MAINTENANCE PROCEDURE MAINTENANCE

4-32

REPLACE BUCKET TEETH (VERTICAL PIN TYPE) 4

Replace the bucket teeth before the adapter starts to wear.

WARNING

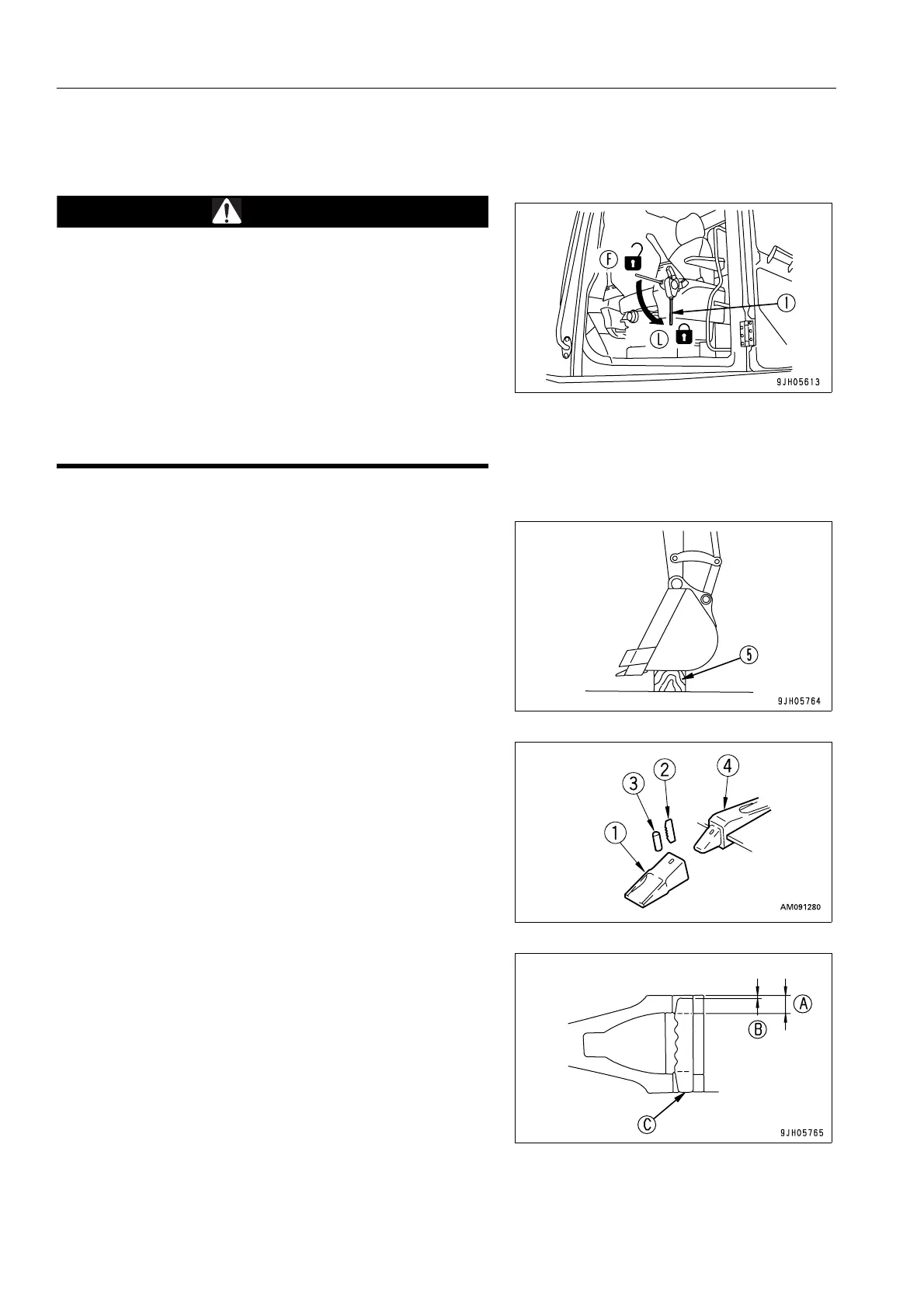

q It is dangerous if the work equipment is mistakenly

moved when replacing the teeth.

Set the work equipment in a stable condition, stop the

engine, then set safety lock lever (1) securely to the

LOCK position (L).

q As the locking pin is knocked out with force, there is

danger that the pin may fly out. Check that there is no

one near the machine.

q Broken pieces may fly during the replacement opera-

tion, so always wear safety glasses, gloves, or other

protective equipment.

