MAINTENANCE PROCEDURE MAINTENANCE

4-36

ADJUST BUCKET CLEARANCE 4

WARNING

It is dangerous if the work equipment is mistakenly moved

when adjusting the bucket clearance.

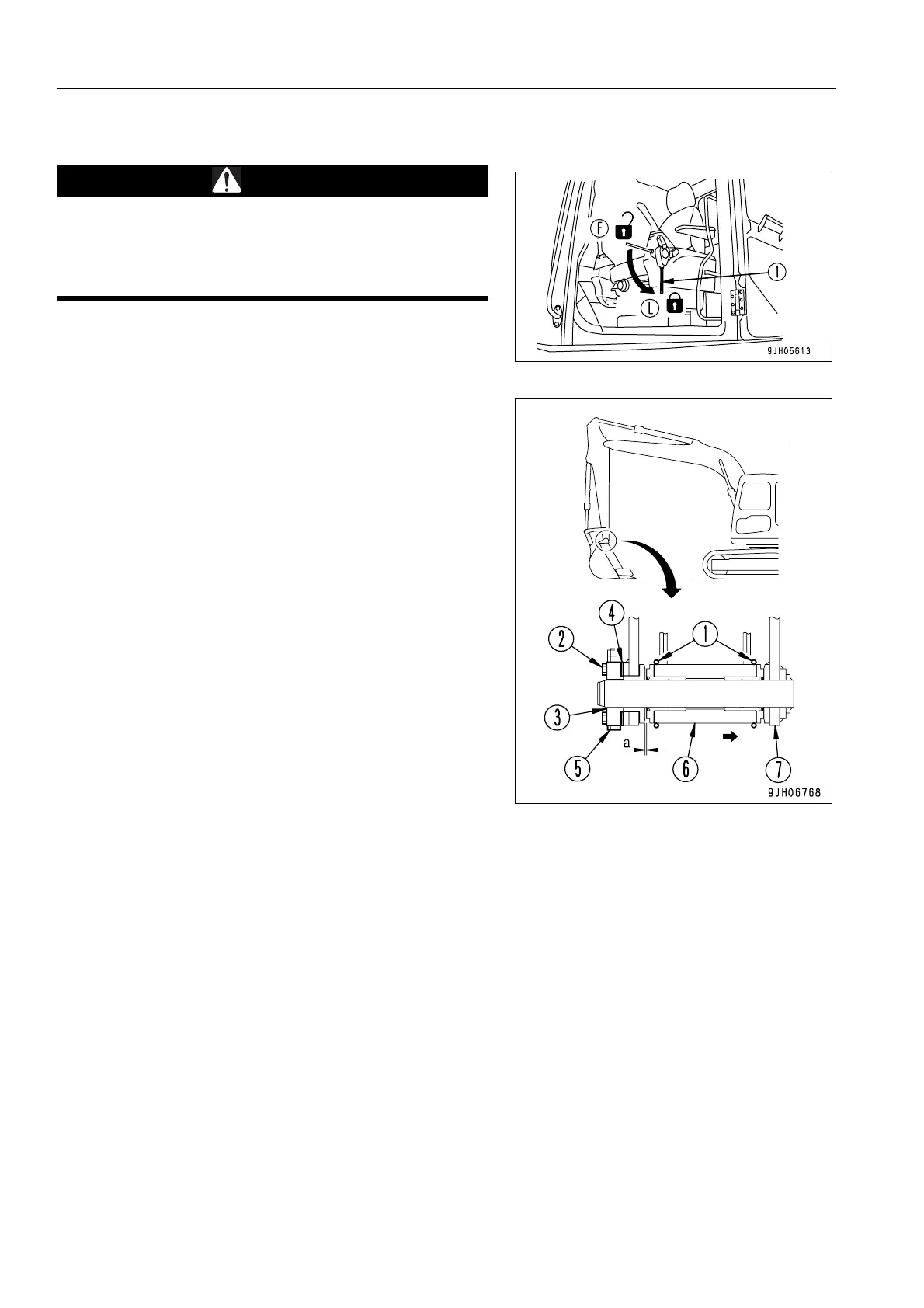

Set the work equipment in a stable condition, stop the

engine, then set safety lock lever (1) securely to the LOCK

position (L).

