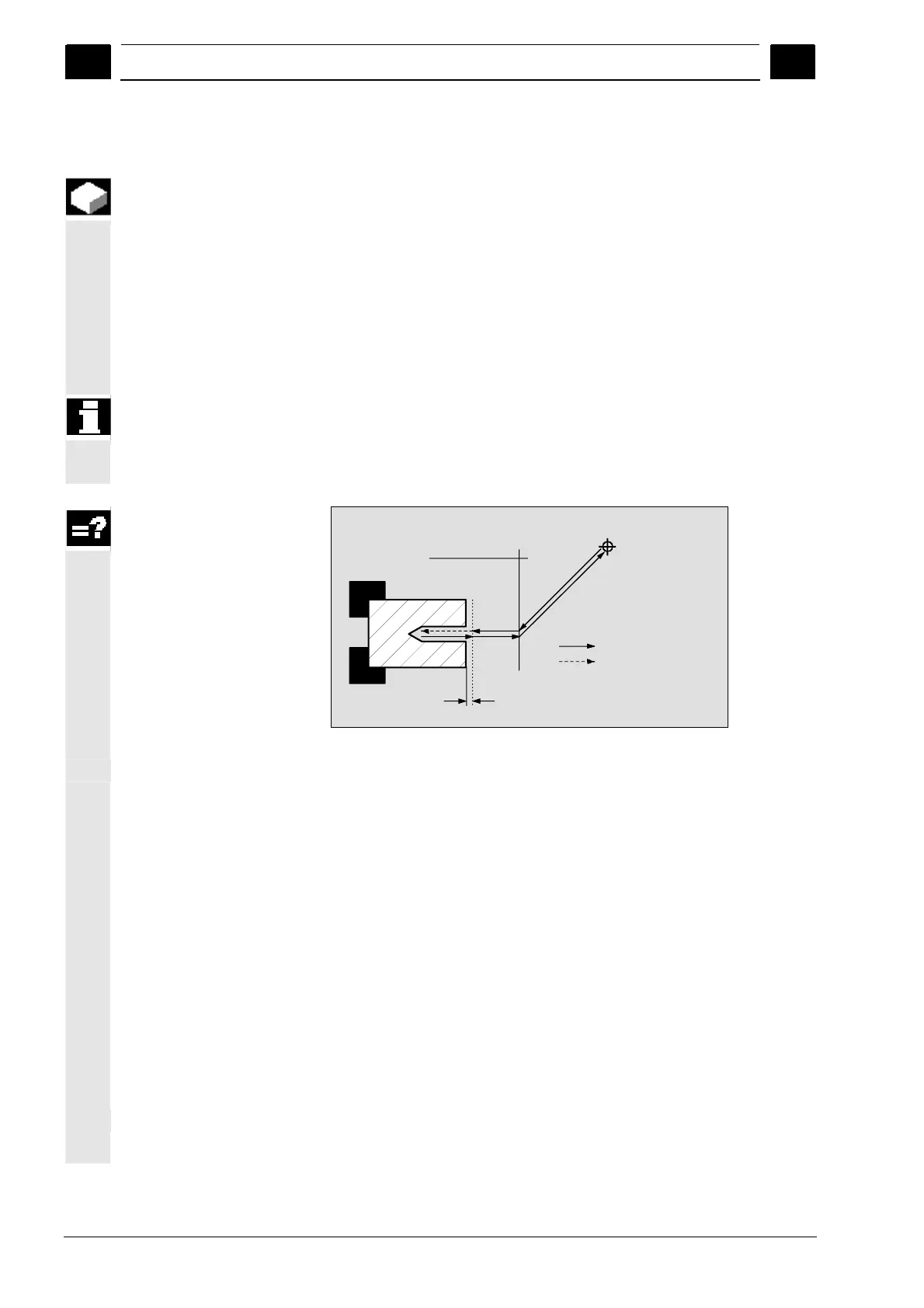

Safety distance

Retract plane

Tool change point

Rapid traverse

Machining feedrate

Approach/retraction of machining cycle

The tool travels in rapid traverse along the shortest path from the

tool change point to the retraction plane which runs parallel to the

machining plane.

After this, the tool travels in rapid traverse to the safety distance.

Then the machining of the workpiece takes place with the

programmed machining feedrate.

After the machining, the tool retracts vertically in rapid traverse to

the safety distance.

Then the tool continues to travel vertically in rapid traverse to the

retraction plane.

From there, the tool travels in rapid traverse along the shortest

path to the tool change point.

If the tool does not need to be changed between two machining

processes, the tool travels from the retraction plane to the next

machining cycle.

The spindle (main, tool, or counter-spindle) begins to rotate

immediately after the tool change.

Loading...

Loading...