301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

Cbeckin

w.m

easulinlllle

piston

Cbacklnllha

piston

Ilnl

and

lap

- Check the piston sliding surface for damage.

•

If

the piston sliding surface

is

damaged:

- Replace the piston and,

if

necessary, the cylinder.

- Check

that

the piston rings move easily in the piston ring grooves.

•

If

a piston ring exhibits excessive resistance:

- Clean the piston ring groove.

•

Tip

I

An

old piston ring can

be

used

to

clean the piston ring groove.

- Check the piston rings for damage.

•

If

the piston ring is damaged:

- Replace the piston ring.

•

Info

I Mount the piston ring with the marking facing upward.

- Check the piston pins for discoloration or signs of wear.

•

If

the piston pin shows severe discoloration/signs of wear:

- Replace the piston pin.

- Place the piston pin in the connecting

rod

and check the seating for play.

•

If

the piston pin seating has excessive play:

- Replace the connecting

rod

and piston pin.

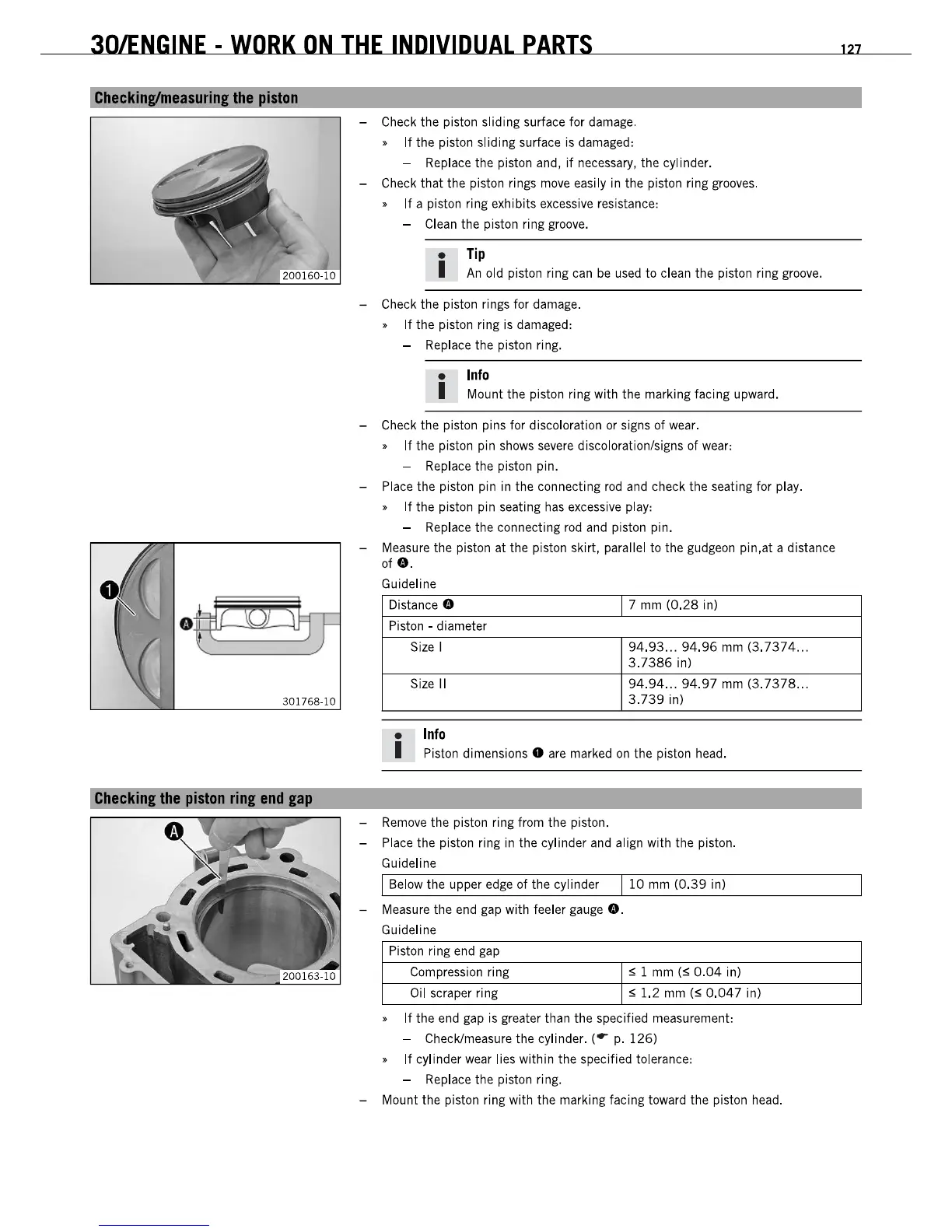

- Measure the piston at the piston skirt, parallel to the gudgeon pin,at a distance

of

•.

Guideline

Distance.

7 mm (0.28 in)

Piston - diameter

Size I

94.93

...

94.96

mm (3.7374 ...

3.7386

in)

Size II

94.94

...

94.97

mm (3.7378 ...

3.739

in)

•

Info

I Piston dimensions 0 are marked

on

the piston head.

