2

Setting Up the Machine 08/2005

2.5 Tools

2

♥ Siemens AG, 2005. All rights reserved

2-54 SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition

2.5 Tools

The various tool geometry parameters must be referenced while the

program is running. These are entered in the tool list as so-called tool

offset data. For each call-up of a tool, the controller takes the tool

offset data into consideration.

When programming therefore, you only have to enter the workpiece

dimensions from the finishing drawing. After this, the controller

independently calculates the individual tool path.

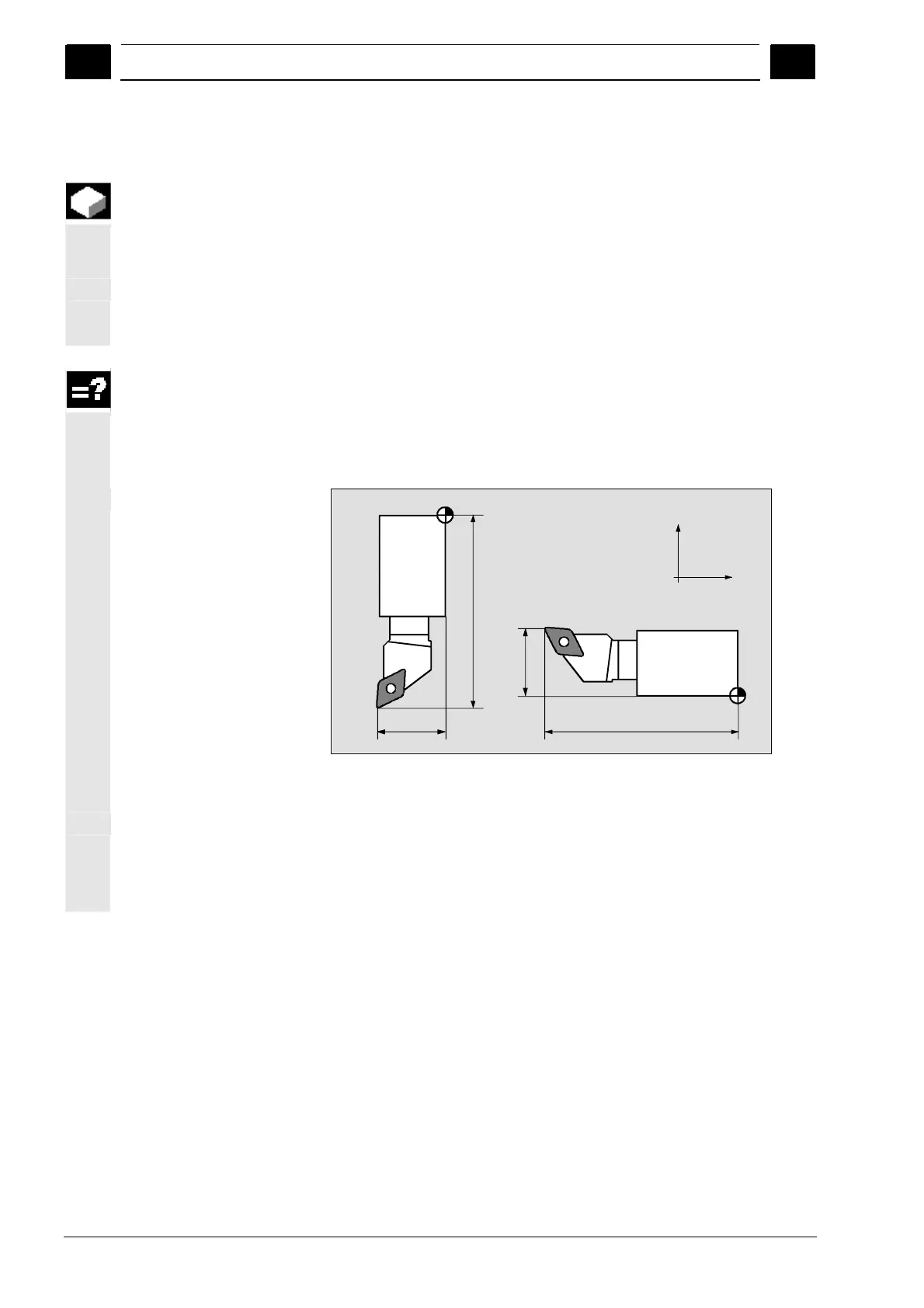

Tool length offset

The tool length offset compensates for the length differences between

the various tools in the X and Z direction.

The tool length is the distance between the tool-carrier reference point

T and tool tip P. If the tool is tensioned in the revolver for a new

machining direction, other tool length offsets will result.

T

T

Length Z

Length Z

Length X

Length X

P

P

X

Z

Tool length offsets

You can determine the tool length offset using the "Measure tool"

function or manually with calipers or a magnifying glass.

The control calculates the traversing movements from the tool length

offset and wear values (see Sec. "Entering Tool Wear Data").

Loading...

Loading...