30lENGINE

ASSEMBLY

145

-

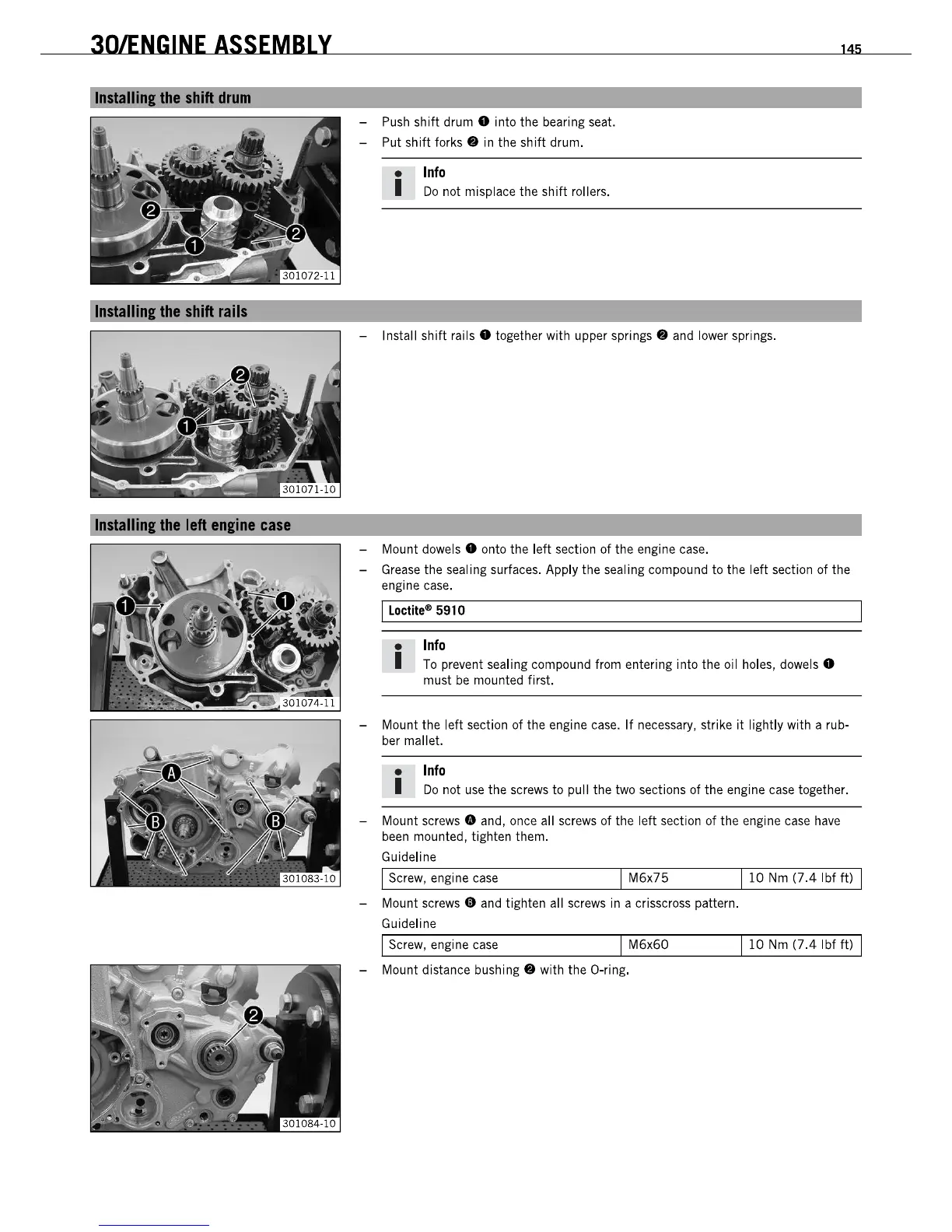

Push

shift drum 0 into the bearing seat.

- Put shift

forks.

in

the shift drum.

•

Info

I

Do

not misplace the shift rollers.

- Install shift rails

0 together with upper

springs.

and lower springs.