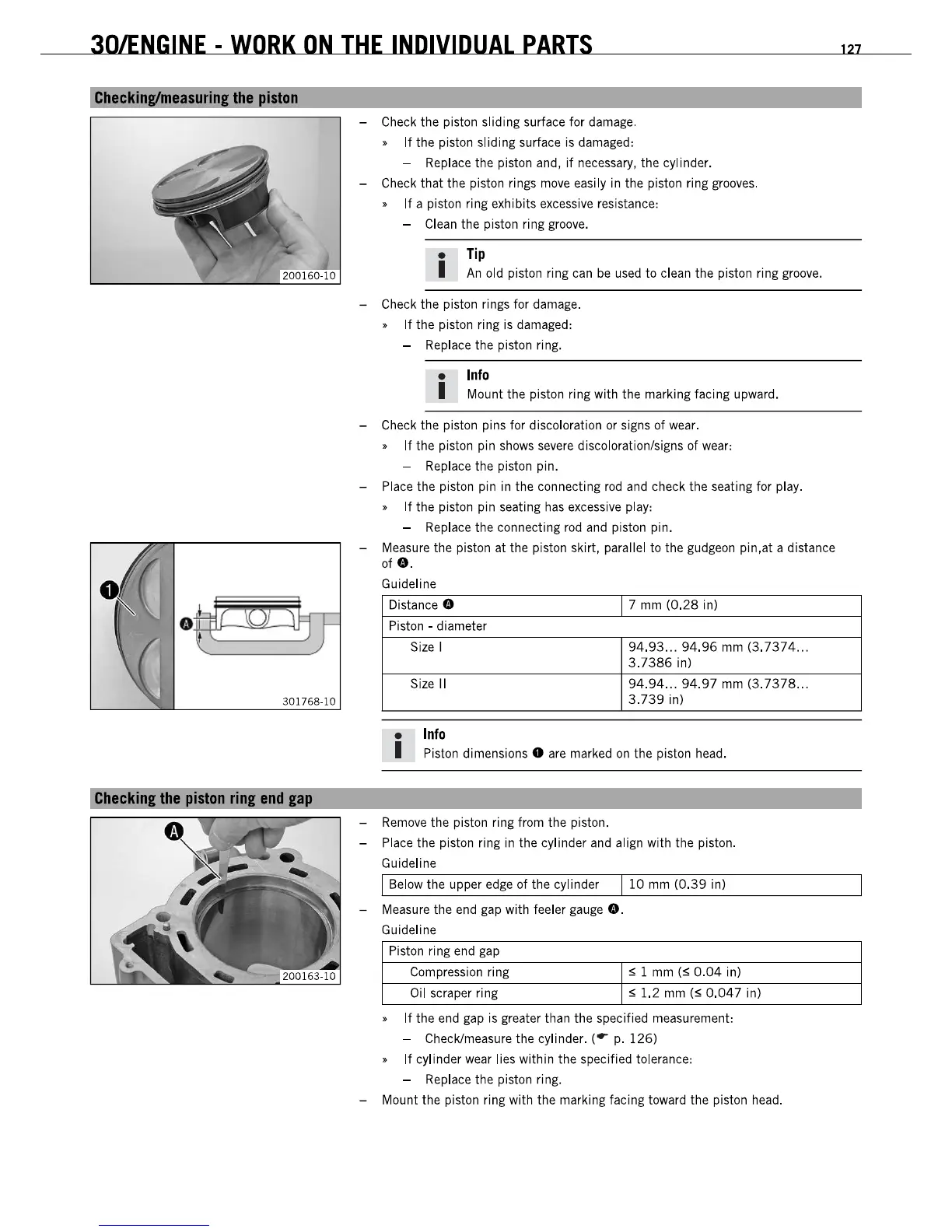

- Remove the piston ring from the piston.

- Place the piston ring in the cylinder and align with the piston.

Guideline

I Below the upper edge

of

the cylinder 110 mm (0.39 in)

- Measure the end gap with feeler gauge

•.

Guideline

Piston ring end gap

Compression ring

,; 1 mm (,;

0.04

in)

Oil scraper ring

,; 1.2 mm (,; 0.047 in)

•

If

the end gap is greater than the specified measurement:

- Check/measure the cylinder. (

..

p.

126)

•

If

cylinder wear lies within the specified tolerance:

- Replace the piston ring.

- Mount the piston ring with the marking facing toward the piston head.

127

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

Cbeckin

w.m

easulinlllle

piston

Cbacklnllha

piston

Ilnl

and

lap

- Check the piston sliding surface for damage.

•

If

the piston sliding surface

is

damaged:

- Replace the piston and,

if

necessary, the cylinder.

- Check

that

the piston rings move easily in the piston ring grooves.

•

If

a piston ring exhibits excessive resistance:

- Clean the piston ring groove.

•

Tip

I

An

old piston ring can

be

used

to

clean the piston ring groove.

- Check the piston rings for damage.

•

If

the piston ring is damaged:

- Replace the piston ring.

•

Info

I Mount the piston ring with the marking facing upward.

- Check the piston pins for discoloration or signs of wear.

•

If

the piston pin shows severe discoloration/signs of wear:

- Replace the piston pin.

- Place the piston pin in the connecting

rod

and check the seating for play.

•

If

the piston pin seating has excessive play:

- Replace the connecting

rod

and piston pin.

- Measure the piston at the piston skirt, parallel to the gudgeon pin,at a distance

of

•.

Guideline

Distance.

7 mm (0.28 in)

Piston - diameter

Size I

94.93

...

94.96

mm (3.7374 ...

3.7386

in)

Size II

94.94

...

94.97

mm (3.7378 ...

3.739

in)

•

Info

I Piston dimensions 0 are marked

on

the piston head.

- Remove the piston ring from the piston.

- Place the piston ring in the cylinder and align with the piston.

Guideline

I Below the upper edge

of

the cylinder 110 mm (0.39 in)

- Measure the end gap with feeler gauge

•.

Guideline

Piston ring end gap

Compression ring

,; 1 mm (,;

0.04

in)

Oil scraper ring

,; 1.2 mm (,; 0.047 in)

•

If

the end gap is greater than the specified measurement:

- Check/measure the cylinder. (

..

p.

126)

•

If

cylinder wear lies within the specified tolerance:

- Replace the piston ring.

- Mount the piston ring with the marking facing toward the piston head.

127

Loading...

Loading...