301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

126

Cbeckinl

crankshaft

run-out

at

beari!!l

pin

~Ind.r

-

MlllasU-

cDltlnl

Cbackinw.maasurinl

cYlindar

40037&-10

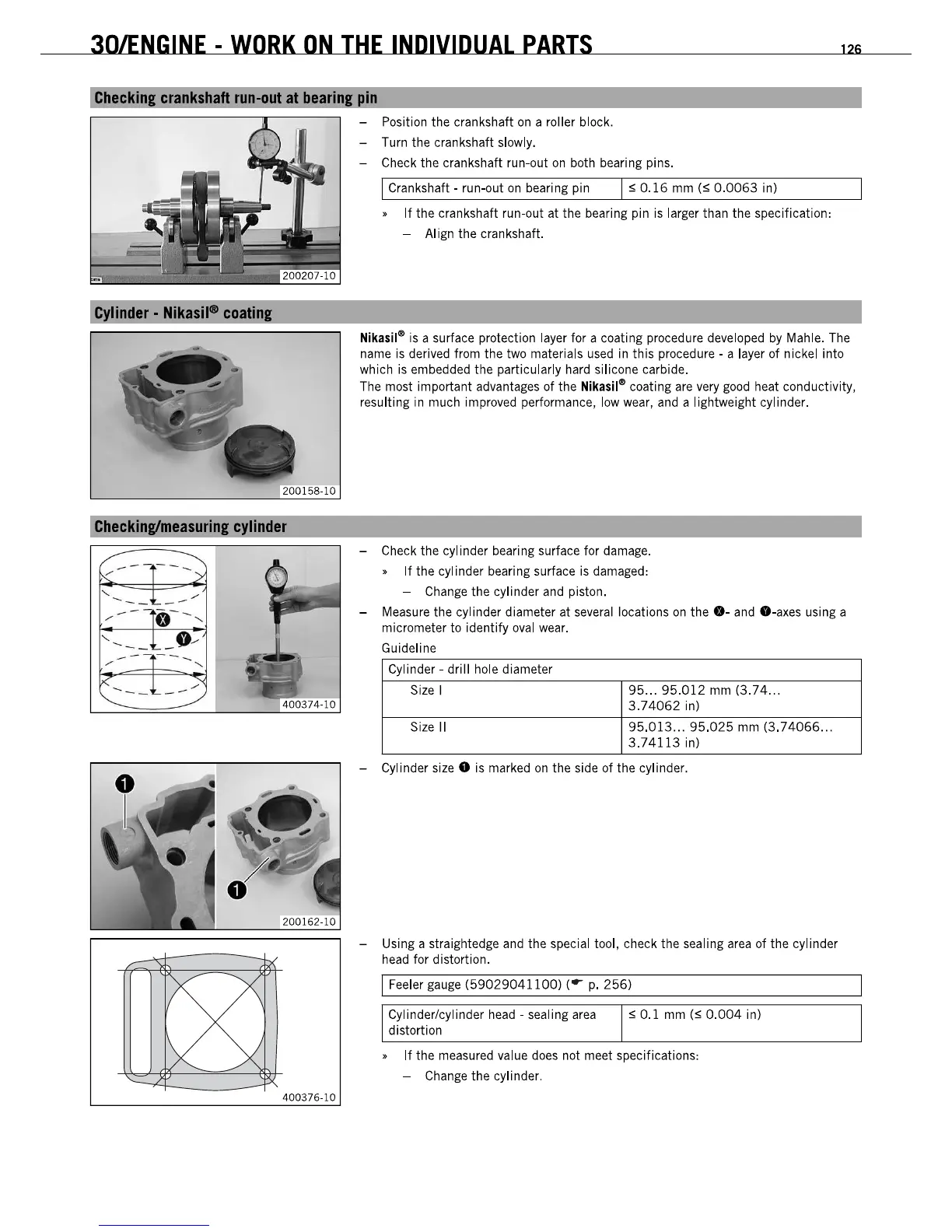

- Position the crankshaft

on

a roller block.

- Turn the crankshaft slowly.

- Check the crankshaft run-out

on

both bearing pins.

I Crankshaft - run-out

on

bearing pin I

,;

0.16

mm

(,;

0.0063

in)

•

If

the crankshaft run-out at the bearing pin is larger than the specification:

- Align the crankshaft.

Nikasil

e

is a surface protection layer for a coating procedure developed by Mahle. The

name is derived from the two materials

used

in this procedure - a layer of nickel into

which is embedded the particularly hard silicone carbide.

The most important advantages of the

Nikasil·

coating

are

very

good

heat conductivity,

resulting in much improved performance, low

wear,

and a lightweight cylinder.

