MAINTENANCE MAINTENANCE PROCEDURE

4-61

REPLACE HYDRAULIC OIL FILTER ELEMENT 4

WARNING

When the oil filler cap is removed, oil may spurt out, so turn the cap slowly to release the pressure before

removing the cap.

NOTICE

If the machine is equipped with a hydraulic breaker, the hydraulic oil will deteriorate much faster than dur-

ing normal bucket operations. For details, see “MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

(4-18)“ when carrying out maintenance.

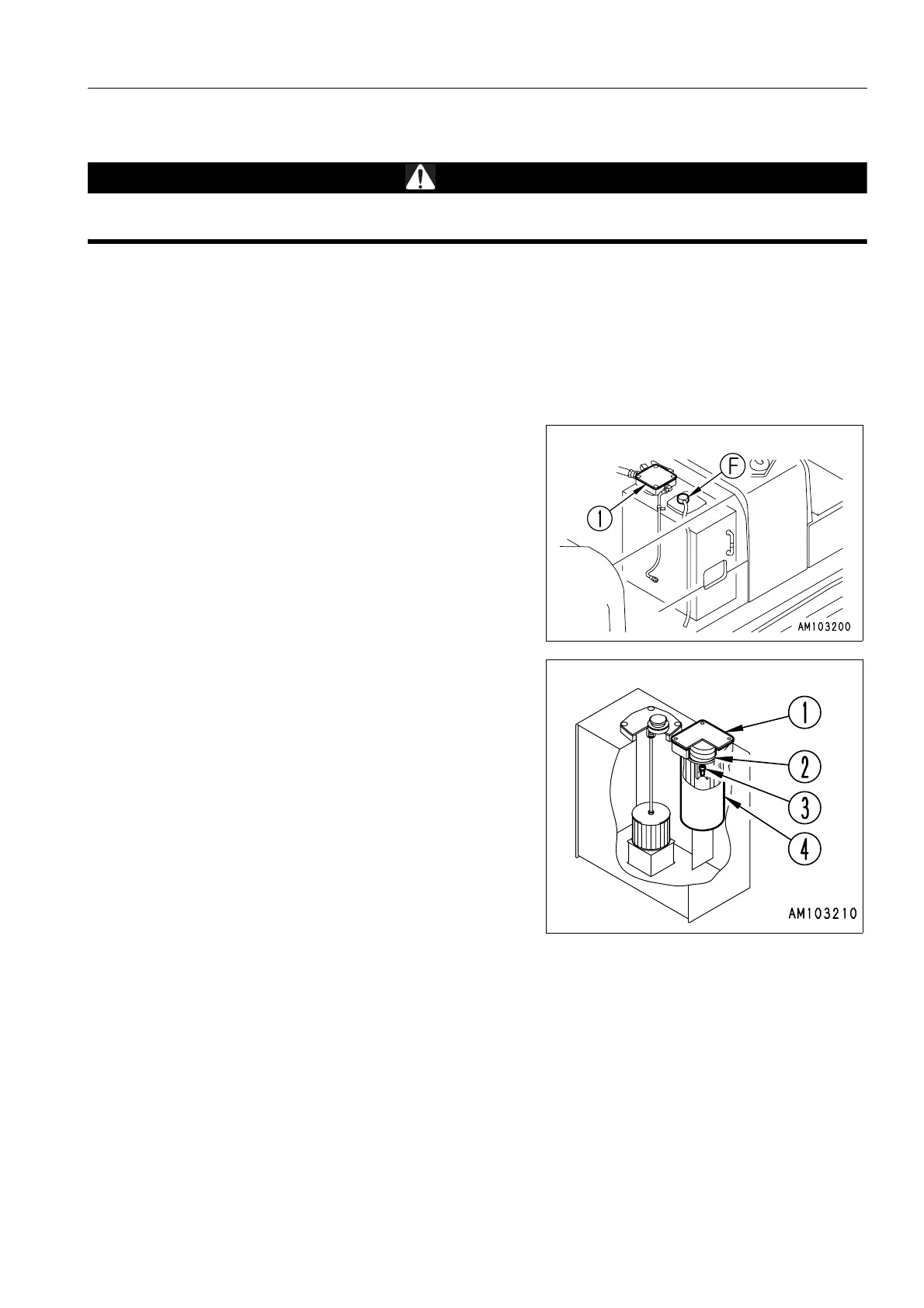

1. Remove the cover at the top of the hydraulic tank.

2. Remove the cap from oil filler (F), and release the internal

pressure.