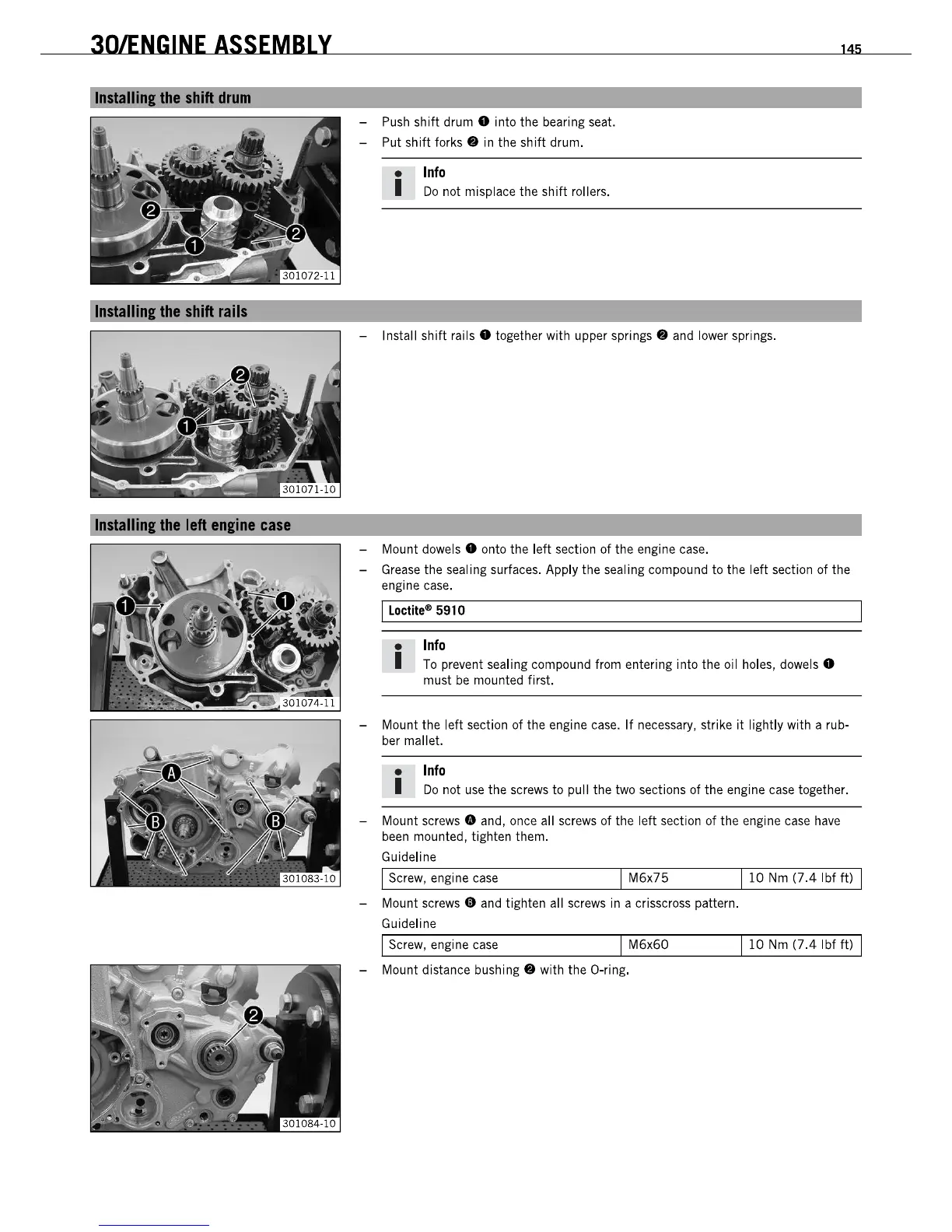

- Mount dowels

0 onto the left section of the engine case.

-

Grease

the sealing surfaces. Apply the sealing compound to the left section of the

engi

ne

case.

I

Loctite-

5910

•

Info

I

To

prevent sealing compound from entering into the oil holes, dowels 0

must

be

mounted first.

- Mount the left section of the engine

case.

If

necessary, strike

it

lightly with a rub-

ber

mallet.

•

Info

I

Do

not

use

the screws to pull the two sections of the engine

case

together.

- Mount

screws.

and, once all screws of the left section of the engine

case

have

been

mounted, tighten them.

Guideline

I Screw, engine

case

I M6x75

110

Nm

(7.4

Ibf

ftl

I

- Mount

screws.

and tighten all screws

in

a crisscross pattern.

Guideline

I Screw, engine

case

I M6x60

110

Nm

(7.4

Ibf

ftl

I

- Mount distance

bushing.

with the O-ring.

30lENGINE

ASSEMBLY

145

-

Push

shift drum 0 into the bearing seat.

- Put shift

forks.

in

the shift drum.

•

Info

I

Do

not misplace the shift rollers.

- Install shift rails

0 together with upper

springs.

and lower springs.

- Mount dowels

0 onto the left section of the engine case.

-

Grease

the sealing surfaces. Apply the sealing compound to the left section of the

engi

ne

case.

I

Loctite-

5910

•

Info

I

To

prevent sealing compound from entering into the oil holes, dowels 0

must

be

mounted first.

- Mount the left section of the engine

case.

If

necessary, strike

it

lightly with a rub-

ber

mallet.

•

Info

I

Do

not

use

the screws to pull the two sections of the engine

case

together.

- Mount

screws.

and, once all screws of the left section of the engine

case

have

been

mounted, tighten them.

Guideline

I Screw, engine

case

I M6x75

110

Nm

(7.4

Ibf

ftl

I

- Mount

screws.

and tighten all screws

in

a crisscross pattern.

Guideline

I Screw, engine

case

I M6x60

110

Nm

(7.4

Ibf

ftl

I

- Mount distance

bushing.

with the O-ring.

Loading...

Loading...