1. To make it possible to knock out the pin of tooth (1), put

block (5) under the bottom of the bucket, and set so that

the bottom surface of the bucket is horizontal.

2. Use a hammer and drift to knock out lock pin (2). (If the drift

is set against rubber pin lock (3) when it is hit, the rubber

pin lock may break. Set it against the back of the pin.)

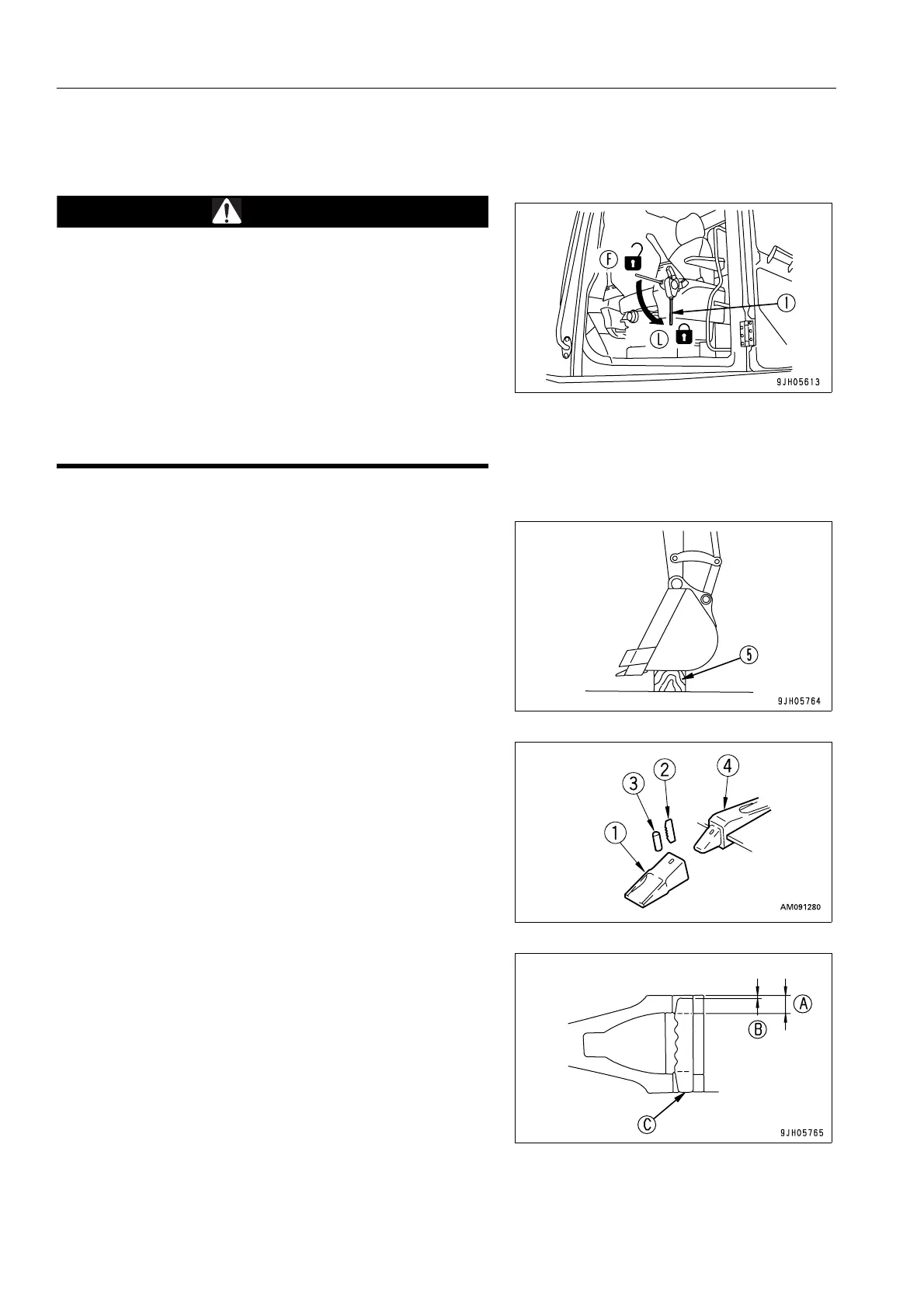

3. After removing lock pin (2) and rubber pin lock (3), check

them.

If lock pin (2) and rubber pin lock (3) are used in the condi-

tion below, it will cause tooth (1) to come off during opera-

tion. Always replace them with new parts.

q Lock pin (2) is too short.

Dimension (B) is less than 1/3 A when lock pin (2) is

aligned at bottom surface (C).

Loading...

Loading...