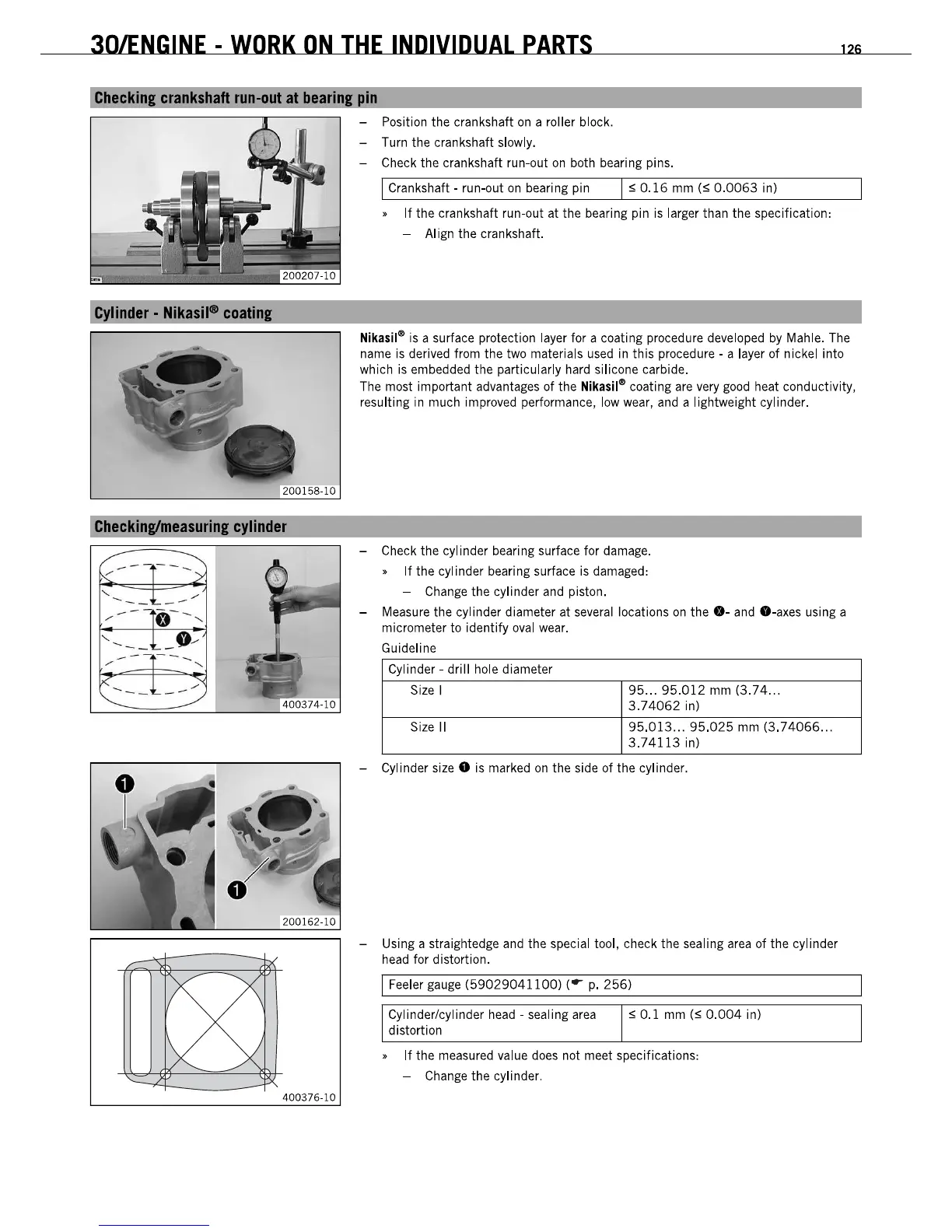

- Check the cylinder bearing surface for damage.

•

If

the cylinder bearing surface is damaged:

- Change the cylinder and piston.

- Measure the cylinder diameter at several locations

on

the

.-

and

.-axes

using a

micrometer to identify oval wear.

Guideline

CYlinder - drill hole diameter

Size I

Size II

95

...

95.012

mm

(3.74

...

3.74062

in)

95.013

...

95.025

mm

(3.74066

...

3.74113

in)

- Cylinder size

0 is marked

on

the side of the cylinder.

- Using a straightedge and the special tool, check the sealing area of the cylinder

head

for distortion.

I Feeler gauge

(59029041100)

(

.-

p.

256)

cylinder/cylinder head - sealing

area

distortion

,; 0.1

mm

(,;

0.004

in)

•

If

the measured value does not meet specifications:

- Change the cylinder.

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

126

Cbeckinl

crankshaft

run-out

at

beari!!l

pin

~Ind.r

-

MlllasU-

cDltlnl

Cbackinw.maasurinl

cYlindar

40037&-10

- Position the crankshaft

on

a roller block.

- Turn the crankshaft slowly.

- Check the crankshaft run-out

on

both bearing pins.

I Crankshaft - run-out

on

bearing pin I

,;

0.16

mm

(,;

0.0063

in)

•

If

the crankshaft run-out at the bearing pin is larger than the specification:

- Align the crankshaft.

Nikasil

e

is a surface protection layer for a coating procedure developed by Mahle. The

name is derived from the two materials

used

in this procedure - a layer of nickel into

which is embedded the particularly hard silicone carbide.

The most important advantages of the

Nikasil·

coating

are

very

good

heat conductivity,

resulting in much improved performance, low

wear,

and a lightweight cylinder.

- Check the cylinder bearing surface for damage.

•

If

the cylinder bearing surface is damaged:

- Change the cylinder and piston.

- Measure the cylinder diameter at several locations

on

the

.-

and

.-axes

using a

micrometer to identify oval wear.

Guideline

CYlinder - drill hole diameter

Size I

Size II

95

...

95.012

mm

(3.74

...

3.74062

in)

95.013

...

95.025

mm

(3.74066

...

3.74113

in)

- Cylinder size

0 is marked

on

the side of the cylinder.

- Using a straightedge and the special tool, check the sealing area of the cylinder

head

for distortion.

I Feeler gauge

(59029041100)

(

.-

p.

256)

cylinder/cylinder head - sealing

area

distortion

,; 0.1

mm

(,;

0.004

in)

•

If

the measured value does not meet specifications:

- Change the cylinder.

Loading...

Loading...