301ENGINE

ASSEMBLY

Installinl

til.

rotor

Installinl

til.

p'iston

153

- Slip

in

the timing chain guide

rail.

from above. Mount

and

tighten screws

•.

Guideline

Screw, timing chain guide M6

8Nm

Loctile-

243""

rail

(5.9

Ibf

It)

- Mount balance weight

•.

_

Info

I The shape of the gear

mesh

makes

it

impossible to mount the balance

weight incorrectly.

- Mount lock washer

and

nut. Tighten the nut.

Guideline

Balancer shaft nut

MlOxl

- Secure the nut with the lock washer.

40

Nm

(29.5

Ibf ft)

- Ensure that the spring washers

are

seated properly. Mount the rotor.

- Mount and tighten the spring washer

and

nut.

Tighten the nut.

Guideline

I Nut, rotor

I

M12x1

160

Nm

~44.3

Ibf ft)

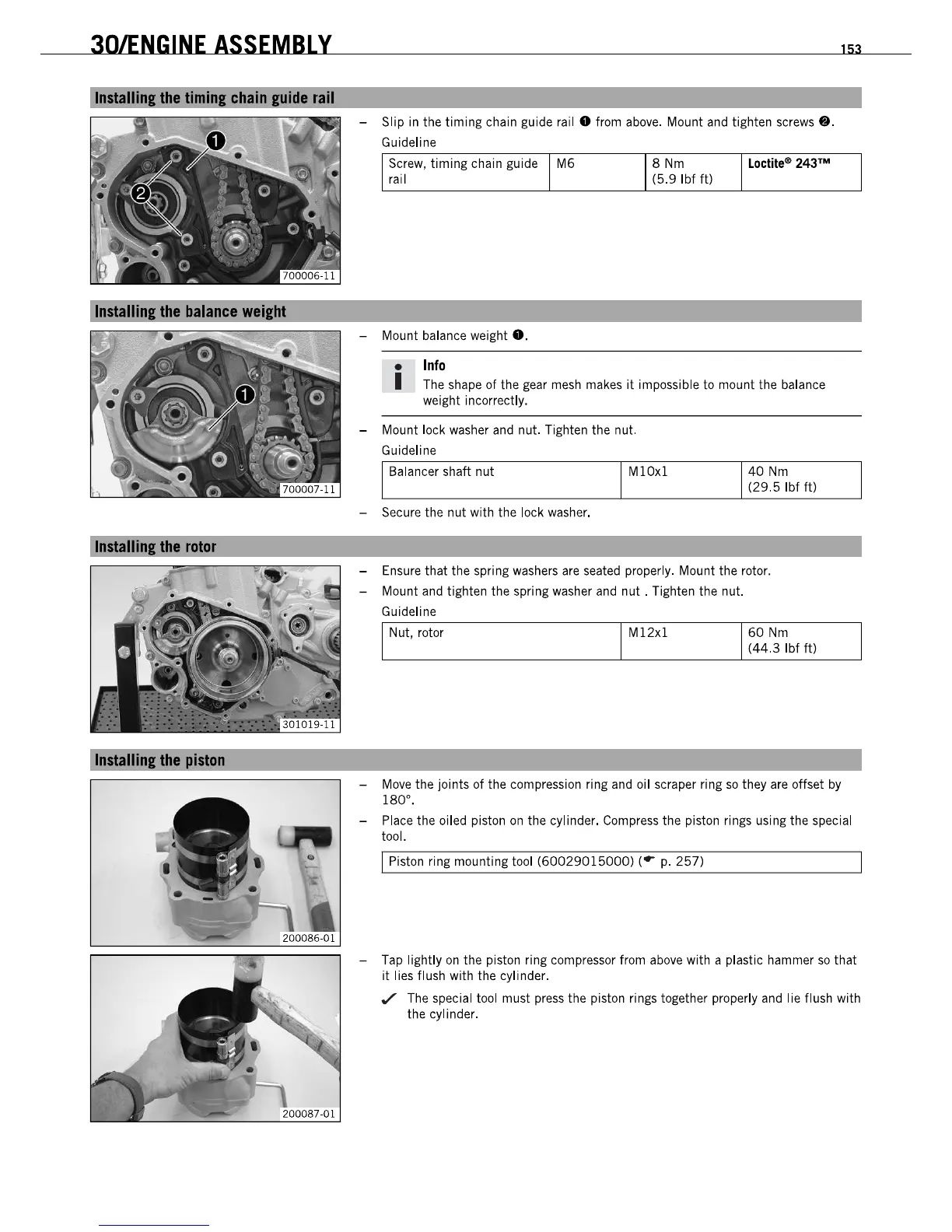

-

Move

the joints

of

the compression ring

and

oil scraper ring

so

they are offset

by

180'.

- Place the oiled piston

on

the cylinder. Compress the piston rings using the special

tool.

I Piston ring mounting tool

(60029015000)

(

--

p.