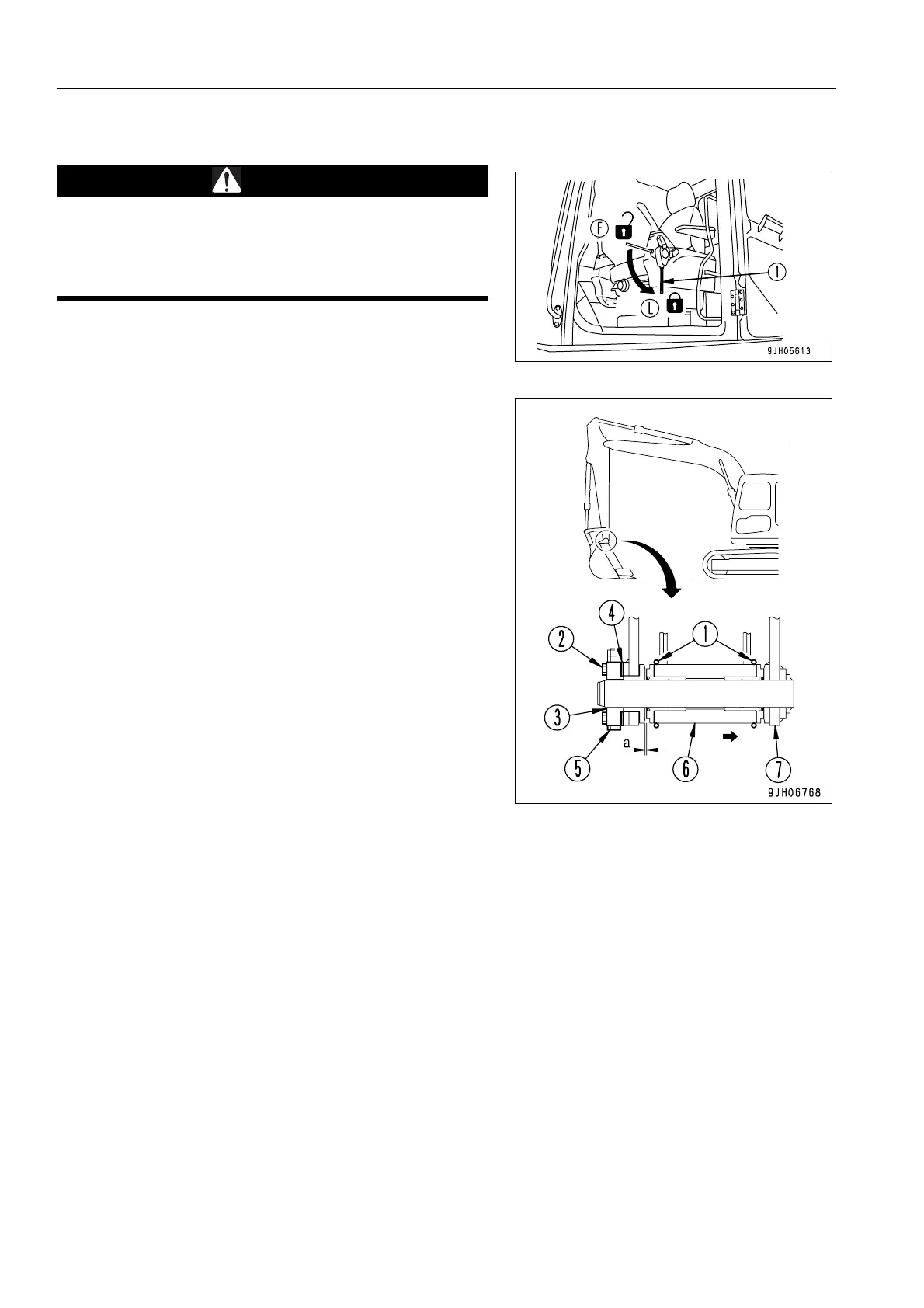

1. Set the work equipment to the position shown in the dia-

gram on the right, then stop the engine and set the lock

lever to the LOCK position.

2. Shift O-ring (1) of the linkage and measure the amount of

play “a“.

Measurement is easier of you move the bucket to one side

or the other so all the play can be measured in one place.

(In the diagram this is on the left-hand side)

Use a gap (clearance) gauge for easy and accurate mea-

surement.

3. Loosen 4 plate mounting bolts (2) and loosen plate (3).

4. Remove shim (4) corresponding to the amount of play “a“

measured above.

[Example]

In the case of play of 3 mm, remove two 1.0 mm shims and

one 0.5 mm shim. Play becomes 0.5 mm. For shim (4), two

types of 1.0 mm and 0.5 mm are used.

When play “a“ is smaller than one shim, do not carry out

any maintenance.

5. Tighten the four bolts (2).

If the bolts (2) are too stiff to tighten, pull out pin stopper bolt (5) for easier tightening.

(6): Arm

(7): Bucket

Loading...

Loading...