5

08/2005 ShopTurn Functions

5.14 Insertin

G code into the se

uential control

ro

ram

5

♥ Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition 5-327

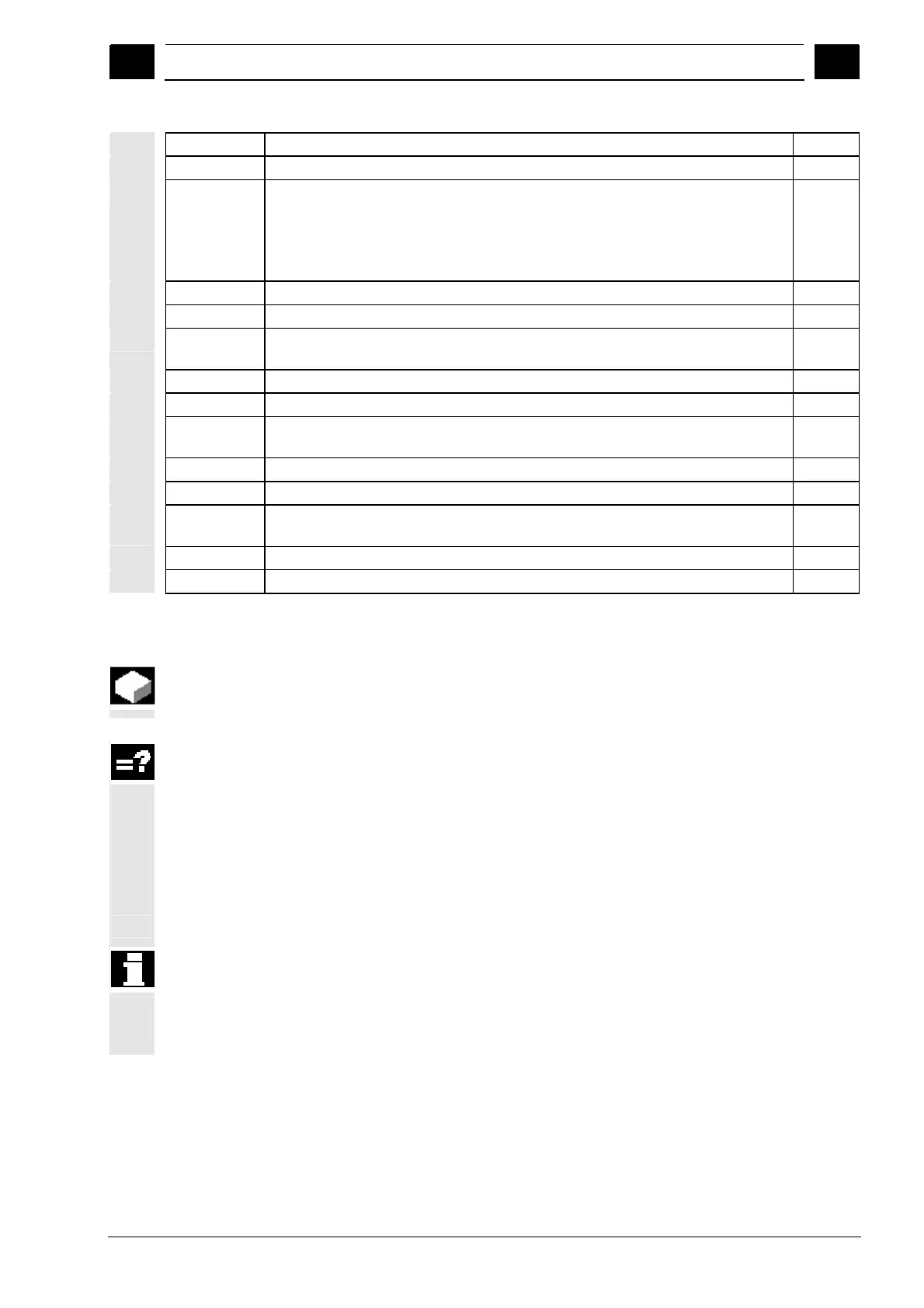

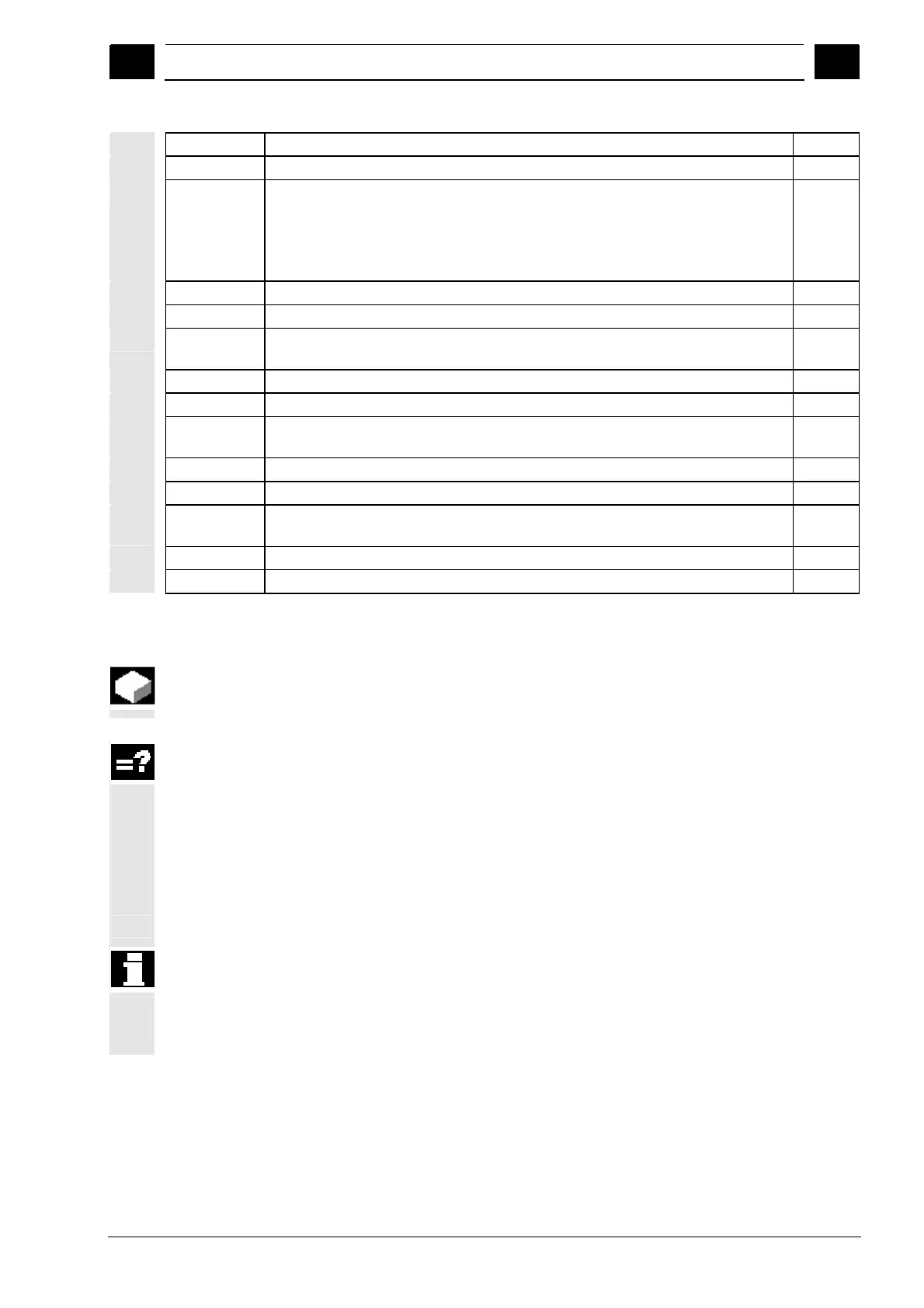

X3

3. Position (inc) or 3rd position ¬ (abs)

mm

Z3 3. position (abs or inc) mm

Tool change TlChngPt: Approach tool change point from the last position programmed

and change tool

Direct: Do not change tool at tool change point, but at the last

position programmed

No: Do not change tool

T Tool name (not with tool change "no")

D Edge number (not with tool change "no")

F4 Feedrate for approach to fourth position

Alternative to rapid traverse

mm/min

X4

4. Position (inc) or 4th position ¬ (abs)

mm

Z4 4. position (abs or inc) mm

F5 Feedrate for approach to fifth position

Alternative to rapid traverse

mm/min

X5

5. Position (inc) or 5th position ¬ (abs)

mm

Z5 5. position (abs or inc) mm

F6 Feedrate for approach to sixth position

Alternative to rapid traverse

mm/min

X6

6. Position (inc) or 6

th

position ¬ (abs)

mm

Z6 6. position (abs or inc) mm

5.14 Inserting G code into the sequential control program

You can program G code blocks in a sequential control program. You

can also insert comments to explain the program.

You will find a detailed description of G code blocks to DIN 66025 in:

References: /PG/, Programming Guide Fundamentals

SINUMERIK 840D/840Di/810D

/PGA/, Programming Guide Advanced

SINUMERIK 840D/840Di/810D

You cannot insert G code blocks before the program header, after the

end of the program or within a chained sequence of program blocks.

ShopTurn does not display G code blocks in the program graphics.

If you want to stop machining of the workpiece at specific points, you

should program the G code command "M01" at these points in the

process plan (see Section "Controlling the program run").

Loading...

Loading...