257)

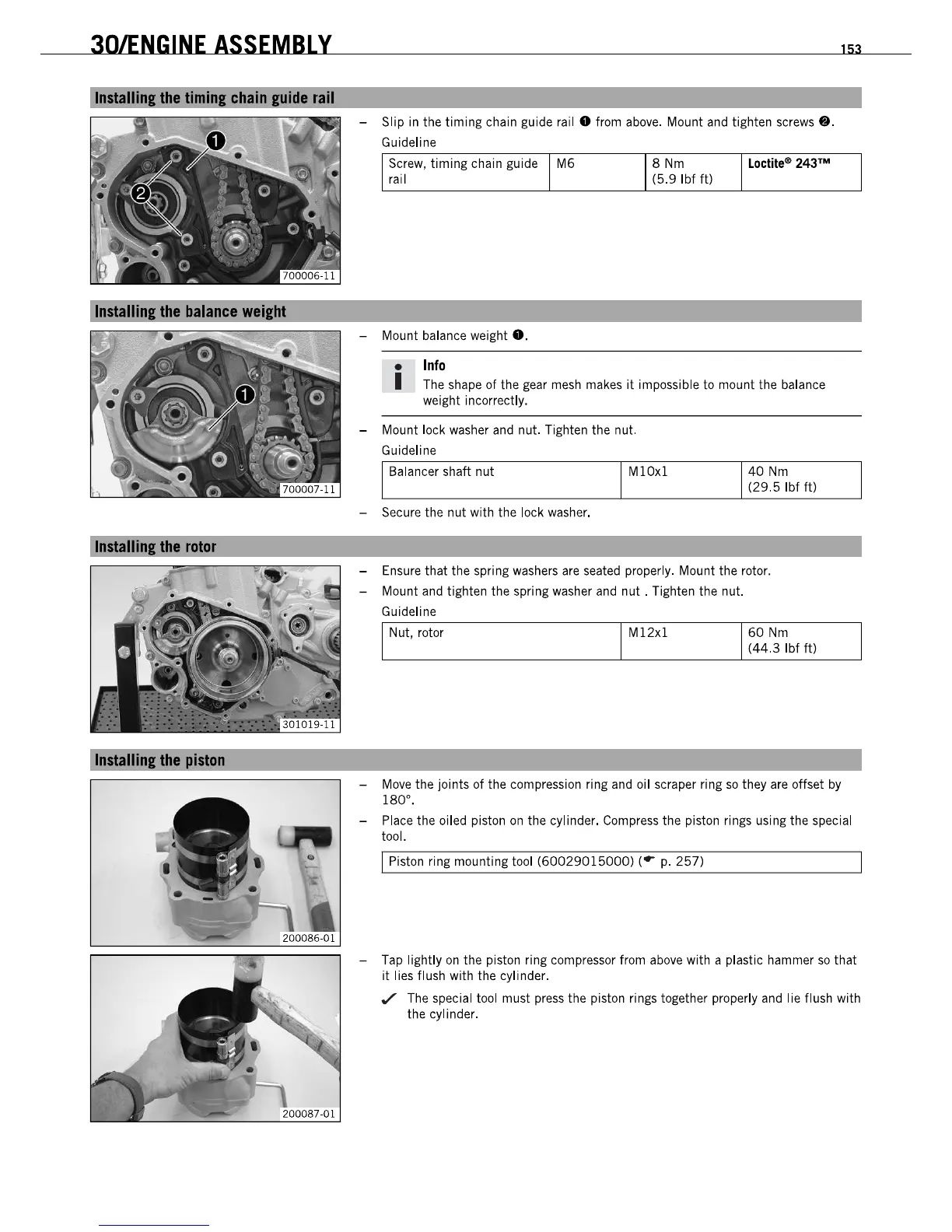

- Tap lightly

on

the piston ring compressor from

above

with a plastic hammer

so

that

it

lies flush with the cylinder.

,/

The special tool must

press

the piston rings together properly

and

lie flush with

the cylinder.

301ENGINE

ASSEMBLY

Installinl

til.

rotor

Installinl

til.

p'iston

153

- Slip

in

the timing chain guide

rail.

from above. Mount

and

tighten screws

•.

Guideline

Screw, timing chain guide M6

8Nm

Loctile-

243""

rail

(5.9

Ibf

It)

- Mount balance weight

•.

_

Info

I The shape of the gear

mesh

makes

it

impossible to mount the balance

weight incorrectly.

- Mount lock washer

and

nut. Tighten the nut.

Guideline

Balancer shaft nut

MlOxl

- Secure the nut with the lock washer.

40

Nm

(29.5

Ibf ft)

- Ensure that the spring washers

are

seated properly. Mount the rotor.

- Mount and tighten the spring washer

and

nut.

Tighten the nut.

Guideline

I Nut, rotor

I

M12x1

160

Nm

~44.3

Ibf ft)

-

Move

the joints

of

the compression ring

and

oil scraper ring

so

they are offset

by

180'.

- Place the oiled piston

on

the cylinder. Compress the piston rings using the special

tool.

I Piston ring mounting tool

(60029015000)

(

--

p.

257)

- Tap lightly

on

the piston ring compressor from

above

with a plastic hammer

so

that

it

lies flush with the cylinder.

,/

The special tool must

press

the piston rings together properly

and

lie flush with

the cylinder.

Loading...

Loading...