5

08/2005 ShopTurn Functions

5.2 Drillin

5

♥ Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition 5-167

5.2 Drilling

The functions explained in this section are used when you want to

program various drill holes on the end face or peripheral surface.

You program drilling operations in the order in which they are

performed. The following technology cycles can be used:

Drill centered

Thread centered

Centering

Drilling

Reaming

Deep-hole drilling

Thread tapping

Thread milling

You have to program the positions or position pattern after the

technology cycles.

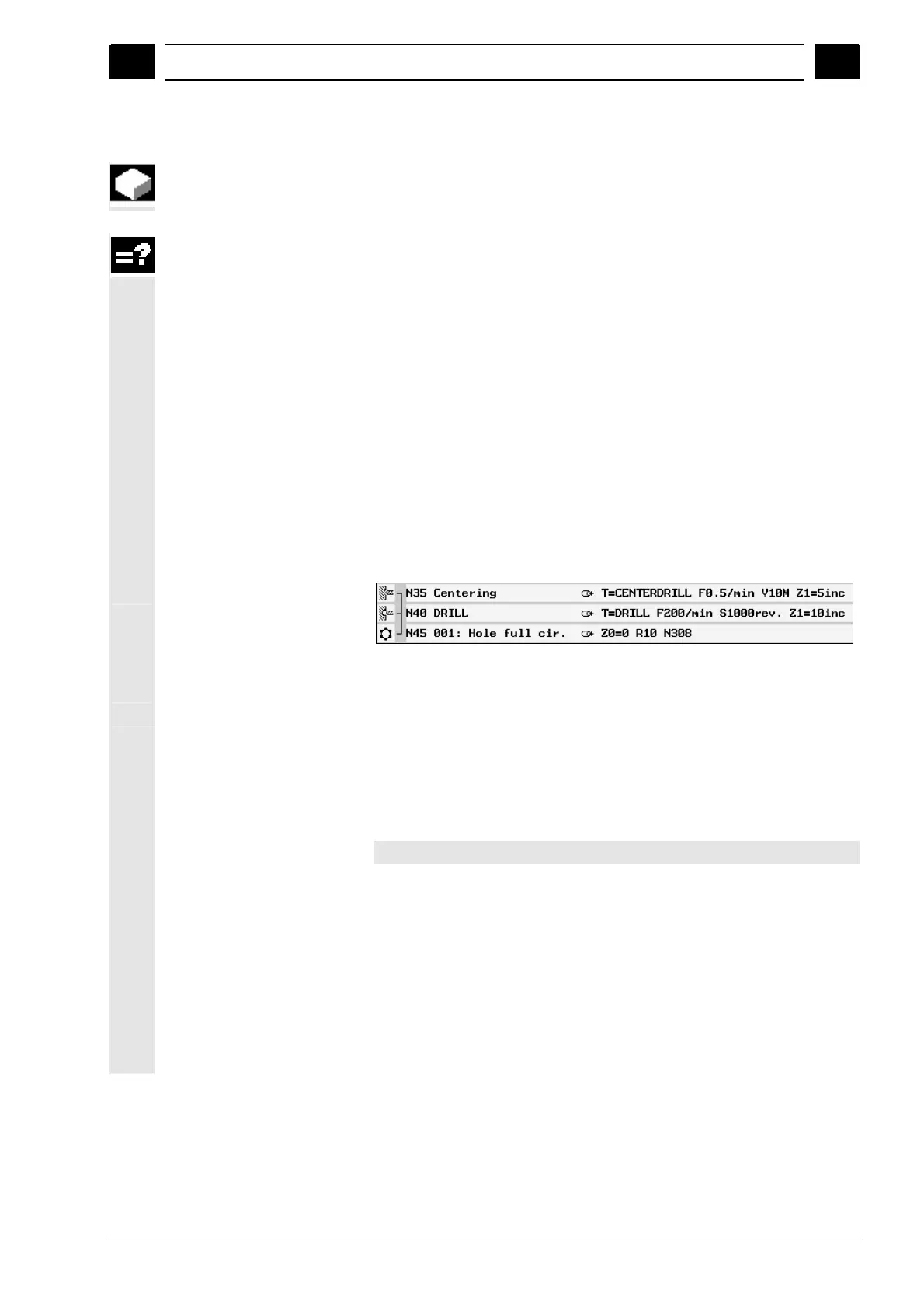

All program blocks involved in the drilling operation are shown in the

process plan in square brackets.

Example: Drilling

Clamp spindle

With off-center drilling, it can be helpful to clamp the spindle to avoid

spindle distortions. The "Clamp spindle" function must be set up by

the machine manufacturer. The machine manufacturer also specifies

whether ShopTurn will clamp the spindle automatically if this would

facilitate machining, or if you can decide the types of machining for

which the spindle should be clamped.

Please also refer to the machine manufacturer's instructions.

If you are to decide the types of machining for which the spindle is to

be clamped, the following applies:

You should note that when machining in planes End face/End face C

and Peripheral surface/Peripheral surface C, clamping remains

activated only until the drilling operation ends. When machining in

planes End face Y and Peripheral surface Y, on the other hand,

clamping is modal, i.e. it remains activated until the machining plane is

changed or clamping is deselected in the "Straight circle" Æ "Tool"

menu.

Loading...

Loading...