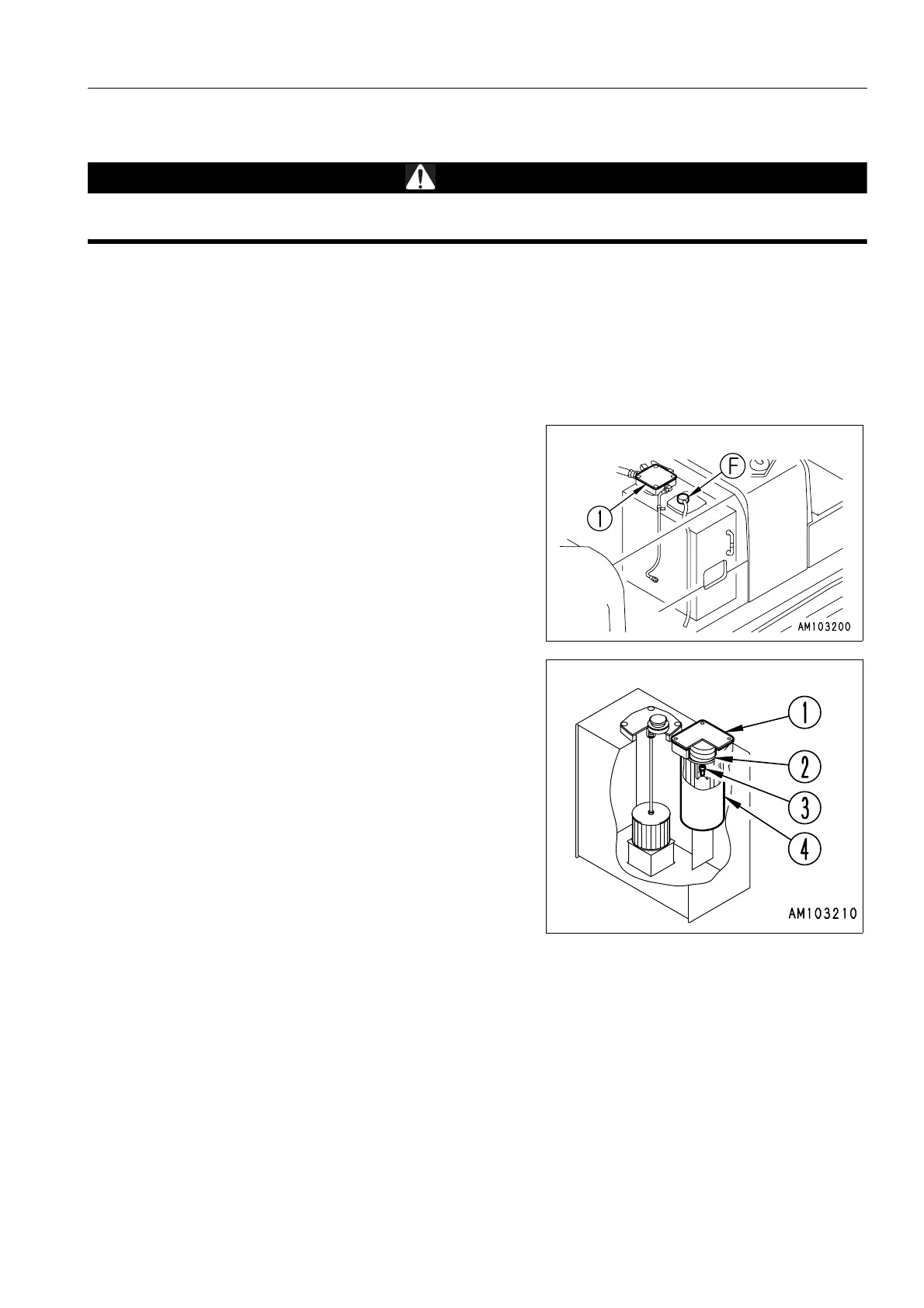

3. Loosen 4 bolts, then remove cover (1).

When doing this, the cover may fly out under the force of

spring (2), so hold the cover down when removing the

bolts.

4. After removing spring (2) and valve (3), take out element

(4).

5. Clean the removed parts in diesel oil.

6. Install the new element in the place where old element (4)

was installed.

7. Set valve (3) and spring (2) on top of the element.

8. Set cover (1) in position, push it down by hand, and install

the cover with the mouning bolts.

9. Install the oil filler cap, then install the cover at the top of

the hydraulic tank.

10. To bleed the air, start the engine according to “STARTING

ENGINE (3-72)“ and run the engine at low idling for 10 min-

utes.

11. Stop the engine.

REMARK

Wait for at least 5 minutes after stopping the eigine to eliminate bubbles in the oil inside the tank.

12. Check for oil leakage and wipe off any spilled oil.

Loading...

Loading...