MAINTENANCE MAINTENANCE PROCEDURE

4-29

CHECK AND ADJUST TRACK TENSION 4

WARNING

For details of starting the engine and operating the work equipment, see “BEFORE STARTING ENGINE (3-

56)“, “STARTING ENGINE (3-72)“, “AFTER STARTING ENGINE (3-76)“, and “WORK EQUIPMENT CON-

TROLS AND OPERATIONS (3-91)“ in the OPERATION section.

Wear on pins and bushings of the undercarriage will vary with working conditions and a type of soil, so inspect the

track tension every now and then in order to maintain the standard tension.

For carrying out inspection and adjustment of track shoes, park the machine on the flat and solid ground.

Checking

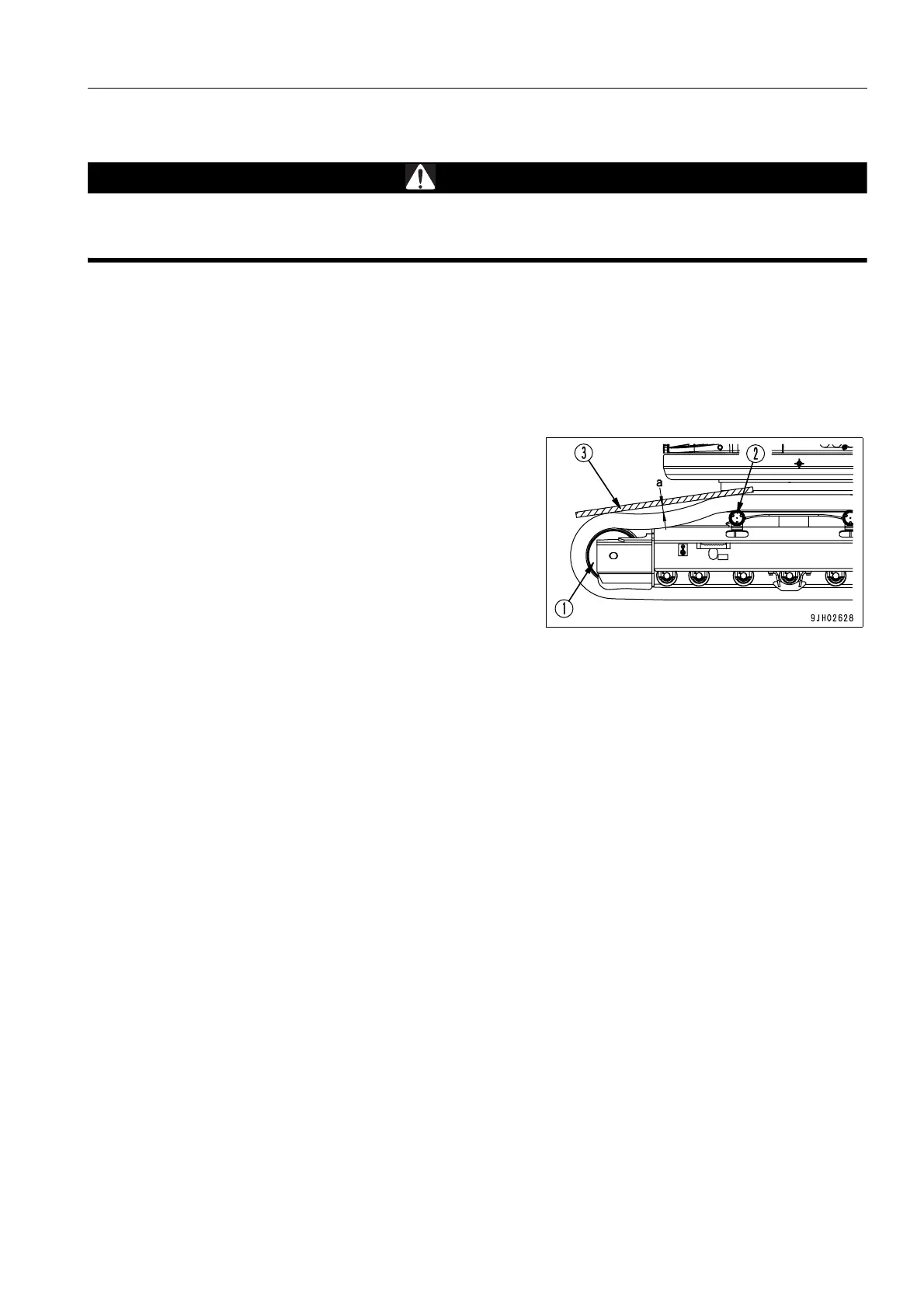

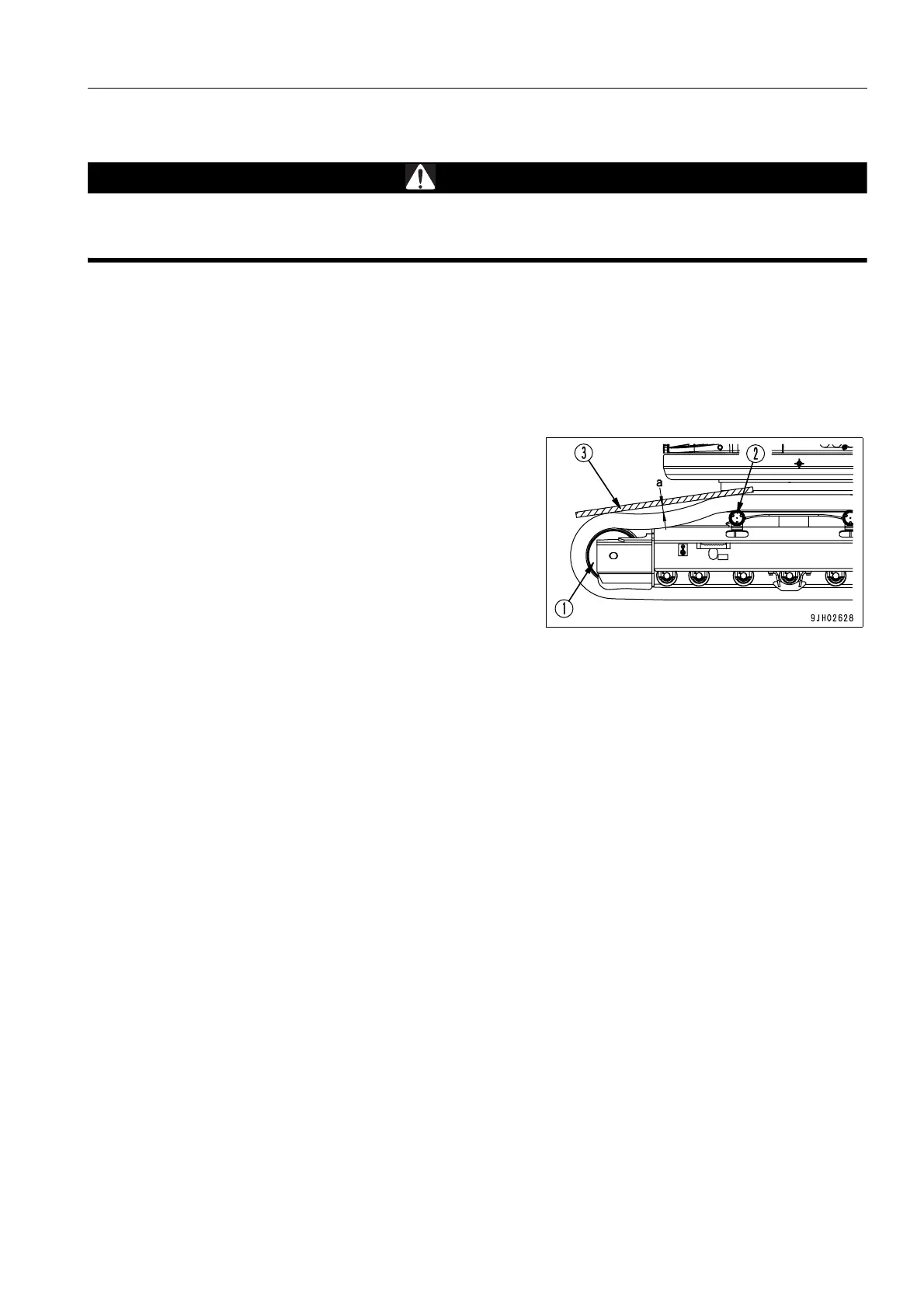

1. Run the engine at low idling, then travel the machine for-

ward for a distance equal to the track length on ground and

stop the machine slowly.

2. Put on the track shoe straight wooden bar (3) which

stretches from idler (1) to upper carrier roller (2).

3. Measure the maximum deflection between the bottom sur-

face of the wooden bar and the top surface of the track

shoe.

Deflection “a“ should be 10 to 30 mm.

Loading...

Loading...